In the vibrant landscape of custom apparel printing, DTF transfers have emerged as a groundbreaking technology, redefining the way we approach printed clothing. This innovative Direct-to-Film process stands out due to its ability to produce high-quality, detailed designs that adhere effortlessly to a variety of textiles. As businesses and consumers increasingly prioritize sustainability, DTF printing offers an eco-friendly alternative that minimizes waste and promotes responsible production practices. With its efficiency and versatility, DTF transfers are not only revolutionizing the industry but also ensuring that personalized apparel meets the modern demands of quality and sustainability. In this article, we will dive deeper into the benefits and innovations surrounding DTF transfers and their growing role in shaping the future of custom apparel.

As we explore the dynamics of printing technologies, DTF transfers, also known as Direct-to-Film prints, are at the forefront of contemporary methods for creating customized clothing. This advanced printing technique utilizes a specialized film for meticulous detail, promising vibrant results on various fabric types. In today’s eco-conscious environment, the rising preference for sustainable printing solutions has made DTF printing a favored choice among creators and businesses alike. Additionally, its adaptability for both small batch and large production runs provides a competitive edge in the market of printed apparel. By understanding alternative terms and concepts surrounding DTF, we can appreciate the depth and significance of this innovative approach to custom apparel production.

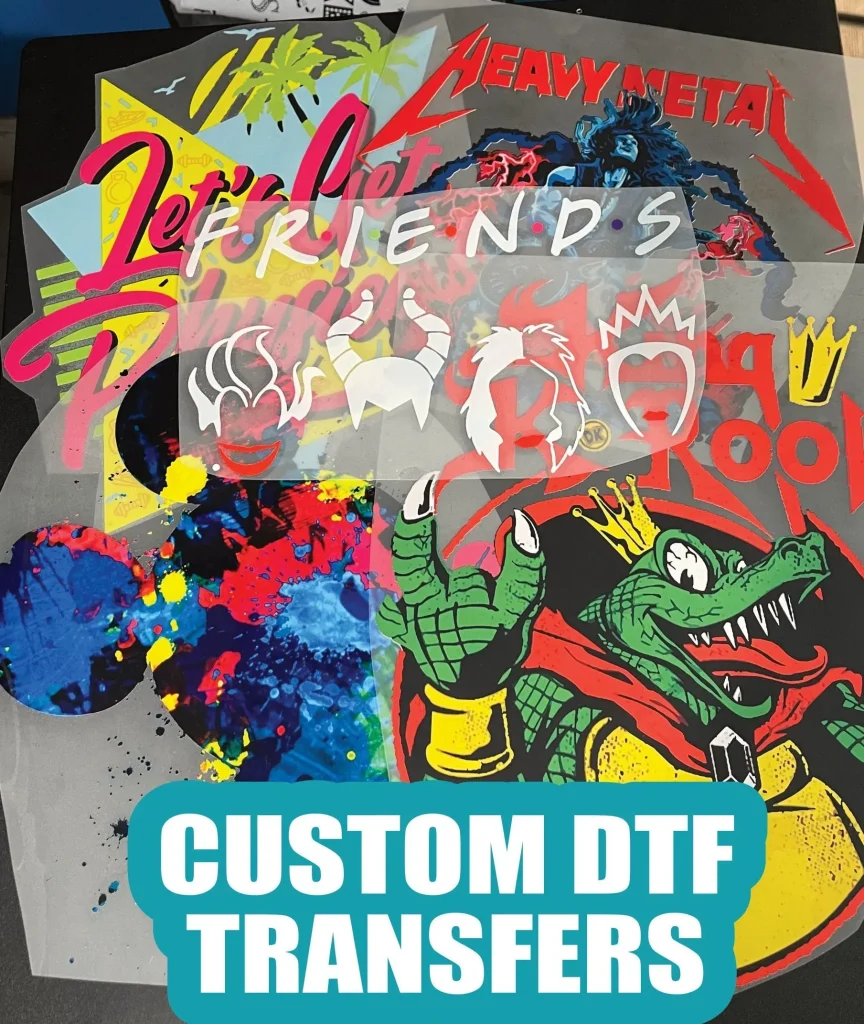

Understanding the DTF Transfers Process

DTF (Direct-to-Film) transfers involve a unique printing method where intricate designs are printed onto a special film before being transferred to fabric. This process begins with printing high-resolution graphics onto a film using specialized DTF inks. Once the design is complete, a heat transfer process is applied, which allows the adhesive through the printed film to bond with the fabric. The result is a vibrant and durable print that can adhere to a wide range of textiles, from cotton to blended fabrics.

One of the key advantages of the DTF process is its flexibility. Unlike traditional screen printing, which often requires extensive setup for each design, DTF printing can swiftly adapt to various designs without the need for multiple screens. This efficiency is particularly beneficial for small businesses and creators looking to produce custom apparel quickly without compromising on quality or detail.

Eco-Friendly Advantages of DTF Printing

As the demand for sustainable printing solutions increases, DTF printing stands out with its eco-friendly practices. The process uses water-based inks that emit fewer volatile organic compounds (VOCs) compared to many traditional printing methods. This not only reduces the environmental impact during the production phase but also contributes to a healthier workplace for those involved in the printing process.

Moreover, DTF printing minimizes material waste. Unlike methods that involve cutting or stamping excess material, DTF allows for precise designs that are transferred onto fabric, effectively optimizing material usage. As consumers become more aware of sustainability, businesses adopting DTF technology can position themselves as leaders in responsible manufacturing.

The Versatility of DTF Printing

One of the standout features of DTF printing is its versatility in application. This method can be used on a variety of fabrics, including cotton, polyester, and blends, making it suitable for diverse custom apparel needs. Whether producing t-shirts, hoodies, or even sportswear, DTF printing provides the flexibility needed to cater to different market demands without limiting creativity in design.

This adaptability opens opportunities not just for apparel but for accessories and promotional items as well. Businesses can diversify their offerings with custom prints on bags, caps, and home textiles, enhancing their product lines and appealing to a broader audience. As such, DTF printing serves as an invaluable tool for brands looking to explore new avenues in custom merchandise.

DTF Printing vs. Traditional Printing Methods

When comparing DTF printing to traditional methods such as screen printing and sublimation, the advantages of DTF become evident. For instance, DTF printing allows for full-color designs with intricate details and gradients that would be challenging to achieve with screen printing. Additionally, it’s possible to print on a wider range of materials without being limited to specific fabric types, unlike sublimation, which primarily works on polyester substrates.

Cost-effectiveness is another area where DTF shows superiority. With lower setup costs and faster turnaround times for small runs, businesses can efficiently manage their budget while still producing high-quality printed clothing. This financial flexibility is essential for smaller enterprises and startups aiming to offer unique designs without incurring prohibitive costs.

Emerging Trends in DTF Printing Technology

The DTF printing landscape is continuously evolving, with numerous advancements enriching its capabilities. One excellent trend is the integration of digital technology into the DTF process. New software platforms now allow designers to create and send their designs directly to printers, streamlining the production process significantly. This integration enhances workflow efficiency and empowers businesses to respond swiftly to market demands.

Additionally, companies are increasingly investing in high-end DTF printers that offer enhanced features such as faster printing speeds and improved print quality. These innovations not only enable shorter lead times but also support higher resolution prints, which are essential in a market that prioritizes quality. As the technology advances, it positions DTF printing as a frontrunner in custom apparel production.

Challenges and Solutions in DTF Printing

While DTF printing offers revolutionary benefits, it does come with its own set of challenges. One significant hurdle is the initial learning curve associated with mastering the technology. As new users adapt to the process, they may encounter issues related to print adhesion or color accuracy. However, numerous online tutorials and community resources have emerged to assist newcomers in overcoming these challenges.

Additionally, while the overall investment in DTF technology can be lower than traditional methods, the costs for high-quality printers and materials still represent an upfront expense. To mitigate this, businesses can consider starting small, investing in essential equipment, and gradually scaling as demand increases. By doing so, they can balance operational costs while still benefitting from the advantages of DTF printing.

Frequently Asked Questions

What are DTF Transfers in custom apparel printing?

DTF Transfers, or Direct-to-Film Transfers, are an innovative method in custom apparel printing where designs are printed onto a special film and then transferred to fabrics using heat and pressure. This process enables the creation of high-quality, vibrant prints on various materials, making it a versatile option for customized clothing.

How does the DTF printing process work?

The DTF printing process involves printing designs onto a PET film, applying an adhesive, and then using heat to transfer the design onto the fabric. This method not only produces durable prints but also allows for customization on different fabric types, such as cotton and polyester, making it ideal for personalized apparel.

What are the sustainability benefits of DTF printing?

DTF printing is considered a more sustainable option in the world of custom apparel due to its reduced waste, eco-friendly inks, and lower energy consumption compared to traditional screen printing methods. Brands focusing on sustainable printing practices find DTF an attractive choice to meet consumer demand for eco-conscious products.

How does DTF printing compare to sublimation for custom apparel?

Unlike sublimation, which primarily works on polyester fabrics, DTF printing is versatile and compatible with various fabric types, including cotton blends. This broad applicability makes DTF a preferred option for crafters and businesses creating custom apparel, offering more design possibilities.

What makes DTF Transfers cost-effective for custom apparel printing?

DTF Transfers are cost-effective primarily because they have lower setup costs, especially for small runs. The DTF printing process is less labor-intensive than traditional methods, reducing labor costs for businesses and making it an economical choice for custom apparel.

What challenges should I expect when using DTF printing?

While DTF printing offers numerous advantages, there are challenges such as a learning curve for newcomers to the technology and initial equipment costs, which can be higher for quality printers and supplies. However, resources and support are increasingly available to help users navigate these challenges.

| Key Point | Description |

|---|---|

| What is DTF Printing? | A modern printing process that transfers designs printed on a special film to textiles using heat and pressure. |

| Sustainability Focus | Reduces waste and uses eco-friendly inks, meeting consumer demand for sustainable products. |

| Expansion of Custom Services | New services are simplifying custom transfer printing, making it accessible for creators. |

| Innovations in Commercial Printing | Platforms like Snuggle DTF are helping businesses expand their services with DTF technology. |

| Investment in Capacity Expansion | Companies are expanding operations to enhance print quality and meet demand for quicker service. |

| Comparison with Sublimation | DTF supports a wider range of fabrics compared to the limitations of sublimation technology. |

| Benefits of DTF Printing | Offers versatility, cost-effectiveness, high-quality prints, and aligns with eco-friendly practices. |

| Challenges Faced | Includes a learning curve for new users and initial equipment costs. |

Summary

DTF transfers are revolutionizing the custom apparel printing industry with their sustainable approach, versatility, and innovative technology. This method not only allows for vibrant and detailed prints across a variety of fabrics, but also aligns with the growing consumer demand for eco-friendly production practices. As brands increasingly embrace DTF technology, they are not only enhancing their product offerings but also responding to the need for more sustainable solutions in apparel manufacturing. By investing in DTF transfers, businesses can streamline their operations, reduce waste, and engage with a broader audience eager for quality and customization. As this technology continues to evolve, it is poised to play a crucial role in shaping the future of custom apparel printing.