DTF printing, or Direct-to-Film printing, is revolutionizing the merchandise industry by offering high-quality, vibrant prints that can easily be customized. This innovative technique not only streamlines the printing process but also enhances the durability and attractiveness of products, making it a favorite among apparel brands. From t-shirts to accessories, DTF printing brings designs to life with unparalleled color depth and clarity. In this article, you’ll discover valuable merchandise printing tips that can elevate your products using DTF printing advantages. Whether you’re a designer or a retailer, learning about DTF design techniques can dramatically improve your approach to custom merchandise printing.

Direct-to-Film technology, often referred to as innovative transfer printing, has gained immense popularity due to its capacity to produce outstanding graphics with ease. This method simplifies the printing of detailed designs directly onto films, which can then be transferred onto a variety of fabric surfaces, making it adaptable for different merchandise. The flexibility of this approach enables businesses to cater to a diverse clientele, focusing on unique and personalized items. As companies search for effective merchandise printing solutions, embracing DTF as a contemporary printing method ensures capturing market trends and consumer preferences. With a thorough understanding of DTF printing benefits, brands can successfully navigate the evolving landscape of custom apparel production.

The Rise of DTF Printing in Merchandise

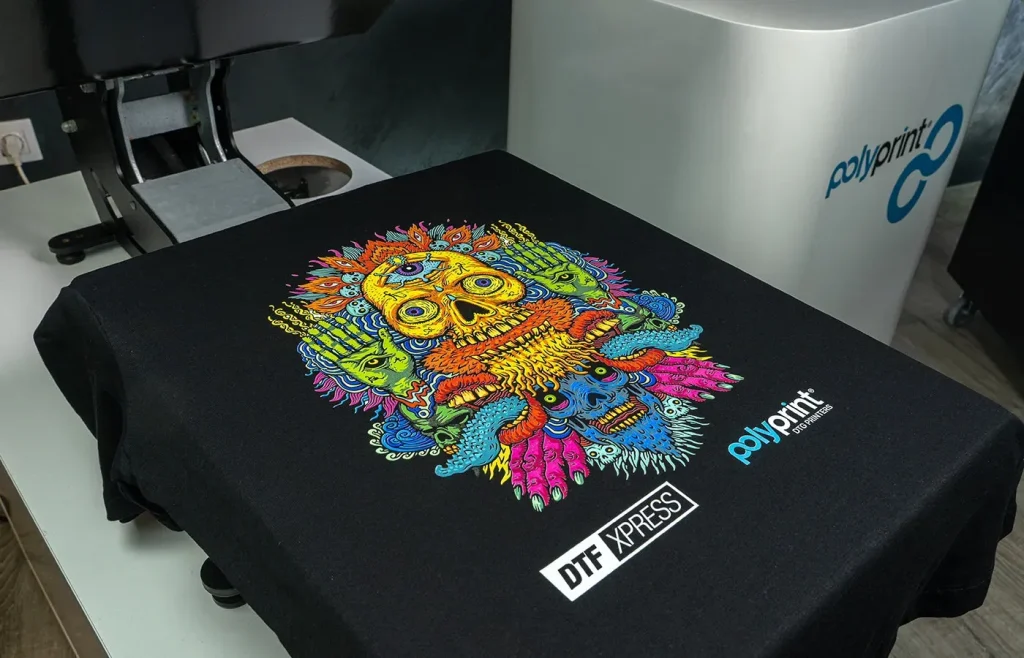

Direct-to-Film (DTF) printing has become increasingly popular in the merchandise industry, revolutionizing the way brands approach printing methods. This technology allows for high-quality graphics to be transferred directly onto various fabrics, creating vibrant and durable designs that resonate with consumers. As the market demands more customization, DTF printing stands out by offering the flexibility to produce small batches of unique merchandise quickly and efficiently. By minimizing setup times and reducing waste, businesses can adapt more swiftly to consumer trends and preferences.

The adaptability of DTF printing extends beyond its ease of use; it also encompasses the diverse range of materials it can print on. Whether it’s cotton, polyester, or blended fabrics, DTF technology provides reliable results that meet the varying needs of merchandise printing. As more businesses recognize the advantages of DTF, the demand for this method is expected to continue growing, paving the way for innovative merchandise possibilities.

Understanding the Advantages of DTF Printing

One of the key advantages of DTF printing is its efficiency and cost-effectiveness in production. Unlike traditional methods that may require multiple screens and extensive labor, DTF simplifies the process with just one transfer film. This not only reduces labor costs but also speeds up turnaround times, making it an ideal choice for businesses looking to stay competitive in the fast-paced market. Moreover, the ability to print intricate designs with fine details ensures that products stand out, satisfying customers who seek high-quality merchandise.

Additionally, DTF printing supports a wider color gamut, allowing for vibrant prints that appeal to a broader audience. Brands can create intricate designs with multiple colors without compromising on quality. This capability enables custom merchandise printing to reach new aesthetic heights and caters to consumer demands for personalization, thus enhancing brand loyalty. Overall, the advantages of DTF printing make it a compelling option for any business aiming to boost their merchandise game.

Tips for Successful Custom Merchandise Printing

To maximize the potential of DTF printing, businesses must focus on several key merchandise printing tips. Firstly, utilizing high-resolution images is crucial; prints should be at least 300 DPI to ensure sharp and vibrant output. Collaborating with skilled designers who understand the nuances of DTF design techniques can lead to eye-catching merchandise that differentiates the brand from competitors. This attention to detail in design not only elevates the product’s perceived value but also speaks to the brand’s commitment to quality.

Moreover, experimenting with different fabric types and colors can lead to exciting new products. DTF printing excels on both dark and light fabrics, making it versatile for various merchandise categories, from apparel to accessories. By testing new combinations and designs, businesses can stay ahead of market trends and meet the evolving demands of consumers, ensuring that their catalog remains fresh and relevant.

Essential Equipment for DTF Printing

Choosing the right equipment is fundamental to the success of DTF printing. High-performance printers specifically designed for Direct-to-Film processes, such as those from reputable brands like Epson and Mimaki, can significantly impact print quality and production efficiency. These modern printers provide advanced features that enhance usability and reliability, allowing even smaller businesses to produce professional-grade prints with relative ease.

Furthermore, investing in quality DTF inks is equally important. Superior inks not only enhance color vibrancy but also ensure better adhesion to fabrics, resulting in long-lasting prints that resist fading and washing. Businesses should consider partnerships with established ink suppliers to guarantee the best outcomes in their merchandise printing endeavors.

Mastering DTF Design Techniques

To achieve optimal results with DTF printing, mastering DTF design techniques is essential. This involves understanding how to create images that transition seamlessly onto fabric, which often includes using transparent backgrounds for light-colored garments. These design choices can alleviate common issues like ink bleed and ensure that the colors pop, capturing the attention of potential customers. Designers must also be encouraged to think innovatively, pushing the boundaries of what can be printed and allowing for creative collaborations.

In addition, utilizing software that caters to high-resolution graphics can significantly enhance the design process. Programs that specialize in vector graphics allow for infinite scaling of designs without losing quality. This is particularly beneficial when creating custom merchandise that requires unique dimensions and designs tailored to specific products. Emphasizing the importance of design in the DTF process can lead to higher satisfaction rates among customers and increased repeat purchases.

Emerging Market Trends in Custom Merchandise

As the demand for customizable merchandise surges, businesses must stay attuned to emerging market trends that highlight consumer preferences. Nowadays, personalization is a strong selling point, with customers actively seeking unique products that reflect their individuality. DTF printing is well-positioned to fulfill this need, offering a cost-effective method for producing high-quality, one-of-a-kind items that resonate with personal experiences and styles.

Moreover, sustainability is becoming a significant factor in purchasing decisions. Consumers are increasingly aware of the environmental impact of their choices and favor brands that adopt eco-friendly practices. DTF printing supports sustainability efforts by reducing waste through efficient printing methods and requiring fewer resources compared to traditional approaches. Embracing these trends not only positions businesses favorably in the market but also cultivates a loyal customer base that supports ethical practices.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a process that allows high-quality graphics to be transferred onto various surfaces, primarily textiles. This modern technique involves printing designs onto a special film, which is then heat-pressed onto the fabric, ensuring vibrant colors and durable prints that can withstand multiple washes.

What are the advantages of DTF printing over traditional methods?

DTF printing offers several advantages, such as better ink adhesion, versatility on dark and light fabrics, and the ability to create vivid images without requiring color profile adjustments. This method also reduces production time and costs, making it an ideal choice for businesses in the merchandise printing industry.

What equipment do I need for successful DTF printing?

To start DTF printing, you need a high-performance printer designed for this specific process, such as models from brands like Epson or Mimaki. Additionally, investing in quality DTF inks and heat presses is essential to ensure optimal print quality and durability of your merchandise.

How can I improve my DTF design techniques for better results?

Improving your DTF design techniques involves creating high-resolution images (300 DPI or higher), utilizing bold and colorful designs to take advantage of DTF’s color capabilities, and ensuring designs have transparent backgrounds for better results on lighter fabrics. Engaging creative designers can also enhance the differentiation of your merchandise.

What are some best practices for applying DTF prints?

For effective application of DTF prints, start with pre-pressing garments to remove moisture and wrinkles, use a heat press instead of an iron for consistent temperature and pressure, and always allow garments to cool post-transfer to ensure secure adhesion of the print.

How does DTF printing align with current market trends in custom merchandise?

DTF printing meets the growing consumer demand for customization and personalization in the merchandise market. As businesses strive to offer unique products, DTF printing’s cost-effectiveness and flexibility position it as a preferred method for creating personalized merchandise that attracts a wider customer base.

| Aspect | Key Points |

|---|---|

| What is DTF Printing? | A revolutionary printing technology that transfers high-quality graphics onto textiles, effective on both light and dark fabrics. |

| Advantages of DTF Printing | Versatile application, superior ink adhesion, cost-effective, and allows vibrant, durable designs. |

| Choosing Equipment | Investing in high-performance DTF printers (Epson, Mimaki) and quality inks is crucial for production and reliability. |

| Design Considerations | Focus on high-resolution images, bold designs, and transparent backgrounds for optimal results. |

| Application Techniques | Key techniques include pre-pressing garments, using a heat press, and allowing adequate cooling time post-transfer. |

| Market Trends | Growing demand for customizable merchandise; DTF printing is a cost-effective method for personalization. |

Summary

DTF printing is transforming the merchandise industry by offering a modern and versatile solution for high-quality printed products. This innovative technique enhances the customization potential for businesses, allowing them to meet and exceed customer expectations with vibrant and durable designs. By harnessing the power of DTF printing, brands can not only improve their product offerings but also ensure longevity and satisfaction, essential in today’s competitive market. With the right equipment, design considerations, and application techniques, businesses can take full advantage of what DTF printing has to offer.