DTF transfers, or Direct to Film transfers, revolutionize the landscape of custom apparel printing by offering a dynamic method for producing high-quality designs. This cutting-edge technique showcases vibrant colors and exceptional durability, captivating the attention of both amateur and professional printers alike. As the demand for personalized fashion continues to soar, understanding DTF printing tools and techniques becomes increasingly vital for success in this competitive industry. In this article, we will delve into the essential aspects of DTF heat transfers, including the tools required and the innovative techniques that can elevate your printing game. Get ready to embark on an exciting journey into the realm of DTF transfers and unlock the potential to transform your creative visions into stunning pieces of wearable art.

Exploring the realm of direct printing onto film is an exhilarating venture for anyone fascinated by custom fabric creations. Known informally as DTF, this technique merges advanced printing technology with the art of apparel customization. The emergence of DTF transfer methods has empowered many aspiring designers and entrepreneurs to develop unique designs that stand out in a crowded marketplace. By utilizing specialized heat transfers and cutting-edge printing tools, anyone can learn to harness these innovative methods to create bespoke garments that cater to individual tastes. As we dive deeper into DTF printing techniques, you’ll discover the myriad of possibilities that await in the world of custom apparel.

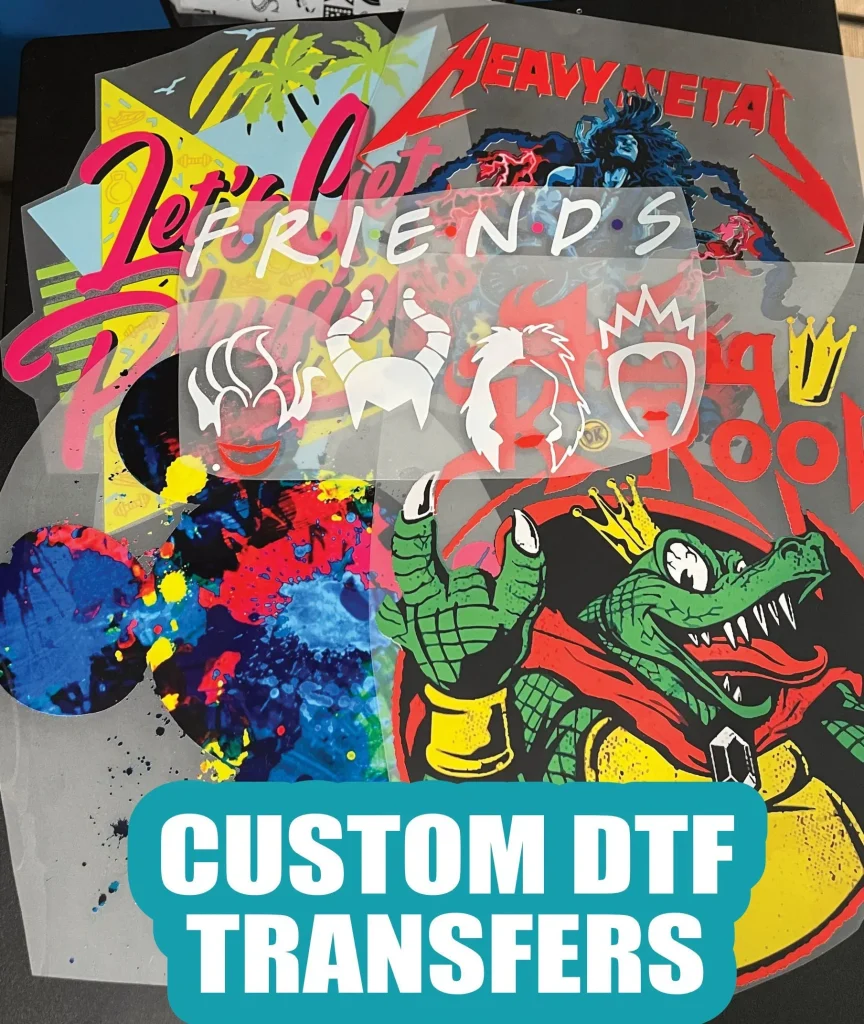

Overview of Direct to Film (DTF) Transfers

Direct to Film (DTF) Transfers is revolutionizing the custom apparel printing industry with its unique method of transferring designs onto garments. This process involves printing designs onto a special film, which can then be heat-pressed onto fabric. Unlike traditional heat transfer methods, DTF allows for intricate designs and vibrant colors while ensuring durability and wash resistance. As more businesses adapt DTF technology, it’s essential for beginners to understand its advantages and how it can elevate their printing capabilities.

The flexibility of DTF printing makes it an attractive option for both small businesses and established print shops. This method is compatible with various fabric types, including cotton, polyester, and blends, allowing for a wide range of apparel printing possibilities. Additionally, DTF transfers can produce detailed artworks with smooth gradients and vivid hues, enabling creators to cater to diverse customer preferences and trends in design.

Essential DTF Printing Tools for Beginners

For those venturing into DTF printing, equipping yourself with the right tools is crucial to your success. The primary instruments include a high-quality DTF printer capable of producing sharp, vibrant prints. Models from reputable brands, such as Epson and Brother, are widely recommended for their reliability and efficiency in producing excellent transfers.

Alongside a sturdy DTF printer, you will need a dependable heat press that can evenly distribute heat and pressure during transfer application. Furthermore, investing in quality DTF transfer films and adhesive powders will greatly enhance the durability and vibrancy of your designs. These components are key to achieving professional results in your custom apparel projects.

Art software like Adobe Illustrator or CorelDRAW is also vital, as it allows beginners to design eye-catching graphics. Mastery of these tools will not only speed up the design process but also refine the quality of the artwork you produce for your DTF transfers.

Best Practices for Effective DTF Transfers

To achieve optimal results with DTF transfers, implementing best practices is essential. Begin with setting your printer to the appropriate resolution and color profiles, as high-quality prints depend greatly on these configurations. Using the correct settings ensures that the colors are vibrant and details are crisp, which is crucial for customer satisfaction.

Pre-pressing garments before applying DTF transfers can significantly improve adhesion and overall print quality. This preparatory step removes moisture and provides a clean, smooth surface for application. Following the manufacturer’s guidelines regarding heat and pressure settings is also vital, as this will ensure that your transfers are secure and resilient against wear and washing.

Innovations in DTF Printing Technology

Recent innovations in DTF printing technology have made it easier and more affordable for small businesses to enter the custom printing market. Companies like Insta Graphic Systems are continuously enhancing their product lines, introducing new DTF heat transfers that boast improved color vibrancy and print quality. These advancements make it possible for beginners to produce professional-grade products with relative ease.

Moreover, advancements in DTF printing tools, such as state-of-the-art printers and heat presses, are streamlining workflows and increasing productivity. Beginners who adopt these new technologies can expect greater efficiency and accuracy, ultimately leading to higher customer satisfaction and increased profit margins.

Experimenting with DTF Techniques for Customization

Experimentation is key to mastering DTF printing techniques and discovering unique ways to customize apparel. Beginners are encouraged to explore various fabric types and settings to understand how different materials interact with DTF transfers. Testing different combinations of heat and pressure will allow you to refine your technique, ultimately enhancing the quality of your prints.

Furthermore, experimentation extends beyond materials; it also involves playing with artwork styles, color palettes, and transfer sizes. By embracing this creative process, you can find distinct ways to cater to niche markets or specific customer requests, helping you stand out in a growing marketplace.

Conclusion: Embracing the Future of DTF Transfers

As the DTF transfer market expands, opportunities abound for beginners and experienced printmakers alike. With tools and techniques continually evolving, those who embrace the latest innovations will stand at the forefront of the custom apparel printing revolution. Companies like Sam’s DTF Transfers set the pace for quality and service, serving as a benchmark for those entering the industry.

With dedication and a willingness to learn, newcomers will discover endless possibilities in DTF printing. By applying the right practices, mastering the necessary tools, and exploring creative techniques, you can build a successful venture that leverages the growing demand for custom apparel. The journey into the world of DTF transfers is not only about learning but also about expressing creativity and innovating in a dynamic field.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct to Film transfers, involve printing designs onto a special film which is then heat transferred onto garments. This method allows for vibrant and long-lasting prints, making it an excellent choice for custom apparel printing. The DTF printing process includes printing, applying adhesive powder, and then using a heat press to transfer the design onto the fabric.

What tools are essential for effective DTF printing?

Key tools for successful DTF printing include a reliable DTF printer, heat press, DTF transfer film, adhesive powder, and graphic design software. These DTF printing tools are critical to ensure high-quality transfers and vibrant colors in your custom apparel projects.

What are the benefits of using DTF heat transfers over traditional printing methods?

DTF heat transfers offer several advantages over traditional methods, including a broader range of fabric compatibility, vibrant colors, and durability. The Direct to Film printing technique allows for detailed designs without needing screens, making it faster and more economical for custom apparel printing.

How do I choose the best DTF printing film for my projects?

When selecting DTF transfer film, opt for high-quality options that enhance color vibrancy and print durability. Look for films that are user-friendly, especially if you’re a beginner. Experiment with different brands to find the one that best suits your DTF transfer techniques.

What common mistakes should I avoid when starting with DTF transfers?

Common pitfalls when starting with DTF transfers include incorrect heat settings, not pre-pressing garments, and using low-quality materials. Ensure you follow manufacturer guidelines for printing settings and care for your DTF prints properly to avoid issues with adhesion and durability.

How does the DTF printing technique compare with other custom printing methods like DTG or screen printing?

Unlike Direct to Garment (DTG) printing, DTF transfers can be used on a wider variety of fabrics and require less setup time. Compared to screen printing, DTF printing allows for more intricate designs without the need for multiple screens. This makes it ideal for small runs and detailed graphics in custom apparel printing.

| Key Components | Description |

|---|---|

| DTF Printer | Quality printers tailored for DTF printing, ensuring vibrant colors and high resolution, with notable brands being Epson and Brother. |

| Heat Press | Essential for transferring prints onto garments; look for adjustable temperature and pressure settings for best results. |

| DTF Transfer Film | High-quality films that enhance adhesion and print durability, some specially designed for improved color vibrancy. |

| Adhesive Powder | Applied to the design prior to heat pressing to bond ink to fabric; essential for effective DTF printing. |

| Artwork Software | Graphic design tools like Adobe Illustrator or CorelDRAW are essential for creating bespoke designs for transfers. |

Summary

DTF transfers provide an innovative and accessible way to dive into custom apparel printing. With the advancements in technology and tools available today, beginners can find success in creating vibrant, durable prints that stand out. Investing in essential equipment such as a DTF printer, heat press, and quality transfer film is crucial for ensuring high-quality results. By mastering the techniques associated with DTF printing, including pre-pressing garments and correct heating practices, you can enhance your output significantly. As the market continues to expand with influential players like Sam’s DTF Transfers and Insta Graphic Systems, the future of DTF transfers presents a world of opportunities for both hobbyists and aspiring entrepreneurs.