DTF Transfers, or Direct-to-Film printing, represent a groundbreaking shift in the printing industry, gaining momentum for their remarkable versatility and quality. Unlike traditional methods such as screen printing, DTF printing utilizes a film to create vibrant designs that can be heat-pressed onto various fabrics, ensuring durability and detail. The advantages of DTF printing are compelling, including lower setup costs which enable smaller businesses to compete in the marketplace without hefty investments. Furthermore, the industry is recognizing the importance of sustainable printing technology, making DTF transfers an eco-friendly choice that appeals to environmentally-conscious consumers. With a projected growth rate nearing 20%, DTF transfers are not just a trend; they are paving the way for the future of cost-effective and efficient printing solutions.

The rise of Direct-to-Film applications signifies an exciting evolution in print technology, as it fundamentally alters how designs are transferred onto clothing and other materials. Often regarded as a game-changer, DTF processes allow for intricate graphics to be reproduced with stunning accuracy, catering to a wide array of textiles from cotton to synthetic blends. This innovation is not just about enhanced output; it also facilitates a more affordable entry point for new businesses seeking to make their mark without breaking the bank. Additionally, the shift towards eco-conscious production practices underpins a broader trend of sustainability in printing. As demand grows for custom, personalized merchandise, DTF methods remain at the forefront, illustrating the industry’s move toward more efficient and environmentally friendly solutions.

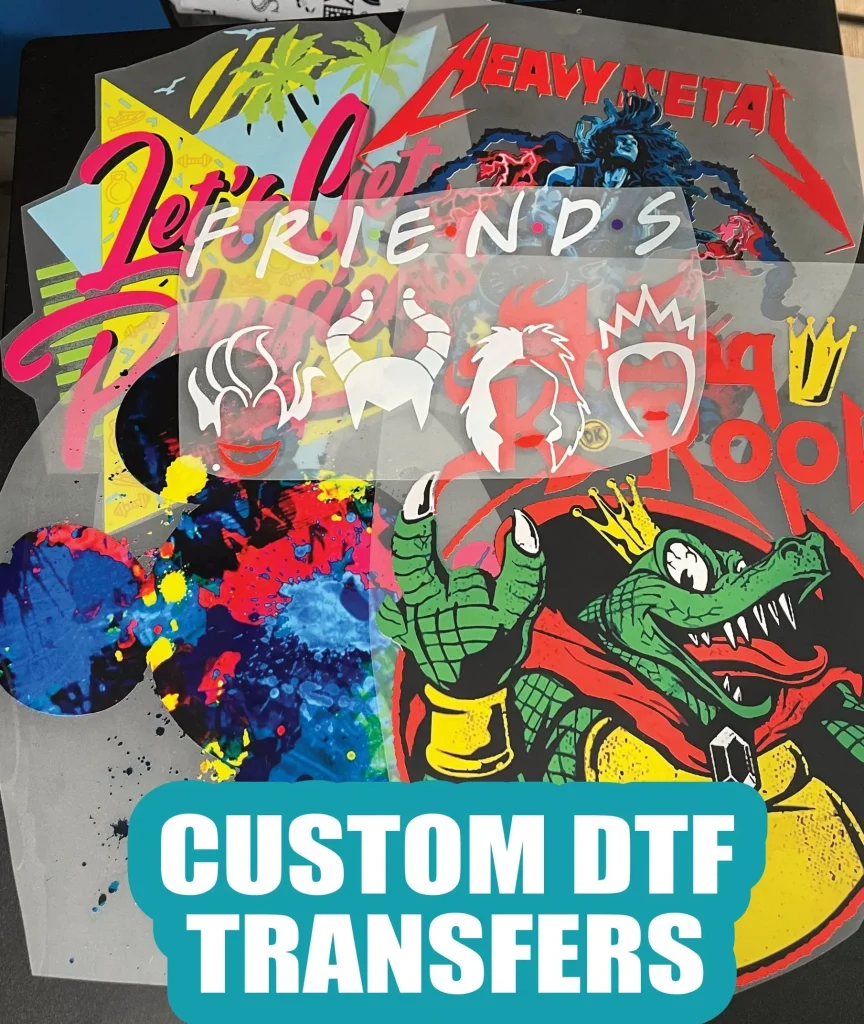

Understanding Direct-to-Film (DTF) Printing

Direct-to-Film (DTF) printing represents a groundbreaking shift in the printing industry, particularly for textile applications. This innovative process allows for the transfer of vibrant and complex designs onto garments using a specialized film. Unlike traditional screen printing, DTF printing bypasses the need for screens and lengthy setup times, resulting in a more efficient workflow that appeals to businesses of all sizes. By applying heat to transfer the print from the film directly to the fabric, DTF ensures a strong bond and durability that stands the test of time.

Furthermore, DTF printing is versatile, as it can adhere to various fabric types, including cotton, polyester, and their blends. This flexibility opens up a realm of possibilities for custom apparel, promotional items, and merchandise. As companies strive for unique and high-quality products, DTF printing rises to the occasion, offering exceptional color fidelity and detail that meets consumer demand for personalized and premium offerings.

Advantages of DTF Transfers Over Traditional Methods

The advantages of DTF transfers over older printing methods are significant and compelling. One of the most notable benefits is the quality of the finished product. DTF printing produces sharp, vivid designs that maintain their brilliance even after multiple washes. Unlike traditional screen printing, where colors can fade or blur, DTF technology preserves intricate details and ensures longevity for the printed graphics. This high level of quality positions DTF transfers as a preferred choice for brands aiming to create standout products.

In addition to unparalleled print quality, DTF transfers also offer considerable cost-effective printing solutions. The lower setup costs involved in using DTF printing mean that smaller businesses can access premium printing services without straining their budgets. Whether for limited runs or full-scale production, DTF printing enables companies to take on projects of varying sizes while keeping expenses manageable. This democratization of access empowers budding entrepreneurs and allows for greater innovation across the industry.

Sustainable and Eco-Friendly Printing Solutions

Sustainability is becoming increasingly crucial in today’s printing landscape, and DTF transfers contribute positively to this pressing issue. Eco-friendly practices integrated into DTF printing technology, such as the use of water-based inks and reduced energy consumption during production, help to minimize the environmental impact. As consumers increasingly prioritize sustainability, businesses adopting DTF methods are better positioned to meet this demand, appealing to environmentally conscious customers.

Moreover, DTF printing practices often result in less waste compared to traditional printing methods. The precision of ink application and the ability to print directly onto a variety of substrates reduce the amount of leftover material and ink used in the process. This focus on sustainability not only benefits the planet but also enhances brand loyalty among consumers who value responsible manufacturing practices.

Market Trends and Future Growth of DTF Printing

The market for DTF printing is anticipated to see robust growth, projected to expand at a rate of nearly 20% annually over the next few years. This growth is primarily driven by an increasing demand for customized apparel and merchandise among consumers who seek personalized experiences. The scalability of DTF technology allows businesses to respond swiftly to market trends, meaning they can cater to specific consumer needs while maintaining high production quality.

As more and more companies begin to integrate DTF printing into their operations, a noticeable shift in market dynamics is projected. Larger, established printing businesses are now incorporating DTF capabilities to keep pace with the competition, responding to heightened consumer expectations for rapid fulfillment and unique offerings. This transformative trend signals that DTF printing is not just a passing fad but a strategic move for companies wanting to thrive in an evolving marketplace.

User-Friendly DTF Technology for All Skill Levels

The advancements in DTF printing technology have revolutionized accessibility in the garment printing sector. Modern machines are designed with user-friendly interfaces that simplify the printing process, allowing individuals with minimal technical backgrounds to operate them efficiently. This ease of use opens the door for many aspiring entrepreneurs to enter the marketplace without the need for extensive training or experience, thereby enriching the industry with fresh ideas and creativity.

Additionally, the streamlined production processes associated with DTF printing lead to faster turnaround times. Businesses can fulfill orders more rapidly, aligning their operations with consumers’ demands for speedy service. In this climate of immediacy, user-friendly DTF technology not only enhances productivity but also significantly impacts customer satisfaction, creating a positive feedback loop that encourages repeat business.

Conclusion: Embracing the Future with DTF Transfers

As we look towards the future of printing, DTF transfers are poised to lead the charge, combining quality, affordability, and sustainability. Companies that adopt DTF technology position themselves for success in an increasingly competitive landscape, where consumer preferences are constantly evolving. The ability to produce high-quality prints quickly and cost-effectively offers a distinct advantage that many businesses are eager to capitalize on.

In conclusion, the shift towards DTF printing signifies a pivotal moment in the printing industry, one that embraces innovation while catering to the changing needs of consumers and the environment. Those who are willing to adapt and leverage the many benefits of DTF transfers will likely find themselves not only surviving but thriving in this new era of printing.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, are a modern printing technology where images are printed onto a special film and then heat-pressed onto fabrics. This process allows for vibrant, high-quality prints that adhere well to a variety of materials, making them ideal for clothing and merchandise.

What are the advantages of using DTF printing?

The advantages of DTF printing include high color fidelity, versatility in application to different fabrics like cotton and polyester, and lower setup costs compared to traditional methods. This makes DTF Transfers a cost-effective printing solution for businesses of all sizes, allowing even small startups to compete effectively.

Is DTF printing a sustainable printing technology?

Yes, DTF printing is regarded as a sustainable printing technology. Many DTF processes utilize eco-friendly inks and practices, reducing waste and energy consumption. As environmental concerns grow, DTF Transfers are becoming a popular choice for businesses looking to implement more eco-conscious printing solutions.

How does DTF Transfers compare to traditional printing methods?

DTF Transfers offer various advantages over traditional printing methods such as screen printing and direct-to-garment printing. They provide better color accuracy, lower initial setup costs, and the ability to print on diverse fabric types, making DTF printing a flexible and efficient choice for custom garment production.

What is the future of DTF printing in the garment industry?

The future of DTF printing looks promising, with the market expected to grow significantly. Industry projections estimate a compound annual growth rate (CAGR) of nearly 20%, driven by increased demand for personalized apparel and sustainable printing technology. DTF Transfers will likely continue to lead innovation in the printing sector.

Can beginners easily learn to use DTF printing technology?

Absolutely! DTF printing technology is designed to be user-friendly, making it accessible for those with little technical experience. Modern DTF printers and software simplify the production process, allowing beginners to create high-quality prints quickly and efficiently, aligning with today’s demand for rapid turnaround times.

| Key Point | Description |

|---|---|

| Overview of DTF Transfers | DTF printing is an innovative method for high-quality, durable prints on various fabrics. |

| Quality and Versatility | Produces intricate designs with high color fidelity on multiple materials. |

| Lower Setup Costs | More accessible than traditional methods, allowing small businesses to compete. |

| Eco-Friendly Practices | Uses eco-friendly inks and processes to minimize waste. |

| Market Growth | Projected CAGR of nearly 20% driven by demand for custom merchandise. |

| User-Friendly Technologies | Advances make DTF printing accessible and efficient for all users. |

| Industry Response and Trends | Larger companies are adopting DTF to remain competitive and responsive. |

Summary

DTF transfers are taking over the market as a leading technology in garment printing due to their excellent combination of quality, cost-effectiveness, and sustainability. This innovative printing method allows for the production of high-quality, vibrant prints on diverse fabrics, making it an ideal choice for businesses looking to expand their reach. With lower setup costs, user-friendly technology, and eco-friendly practices, DTF printing not only opens up opportunities for startups but also addresses the growing consumer demand for sustainable products. As DTF transfers continue to gain traction, businesses that harness their potential will undoubtedly secure a competitive edge in the evolving landscape of the printing industry.