DTF transfers, or Direct-to-Film transfers, are revolutionizing the custom apparel industry with their innovative printing technology. By utilizing a specialized film for design transfer, DTF printing achieves vibrant colors and intricate details that many traditional methods cannot match. As eco-friendly printing practices gain traction, businesses are increasingly adopting DTF for its ability to support sustainable production while delivering high-quality and personalized merchandise. This technology meets the rising demand for custom apparel, addressing contemporary apparel trends that emphasize uniqueness and individuality. With the potential to cater to diverse fabric types, it’s no wonder DTF transfers are quickly becoming the go-to choice for creative entrepreneurs and established brands alike.

Also known as Direct-to-Film prints, DTF transfers are emerging as a game-changer in the realm of personalized merchandise. This advanced printing method stands out by combining quality and versatility, enabling brands to craft highly detailed and colorful designs on a variety of fabrics. As the demand for custom apparel rises, especially among eco-conscious consumers, DTF technology presents a viable solution that aligns with sustainable practices. Additionally, the growing interest in innovative apparel trends highlights the importance of offering distinct items, making DTF an ideal option for businesses looking to stand out in a competitive market. Embracing this printing technique not only enhances product appeal but also resonates with consumers seeking unique, personalized experiences.

Understanding DTF Printing Technology

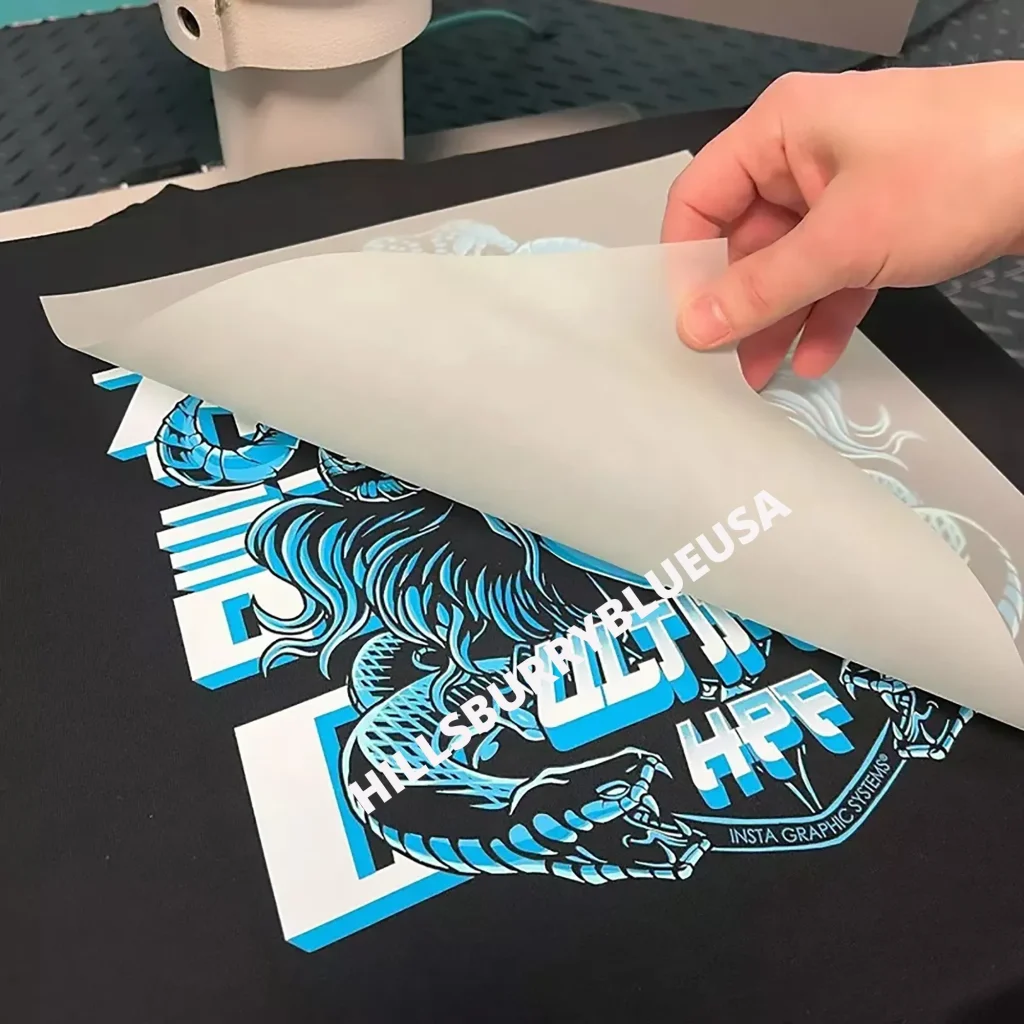

Direct-to-Film (DTF) printing technology has revolutionized the landscape of custom apparel, offering a new method that combines quality, versatility, and efficiency. Unlike traditional printing techniques, DTF involves printing designs onto a special film that then transfers to fabric using heat. This technology allows for vibrant colors and intricate designs that were previously unattainable with standard methods such as screen printing or heat transfer vinyl.

The modern DTF process is designed to cater to various fabric types, making it an exceptional choice for businesses that want to diversify their product lines. With the capability to print on cotton, polyester, and various blends, brands can easily create custom apparel that appeals to a broad customer base. Moreover, the rapid setup and production times enable companies to meet consumer demands without sacrificing quality or increasing costs.

The Rise of Personalized Merchandise

In a world where individuality is prized, personalized merchandise has become a dominant trend in the custom apparel market. The ability to create unique clothing pieces that express personal identity or celebrate special occasions has led to a surge in consumer interest. DTF transfers play a pivotal role in making this a reality, as they allow for quick changes in design and the creation of one-off pieces that cater to individual tastes.

From custom t-shirts for birthdays to clothing emblazoned with bespoke graphics for businesses, the versatility of DTF transfers ensures that brands can effectively capitalize on this desire for personalization. The technology allows for detailed graphics and text to be applied seamlessly, resulting in products that are not only visually appealing but also meaningful to the consumer. This increasing demand for personalized merchandise is set to drive growth in the custom apparel industry for years to come.

Advantages of DTF Transfers Over Traditional Methods

DTF transfers hold several advantages over traditional printing methods, making them an appealing choice for businesses in the custom apparel space. One major benefit is the ability to produce high-quality prints with an unlimited color palette without the extensive setup times typically associated with screen printing. This capability is essential in meeting the increasing demand for custom designs that are rich in color and detail.

Moreover, DTF printing technology enables businesses to be more agile in their operations. With the ability to quickly produce low quantities of customized items, brands can test new designs or respond to market trends without the risk of overproduction. This flexibility not only streamlines operations but also enhances the profitability of custom apparel lines, catering to both consumer trends and business needs.

Eco-Friendly Aspects of DTF Printing

As sustainability becomes a key focus in the apparel industry, eco-friendly printing methods have grown in importance. DTF printing technology aligns well with these environmental concerns, as it utilizes significantly less water and energy compared to traditional bulk printing methods. This reduction in resource consumption is crucial for businesses seeking to adopt greener practices while also appealing to eco-conscious consumers.

Additionally, many manufacturers are prioritizing the use of environmentally friendly inks and films in their DTF printing processes. This commitment to sustainability not only helps in reducing the overall carbon footprint of the production process but also positions brands favorably in the eyes of consumers who prioritize ethical production. By leveraging DTF transfers, companies can promote not just custom apparel but also a dedication to responsible manufacturing.

Technological Advancements Impacting DTF Transfers

Recent technological advancements have significantly enhanced the capabilities of DTF transfers, making them more accessible for both large businesses and independent creators. Compact and efficient printers now allow for high-speed production while maintaining exceptional print quality. These innovations have opened doors for small businesses that may have previously found digital printing technologies financially prohibitive.

Improvements in ink formulas and film types have also led to enhanced durability of DTF prints, ensuring that colors remain vibrant and designs withstand the test of time, even after repeated washes. This increase in quality not only enriches the customer experience but also fosters brand loyalty as consumers come to trust the durability of garments produced with DTF technology.

Emerging Trends in Custom Apparel

The landscape of custom apparel is rapidly changing, with DTF transfers at the forefront of these trends. The increasing popularity of online shopping has fueled the demand for customizable clothing options, as consumers seek unique items that reflect their personal style. As e-commerce continues to thrive, brands utilizing DTF technology can create tailored apparel that stands out in a crowded marketplace.

Furthermore, collaborations between brands and local artists or influencers are becoming commonplace, driving exclusive and limited-edition apparel lines. DTF printing allows these collaborations to flourish by enabling quick turnovers of design concepts and rapid production, ensuring that brands can capitalize on current trends while maintaining freshness in their offerings.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then applied to fabric using heat and pressure. This cutting-edge method allows for vibrant colors and intricate details, making it an ideal choice for custom apparel.

Why are DTF transfers gaining popularity in the personalized merchandise market?

DTF transfers are gaining popularity due to their high-quality output, versatility across various materials, and the ability to produce custom designs on demand. This is particularly appealing in the personalized merchandise market, where unique and tailored products are in high demand.

How do DTF transfers contribute to eco-friendly printing practices?

DTF transfers contribute to eco-friendly printing by using less water and energy compared to traditional methods. They also support on-demand production, reducing waste and overstock, which aligns with growing consumer preferences for sustainable apparel.

What advantages do DTF transfers offer compared to traditional printing methods?

DTF transfers offer several advantages over traditional printing methods such as screen printing, including unlimited color options, no extensive setup costs, and compatibility with a wide range of fabric types. This results in stunning custom apparel that maintains vibrancy over time.

What are the current trends in DTF printing technology for custom apparel?

Current trends in DTF printing technology include advancements in printer efficiency, improved ink formulations for better adherence and durability, and a rise in small businesses adopting this technique. These innovations position DTF transfers as a leading method for custom apparel production.

How can businesses leverage DTF transfers to enhance their custom apparel offerings?

Businesses can leverage DTF transfers by creating unique designs for limited-edition apparel, collaborating with local artists, and capitalizing on e-commerce platforms to offer personalized merchandise. This not only boosts brand visibility but also maximizes profits in a competitive market.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | Involves printing designs onto film that is transferred to fabric using heat and pressure, offering high-quality prints with vibrant colors. |

| Boost in Popularity | Demand for personalized apparel surged during the COVID-19 pandemic, leading to increased interest in DTF transfers among businesses and consumers. |

| Quality and Versatility | DTF transfers provide unlimited color options and are suitable for various materials, enhancing the overall appeal of clothing designs. |

| Sustainability Edge | Uses less water and energy compared to traditional methods and supports eco-friendly practices, appealing to environmentally conscious consumers. |

| Advancements in Technology | New DTF printer technologies offer businesses high-quality, fast prints, leading more companies to adopt this method. |

| Future Trends in Custom Apparel | DTF will likely dominate the personalized merchandise and small batch production segments, driven by consumer demand for unique products. |

| Market Growth and Opportunities | The custom apparel market is growing, creating unique opportunities for entrepreneurs to leverage DTF transfers for profit. |

Summary

DTF Transfers represent a groundbreaking advancement in the realm of custom apparel, demonstrating why they are set to dominate the industry. With their unique printing capabilities, businesses can produce stunning designs that appeal to a wide range of consumers. The integration of sustainable practices within DTF technology also aligns with the growing demand for eco-friendly products, making it an attractive choice for both brands and conscious consumers alike. As market growth continues, those who adopt DTF Transfers will ensure a competitive edge, solidifying their place in the future of custom apparel.