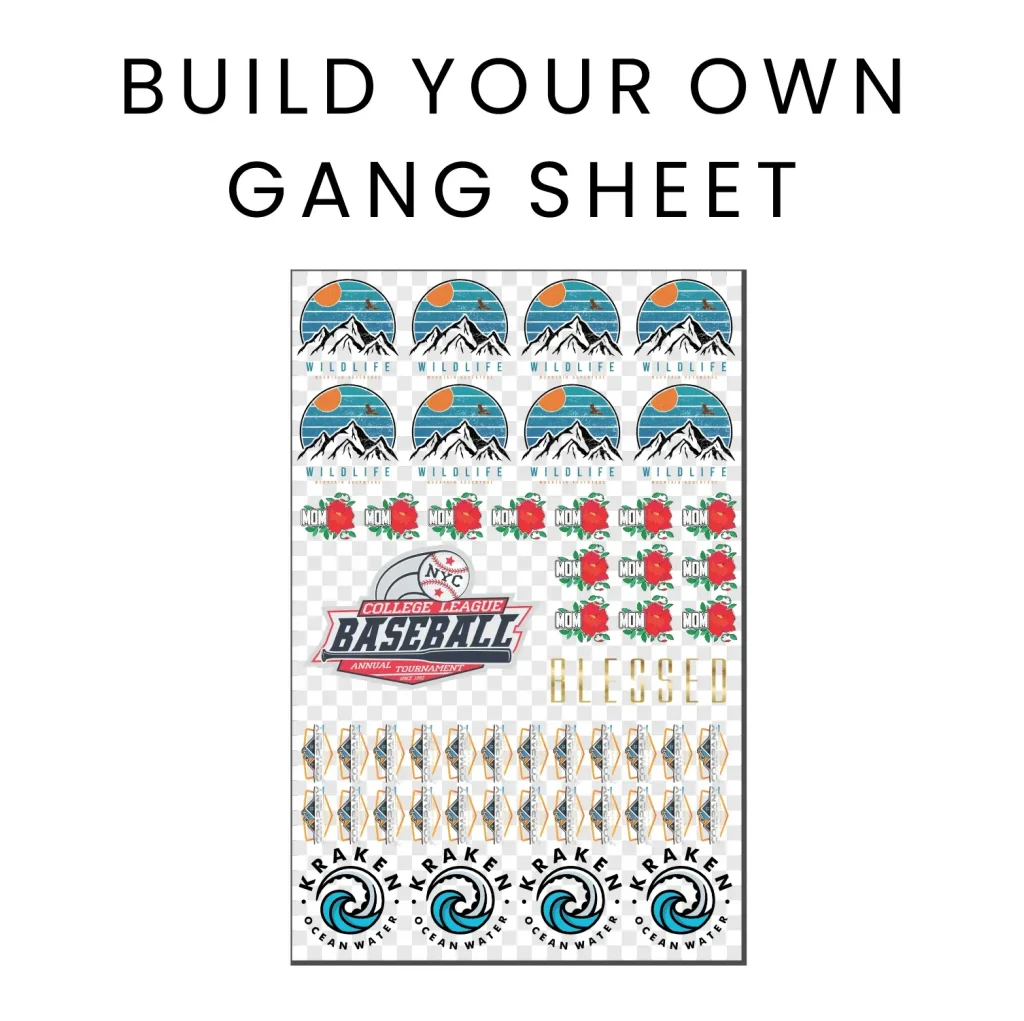

Welcome to the world of DTF Gangsheet Builder, where creativity meets efficiency in Direct-to-Film (DTF) printing! This innovative tool allows you to optimize your printing process by creating gang sheets that maximize material usage and minimize costs. Whether you’re new to DTF printing techniques or looking to refine your skills, understanding how to leverage a DTF gangsheet builder is essential for achieving professional-quality results. In this guide, we will explore the art of creating gang sheets, providing you with tips on mastering DTF gangsheet optimization. Get ready to transform your printing projects and enjoy the benefits of this efficient printing method!

Dive into the realm of Direct-to-Film (DTF) printing, where mastering the art of constructing gang sheets can elevate your printing game. The process of generating efficient layouts that feature multiple designs in a single print run is termed “Creating gang sheets” in the world of custom apparel and merchandise. By exploring various “DTF printing techniques,” you can increase productivity while reducing waste and operating costs. This introduction highlights the importance of employing effective strategies within your DTF gangsheet builder, paving the way for optimizing your print production. Elevate your projects today by embracing the advantages of DTF gangsheet optimization!

Understanding DTF Printing Technique

Direct-to-Film (DTF) printing has gained popularity due to its versatility and efficiency. This innovative printing technique allows for high-quality designs to be transferred onto a variety of fabrics, making it an ideal choice for custom apparel and promotional products. At its core, DTF printing involves applying designs onto a special film, which is then transferred onto the fabric using heat and pressure. This method enables intricate designs to be printed with rich colors and exceptional detail, without the limitations of traditional screen printing.

Moreover, mastering the DTF printing technique can significantly reduce the costs associated with run-length production. Unlike traditional methods that require separate screens for each color, DTF printing utilizes a single transfer film for multiple designs. This means better use of resources and less waste, enhancing productivity. Furthermore, DTF printing is not only suitable for fabric types like cotton and polyester but also works effortlessly with blends, making it an essential knowledge area for aspiring printers.

Creating Gang Sheets for Maximum Efficiency

Creating effective gang sheets is crucial in maximizing the printing area and reducing costs, making DTF printing more profitable. Gang sheets are composed of numerous designs arranged on a single sheet of film to be printed simultaneously. This layout strategy minimizes wasted space and ink, allowing for multiple unique designs to be produced in one go. By tightly packing designs—considering the necessary spacing for transfers—you make the best use of your film, ultimately leading to higher yields for your printing projects.

To effectively create gang sheets, it’s vital to utilize vector graphic software for accurate scaling and positioning of your designs. Not only does this ensure high-resolution outputs, but it also provides flexibility in arranging designs to optimize the space available. A well-planned gang sheet not only reduces costs but also streamlines production processes, making it an indispensable tool in any DTF printer’s arsenal. Efforts put into creating a solid gang sheet setup ultimately pay off in improved workflow and clearer prints.

Optimizing DTF Gangsheet Builder Workflows

Optimizing your DTF gangsheet builder is a critical step in enhancing your printing workflow. When utilizing this tool, ensure that your designs are adjusted for optimal output size while accounting for the capabilities of your printer. The layout within the builder should be strategically managed to prevent over-spilling or misalignment during the transfer process. Consideration of fabric types and necessary spacing techniques will also bolster the efficiency of your prints, making the gangsheet setup faster and more effective.

Additionally, regularly reviewing and updating your workflows based on feedback and print results can lead to continuous improvements. This involves understanding the specificities of the DTF printing technique and adapting your materials and settings accordingly. Evaluating the performance of previous gang sheets can yield insights necessary for making adjustments in the future, ensuring that your DTF gangsheet builder remains a powerful asset in your printing operations.

Choosing the Right Materials for DTF Printing

Material selection is vital in DTF printing success. The quality of DTF films and inks directly influences the final product’s appearance and durability. High-quality transfer films should be prioritized, as they are engineered specifically for DTF processes, ensuring that the final prints adhere well and retain clarity over time. For various fabrics, such as cotton and polyester blends, the type of film and ink must be compatible to prevent burning or poor adhesion during the curing process.

Moreover, the choice of adhesive powder cannot be overlooked. Selecting the right type of adhesive powder for your films ensures that inks bond correctly to the fabric, enhancing the longevity of the print. Regular experimentation with different material combinations can help identify the most advantageous setups for your specific printing needs, further guiding you in achieving vibrant, durable designs that stand the test of time.

Printer Configuration for Optimal Results

Printer settings play a crucial role in the output quality of your DTF prints. Adjusting ink saturation levels has a significant impact, as excessive ink can lead to smudging, while too little can result in an inconsistent print appearance. Striking the right balance for your specific designs is essential; it often involves running a series of test prints to fine-tune saturation and ensure that colors appear true-to-life without sacrificing clarity.

Resolution settings are another important aspect of printer configuration. While higher resolutions yield better-quality images, they can also prolong printing time. Therefore, finding an optimal balance between quality and efficiency is key. Maintaining regular printer head maintenance is equally critical, as this ensures consistent ink flow and print quality. These adjustments can make the difference between an ordinary print and one that showcases excellence in detail and vibrancy.

Post-Processing Techniques for Quality Assurance

The post-processing stage is where your DTF prints can either flourish or falter. After printing, the application of adhesive powder is essential; ensuring even coverage is paramount for effective adhesion. It’s recommended to apply the powder while the prints are still warm, as this supports better bonding to the ink. Successful powdering prepares your prints for the next critical step, enhancing the longevity and quality of the final product.

Following the application of the adhesive powder, proper curing methods must be implemented. Each material type has specific temperature and duration criteria that should be meticulously followed to ensure durability post-transfer. Utilizing a heat press and adhering to the manufacturer’s guidelines will help in achieving optimal results. After curing, always inspect your prints for any misalignments or defects before finalizing your products, as this final touch ensures that quality is maintained throughout the entire printing process.

Frequently Asked Questions

What is the DTF gangsheet builder and how does it work?

The DTF gangsheet builder is a tool designed for creating efficient layouts of multiple designs on a single film for Direct-to-Film (DTF) printing. It allows users to optimize the arrangement of graphics, minimizing waste and maximizing the use of printing area. By utilizing this builder, you can create gang sheets that print several designs simultaneously, reducing costs and improving workflow efficiency.

How can I optimize my DTF gangsheet for better print quality?

To optimize your DTF gangsheet for better print quality, ensure that your designs are correctly sized and utilize high-resolution graphics. Use appropriate vector graphics software, minimize empty spaces between designs for efficient layout packing, and select high-quality DTF films and inks. Proper printer settings, such as ink saturation and resolution, are also crucial in achieving excellent print results.

What materials are best for DTF gangsheet printing?

For DTF gangsheet printing, the best materials include high-quality DTF transfer films and vibrant, durable inks specifically designed for DTF printing. It is essential to choose adhesive powder that complements both the film and ink for effective adherence to fabrics. Always match your materials to the type of fabric you are working with, whether it’s cotton, polyester, or blends.

What printer settings should I adjust when using a DTF gangsheet builder?

When using a DTF gangsheet builder, important printer settings to adjust include ink saturation, resolution, and maintenance of the print head. Calibrate the ink saturation to prevent smudging or faint prints, and conduct test prints to find the ideal resolution for quality output. Regular maintenance of the print head helps avoid clogs and ensures consistent ink flow during printing.

What post-processing techniques are essential after printing gang sheets?

Essential post-processing techniques after printing gang sheets include proper powdering of the prints while warm, effective curing with a heat press, and checking for misalignment or defects. Evenly sprinkle adhesive powder over the design to enhance adhesion before curing at the designated temperature for the materials used. These steps are critical to ensure that the transfers are durable and properly adhered to the fabric.

What common issues might arise when creating designs for a DTF gangsheet?

Common issues that might arise when creating designs for a DTF gangsheet include print misalignment, quality problems like fuzzy or faded designs, and clogged print heads. To mitigate these issues, regularly check the alignment of your designs, adjust ink saturation and resolution settings for clearer prints, and decrease idle time between prints to prevent clogs. Implementing these strategies will enhance your overall DTF printing process.

| Key Point | Details |

|---|---|

| Introduction | Resource for mastering DTF gangsheet building, ensuring less waste and higher quality. |

| What is a DTF Gangsheet? | A gang sheet maximizes film area, reducing cost per item and waste, ideal for custom apparel production. |

| Setting Up Your Files | Use vector software, appropriately size designs, utilize tight layout arrangements, and save in compatible formats. |

| Choosing the Right Materials | Select high-quality DTF films, compatible inks, and proper adhesive powder for best results. |

| Printer Settings | Adjust ink saturation, resolution settings, and keep print heads maintained for optimal output. |

| Post-Processing Techniques | Apply adhesive powder, cure properly, and check for defects post-printing for the best durability. |

| Common Troubleshooting Tips | Address misalignment, quality issues, and clogged print heads for smoother operations. |

Summary

DTF Gangsheet Builder is an essential tool for optimizing your Direct-to-Film printing experience. By understanding the nuances of design setup, material selection, printer settings, and thorough post-processing techniques, you can significantly improve the quality and efficiency of your printing projects. Mastering these elements not only reduces waste and costs but also ensures that your prints are vibrant and durable. Engaging with online communities for continuous learning can further enhance your skills in this evolving field. Happy printing!