Successful DTF Transfers begin with understanding and applying essential techniques in the world of DTF printing. This innovative method allows for the transfer of stunning designs onto various fabric types, creating products that are not only visually appealing but also long-lasting. To make the most of DTF technology, printer enthusiasts must familiarize themselves with key DTF printing tips and best practices for DTF printing that can significantly enhance the transfer quality. From selecting high-quality materials to mastering DTF transfer techniques, each step plays a vital role in achieving outstanding results. Whether you are just starting or looking to improve your skills, this DTF printing guide will equip you with the knowledge needed for vibrant and durable prints.

The realm of DTF printing is gaining traction as a preferred choice for many designers and printers aiming to create professional-grade fabric prints. By utilizing advanced transfer strategies, individuals can effectively imprint exquisite designs directly onto textiles, which showcases both creativity and meticulous attention to detail. Aspiring printers should delve into various aspects of this printing method, such as how to DTF transfers and the importance of using top-notch supplies. When implementing these innovative techniques and adhering to industry best practices, the outcome can be truly transformative, allowing for a wide array of effects and applications. Throughout this discussion, we’ll explore critical insights to ensure your projects yield remarkable, high-quality results.

Essential Materials for Successful DTF Transfers

Using high-quality materials is crucial for successful DTF transfers. Opt for renowned brands that specialize in DTF films and inks. The right combination of materials not only influences the vibrancy of colors but also affects the durability of the prints on various fabrics. Ensuring that the films are compatible with your printer’s technology minimizes the risk of adhesion issues and promotes a seamless transfer process, leading to a professional finish.

In addition to DTF films and inks, the fabric itself plays a significant role in the success of your prints. Fabrics that are specifically designed for DTF transfers offer better results, as they enhance ink adhesion and color saturation. When selecting fabrics, always consider their material properties and how they interact with your chosen inks. This careful selection will help you achieve vibrant, high-quality prints that stand the test of time.

DTF Printing Tips for Optimal Results

To achieve optimal results with DTF printing, it is essential to implement specific tips that can enhance your overall output. One important tip is to regularly clean and maintain your printer. Clogged nozzles can lead to inconsistent ink flow, which affects the quality of the transfer. Regular maintenance, coupled with routine calibrations, ensures that your printer delivers the best performance possible.

Moreover, employing correct temperature and pressure settings during the transfer process is vital. Each DTF film may require different settings, so referring to the specifications provided by the manufacturer is crucial. By adhering to these guidelines, printers can avoid common pitfalls such as incomplete transfers and fading colors, thus ensuring vibrant, high-quality results.

Importance of Fabric Pretreatment for DTF Transfers

Pretreating fabrics is a key step in the DTF transfer process that should not be overlooked. Certain fabrics, especially synthetic ones like polyester, often have a lower affinity for inks, which can lead to issues with adhesion. By applying a pretreatment solution, you can significantly enhance the ink’s ability to bond to the fabric, resulting in clearer and more vibrant prints.

Additionally, the pretreatment process can vary based on the fabric type. It is important to test different pretreatment solutions to determine which best suits the fabrics you intend to use. This experimentation can yield higher quality results and improve the overall appearance and longevity of your DTF transfers.

Mastering DTF Transfer Techniques

To master DTF transfer techniques, it is essential to understand the nuances involved in the application process. The correct temperature range typically falls between 300°F and 330°F, with medium pressure applied evenly across the surface. Over-pressing can result in damage to the print, while under-pressing may lead to incomplete transfers. Fine-tuning these parameters according to the specific DTF film being used contributes to superior outcomes.

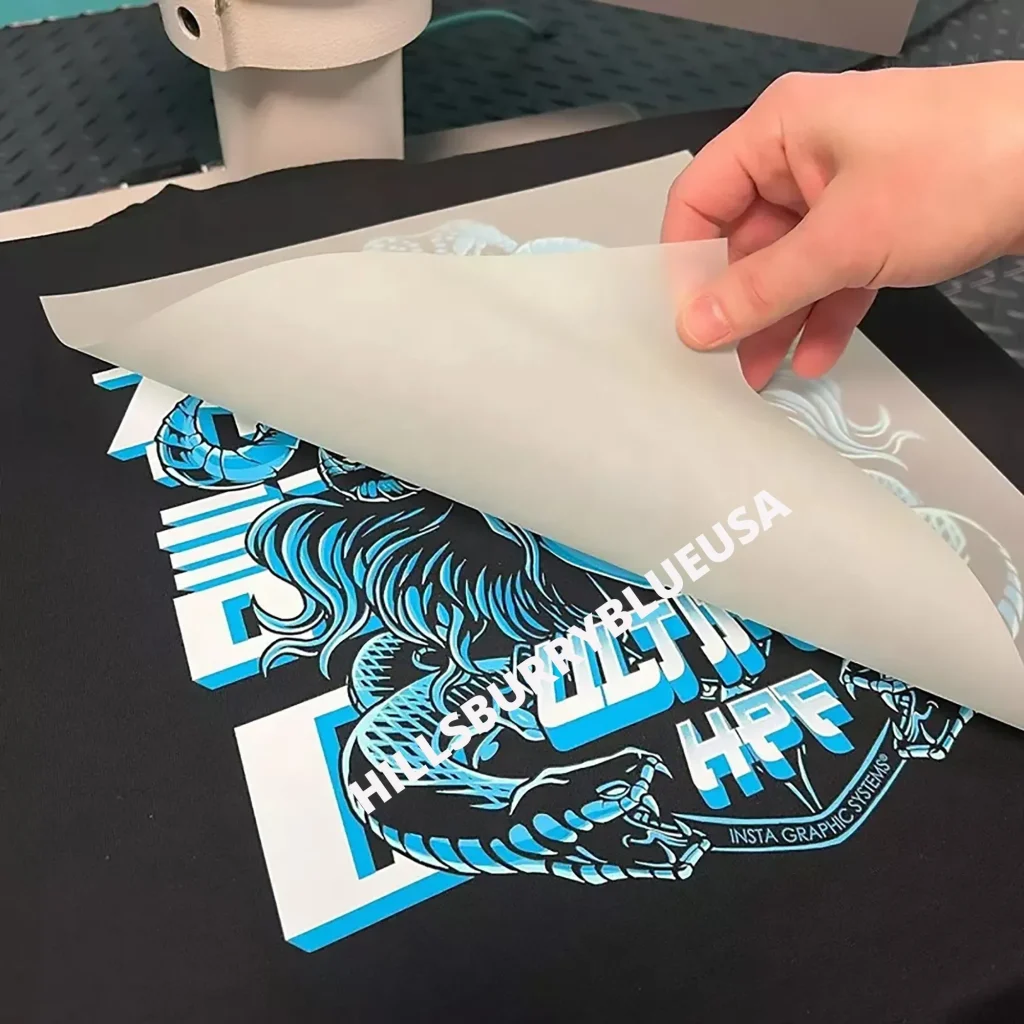

In addition to pressure and temperature, timing plays a crucial role in the success of DTF transfers. Adhering to the time specifications stipulated by manufacturers ensures optimal bonding of the ink to the fabric. Allowing adequate cooling time before removing the film can also prevent any potential sticking issues, thus preserving the integrity and appearance of the print.

Post-Transfer Care Best Practices

Proper post-transfer care is vital for ensuring the longevity of DTF prints. Once the transfer is complete, allowing sufficient cooling time is essential before peeling off the protective film. This step minimizes the risk of damaging the print and maintaining its vibrant colors. It is also recommended to wait 24 hours before the first wash to allow the ink to fully set.

When washing DTF printed fabrics, using cold water and gentle cycles is advisable to preserve the integrity of the print. Avoiding harsh detergents or bleach will further ensure that the colors remain bright and the quality of the print is maintained over time. Implementing these best practices will help extend the life of your DTF transfers, ensuring that they stay beautiful and intact.

Exploring New DTF Printing Techniques and Innovations

As DTF printing technology continues to evolve, staying informed about new techniques and innovations is essential for printers looking to enhance their skills. Exploring advancements such as improved inks and films can lead to better adhesion and color vibrancy. By staying updated, printers can adopt best practices that set them apart in an increasingly competitive industry.

Additionally, experimenting with different printing methods and fabrics can yield unique results that push the boundaries of traditional DTF transfers. By continuously testing and refining techniques, printers can develop their own signature styles, making their work stand out in the market. Embracing new technologies, while adhering to established best practices, creates a balanced approach to successful DTF printing.

Frequently Asked Questions

What are the best practices for successful DTF transfers?

Successful DTF transfers depend on several best practices. Firstly, always use high-quality DTF films and inks to ensure vibrant and durable prints. Regularly calibrate your printer to optimize settings for different films and fabrics. Additionally, pretreat fabrics to enhance ink adhesion, apply correct temperature and pressure during transfers, and provide proper post-transfer care to maintain print integrity.

How do I achieve successful DTF transfers?

To achieve successful DTF transfers, start by selecting quality materials such as reputable DTF films and inks. Ensure your printer is properly calibrated for the best results, and don’t forget to pretreat your fabrics. During the transfer process, adhere strictly to recommended temperature and pressure settings, and take care in the post-transfer phase by allowing the prints to cool and washing them correctly to preserve quality.

What techniques are essential for successful DTF printing?

Essential techniques for successful DTF printing include maintaining proper calibration of your printer, using high-quality inks and films, and pretreating your fabrics as necessary. During the transfer, ensure you apply the right temperature (300°F to 330°F), medium pressure, and follow the manufacturer’s timing guidelines. Lastly, practice good post-transfer care to keep your prints durable and vibrant.

What should I know about DTF printing tips for success?

Key DTF printing tips for success include using quality materials, keeping your printer calibrated, pretreating fabrics, applying the correct transfer techniques, and ensuring proper post-transfer care. Each step impacts the quality of your final print, so pay attention to details, such as temperature settings and fabric compatibility, for optimal results.

What are the critical factors for successful DTF transfers?

Critical factors for successful DTF transfers include the quality of materials (films and inks), printer calibration, and fabric preparation. Pretreatment for certain fabrics enhances adhesion, while meticulously following temperature and pressure guidelines during transfer ensures prints adhere correctly. Post-transfer care also plays a crucial role in maintaining print quality over time.

How can I improve my success rate with DTF transfer techniques?

To improve your success rate with DTF transfer techniques, focus on using high-quality inks and films, keep your printer well-calibrated, and ensure proper fabric pretreatment. Apply correct transfer settings (temperature, pressure, and time) consistently and maintain your prints through proper care after application. Regular testing on different fabrics may also help refine your approach.

| Tip | Key Point |

|---|---|

| 1. Use Quality Materials | Opt for high-quality DTF films and inks to enhance print quality and longevity. |

| 2. Keep Your Printer Calibrated | Regularly calibrate for optimal settings to prevent issues like ink bleeding. |

| 3. Pretreat Your Fabrics | Certain fabrics need pretreatment to enhance ink adhesion, especially synthetics. |

| 4. Apply Correct Techniques During Transfer | Monitor temperature, pressure, and timing during the heat transfer process. |

| 5. Post-Transfer Care is Key | Allow transfers to cool completely and follow proper washing instructions. |

Summary

Successful DTF Transfers hinge on mastering a few essential techniques that can elevate your printing game. By focusing on using high-quality materials, keeping your printer well-calibrated, pretreating your fabrics, applying correct heat transfer techniques, and maintaining proper post-transfer care, you can significantly enhance the quality and longevity of your prints. This method not only ensures vibrant and durable designs but also keeps you competitive in the printing world. As DTF printing continues to evolve, staying informed and practicing these tips will set you on the path towards greater success in your printing endeavors.