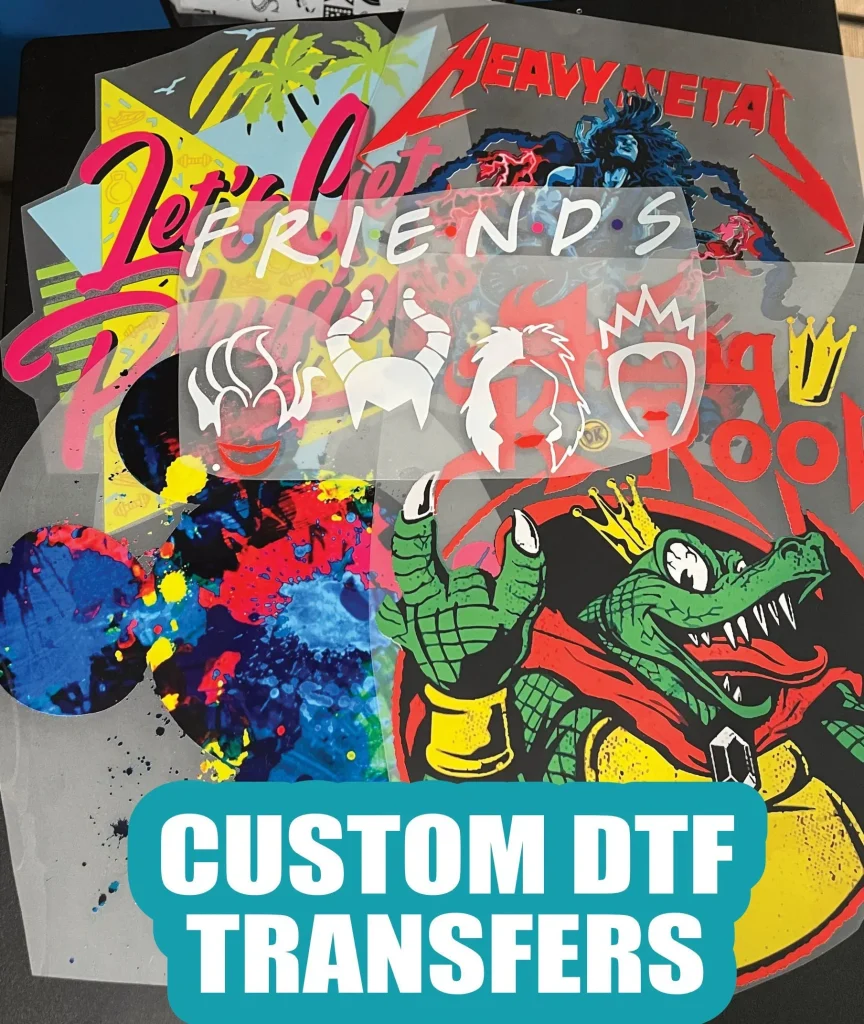

DTF transfers, or Direct to Film transfers, have revolutionized the landscape of custom apparel printing, allowing for more intricate designs and vibrant colors than ever before. This innovative DTF printing technology enables businesses to create high-quality outputs that cater to a variety of fabric types, enhancing the appeal of custom merchandise. Unlike traditional printing methods, DTF technology involves using special heat transfer film to ensure durability and precision in every print. As we explore the world of DTF transfers, we will uncover their numerous benefits and how they stand out in the competitive printing market. With the rise of DTF transfers, it’s an exciting time for custom apparel enthusiasts and professional printers alike.

Direct to Film (DTF) printing has emerged as a premier choice for those looking to create custom designs on apparel. Known for its versatility and efficiency, this advanced printing method utilizes specialized films for heat transfer, which guarantees stunning visual results. Often referred to as heat transfer films or custom decoration techniques, DTF printing has gained traction due to its ability to handle both small and large production runs seamlessly. The integration of DTF technology allows for a quick turnaround while maintaining exceptional quality, making it a favorite among entrepreneurs and established businesses in the apparel industry. Understanding the dynamics of DTF transfers will reveal why they are quickly becoming a staple in the realm of custom apparel.

Exploring DTF Printing Technology

DTF (Direct to Film) printing technology is revolutionizing the custom apparel printing industry. By allowing designers to create vivid and intricate prints on a special heat transfer film, DTF becomes an ideal choice to cater to a diverse range of fabrics. Unlike traditional methods like screen printing, which are often limited to specific material types and color palettes, DTF printing recognizes the needs for versatility, offering compatibility with various textiles, including cotton, polyester, and blends.

Moreover, DTF technology ensures that every design retains its vibrancy even after multiple washes, addressing one of the most common criticisms of conventional printing methods. This innovation not only appeals to large businesses looking for efficiency but also to small design studios that require flexibility in their productions. DTF printing represents a progressive shift in how artists and brands approach apparel design, elevating the possibilities for creativity in custom apparel.

The Process of Creating DTF Transfers

Creating DTF transfers involves several key steps that ensure quality outcomes. Initially, the process begins with the creation of an artwork design using sophisticated graphic design software, making it easier to achieve high-resolution images that capture all intricate details. Following this, the design is printed onto specialized DTF transfer film, requiring a printer specifically designed for DTF technology to obtain the best results.

Once the design is printed, the application process utilizes a heat press to apply heat and pressure to fuse the ink with the fabric. This essential step guarantees that the print adheres to the garment permanently. After cooling, the transfer film is carefully peeled away, leaving behind a vibrant, durable design. Observing these steps with precision is vital for anyone involved in custom apparel printing using DTF transfers.

Advantages of Using DTF Transfers

The rise in popularity of DTF transfers can be attributed to the numerous advantages they offer over other printing methods. One significant benefit is their versatility, as DTF transfers can be applied to a wide variety of fabrics, from cotton to polyester, allowing for an expanded range of products. This flexibility makes DTF a go-to choice for businesses looking to diversify their offerings without the need for multiple printing techniques.

In addition, DTF transfers provide exceptional durability. Unlike traditional prints that may crack or fade with time, DTF prints are engineered to withstand multiple washes and maintain their quality over the garment’s life. This longevity appeals to brands aiming to deliver high-quality products that will stand the test of time, further solidifying DTF technology as a durable option for custom apparel.

Recent Innovations in DTF Printing

Innovation remains at the forefront of DTF printing, demonstrated by recent developments from companies leading the industry. For instance, Sam’s DTF Transfers has recently launched their premium in-house services, focusing on high-quality printing techniques that leverage years of experience in the field. The introduction of in-house services allows businesses to maintain greater control over the quality and turnaround time of their custom apparel, ensuring that they can meet customer demands effectively.

Additionally, Insta Graphic Systems launched a new line of DTF heat transfers, showcasing advancements in the technology. Their product promises vibrant, durable prints that excel in maintaining color integrity and precision, evidencing the continuous evolution within the DTF landscape. Such innovations signal a shift towards higher efficiency and quality, enhancing the overall experience for businesses engaged in custom printing.

Essential Materials for DTF Printing

To achieve optimal results in DTF printing, understanding the essential materials is crucial. The backbone of this innovative method is the DTF printer, specifically designed to work with unique inks that are compatible with heat transfer film. Investing in a high-quality DTF printer guarantees vibrant prints that meet industry standards and allows for scaling operations as demand grows.

Another vital component is the DTF transfer film itself, which uniquely adheres the ink to the fabric during the transfer process. Selecting the right film can make a significant difference in the final product’s quality, durability, and ease of application. Lastly, a reliable heat press is necessary for fusing the design onto the garment efficiently. Together, these materials ensure that DTF printing remains a competitive option in the custom apparel market.

Learning Resources for DTF Printing

For those eager to expand their knowledge of DTF printing, a plethora of resources are available online. Various tutorials and guides offer insightful step-by-step instructions that cover everything from setting up the DTF printing process to executing high-quality transfers. Many printing supply companies provide comprehensive guides to help novices and professionals alike navigate the complexities of DTF technology.

Moreover, engaging with online communities dedicated to DTF printing can provide invaluable peer support and insights. These forums serve as platforms for sharing experiences, discussing challenges, and showcasing successful projects, promoting a learning environment for both beginners and seasoned printers. By leveraging these resources, individuals can stay updated on industry trends and advancements in DTF printing technology.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film Transfers, are a printing method where designs are printed on a specialized heat transfer film. This film is then applied to garments using heat and pressure, creating vibrant and durable prints ideal for custom apparel.

What are the benefits of using DTF printing for custom apparel?

DTF printing offers several advantages for custom apparel, including versatility across different fabric types, durability that ensures prints resist fading or cracking, and cost-effectiveness for small batch orders compared to traditional methods like screen printing.

What materials are needed for DTF Transfers?

To successfully create DTF Transfers, you need a DTF printer compatible with specific inks, DTF transfer film for applying designs, and a heat press for adhering the prints to the fabric. These components are essential for high-quality results in direct to film printing.

Can DTF Transfers be used on various fabric types?

Yes! DTF Transfers are versatile and can be applied to a wide range of fabrics, including cotton, polyester, and fabric blends, making them suitable for many custom apparel applications.

How does the DTF transfer process differ from traditional screen printing?

The DTF transfer process involves printing designs onto a film that is then heat pressed onto garments, allowing for intricate details and vibrant colors. In contrast, traditional screen printing uses stencils and can be less flexible for complex designs or small batches.

Where can I find resources to learn more about DTF technology?

Many online resources, including tutorials from printing supply companies and industry forums, provide comprehensive guides on DTF technology. Joining online communities dedicated to DTF printing can also enhance your understanding and keep you updated on trends.

| Aspect | Description |

|---|---|

| What is DTF Printing? | A method where designs are transferred onto a heat transfer film, which is then applied to garments using heat and pressure. |

| Recent Developments | Highlights include new premium services from Sam’s DTF Transfers and the innovative DTF heat transfers from Insta Graphic Systems. |

| Key Components of DTF Transfers | Essential items include a DTF printer, DTF transfer film, and a heat press for applying pressure and heat during transfer. |

| Applications | Suitable for custom apparel, promotional items, and merchandise that require detailed and vibrant designs. |

| Advantages | Benefits include versatility, durability against wash and wear, and cost-effectiveness compared to traditional printing methods. |

Summary

DTF transfers have emerged as a revolutionary technique within the world of custom apparel printing. This innovative method allows for vibrant, high-quality designs that can be applied to a wide range of fabrics, making it a desirable option for businesses and individuals alike. Understanding the intricacies of DTF transfers, including recent developments and the key materials involved, is essential for anyone looking to make their mark in the printing industry. As technology continues to advance, DTF transfers are not just changing how we print; they are redefining the possibilities of custom apparel.