Understanding UV DTF film quality is essential for any printer, shop owner, or brand that relies on direct-to-film transfers, as it shapes how the substrate, coating, adhesive, and curing work together to produce vivid colors, crisp details, and durable prints across batches. The overall performance hinges on how well the film base thickness, coating integrity, and adhesive formulation interact during transfer and curing, influencing color fidelity, edge definition, and wash durability. A rigorous DTF film quality comparison helps separate subtle differences between UV curing DTF film options and non-UV variants, revealing how coatings manage white ink opacity, color stability under light exposure, and the risk of curling or delamination. To keep results consistent, look for tests and datasheets that address caliper, surface energy, coating wear resistance, release liner compatibility, and laminating compatibility, along with practical notes on compatibility with your printer, inks, RIP workflow, and production schedule. With this information, you can choose a film that meets your design goals and production constraints while delivering reliable, color-accurate transfers that withstand washing, abrasion, and repeated heat pressing.

From a practical standpoint, think of a UV-activated transfer film as a substrate coated to receive inks, bonded with an adhesive, and cured under ultraviolet light to lock in color and durability. Related terms include UV-irradiated carrier sheet, photo-reactive coating, and heat-assisted transfer media, all describing a similar class of products used for decorating textiles and other substrates. Evaluators typically compare performance via color accuracy, gloss, adhesion, wash resistance, and image stability under light exposure to ensure consistency across runs. The aim is to match media choice with printer capabilities, substrate type, and production volume so results stay stable from batch to batch and over the garment lifecycle.

Understanding UV DTF Film Quality: Key Factors and Impacts

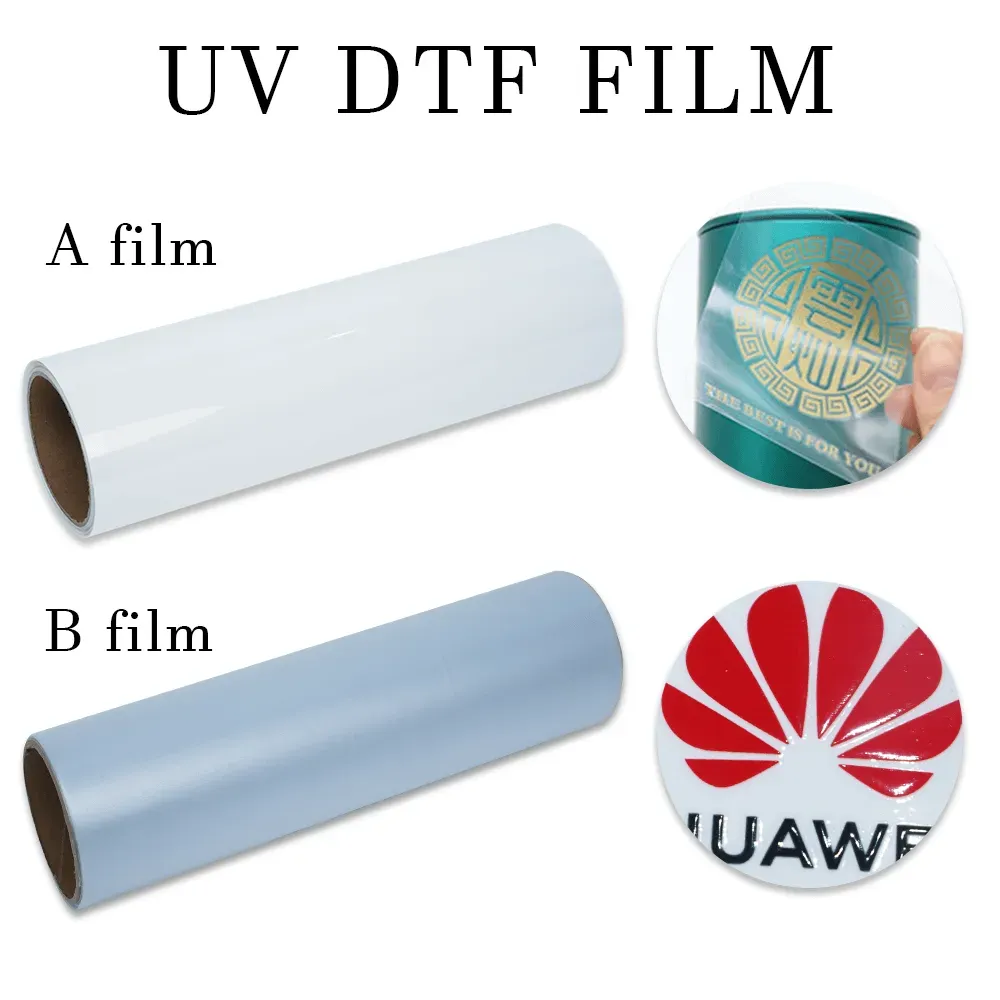

UV DTF film quality is an integrated measure that reflects how the film’s substrate, coating, adhesive, and curing interact to produce bright colors, sharp details, and durable prints. When evaluating quality, look at the film base and thickness, coating formulation, adhesive performance, release liner stability, and optical properties such as gloss and opacity. For UV-curable films, the compatibility with your lamp or LED cure system is also a critical factor that determines how consistently you achieve full cure and color fidelity.

In real-world workflows, these factors do not act in isolation. A high-quality coating won’t matter if the base is too flexible and stretches during lamination, or if the adhesive bond fails after washing. Understanding how all these elements interplay helps you predict batch-to-batch consistency, processing reliability, and final print durability across fabrics and designs.

UV Curing DTF Film vs. Non-UV: Choosing the Right Cure Path

UV curing DTF film requires access to a UV light source with the correct wavelength and intensity. When cured properly, this type of film tends to set quickly, delivering strong color fidelity and improved wash durability. This can be a significant advantage for high-volume shops or brands that demand fast turnaround without sacrificing image quality.

Non-UV-curing films rely on traditional curing methods such as heat and pressure, which can result in different performance characteristics in cure speed, gloss, and color stability. Your choice should consider your printer and ink system, heat-press equipment, and whether your workflow can consistently reproduce reliable cures without compromising substrate compatibility or edge definition.

DTF Film Quality Comparison: How to Evaluate and Benchmark

DTF film quality comparison is a structured process that begins with reviewing technical datasheets to compare caliper, coating type, adhesive, curing requirements, and substrate recommendations. This foundation helps you plan side-by-side tests that reveal color accuracy, gradient smoothness, edge sharpness, and white ink performance across films.

Beyond datasheets, conduct adhesion and wash tests, assess batch consistency by running multiple repeats, and consider printer compatibility and RIP settings. A disciplined comparison saves time, reduces waste, and provides a clear justification when selecting a film for your typical substrates and design work.

DTF Printing Film Durability: Ensuring Long-Lasting Transfers

Durability in DTF printing film directly affects transfer life, customer satisfaction, and brand reputation. A high-quality UV DTF film should maintain color and detail over many wash cycles, resist yellowing or fading under typical lighting, and perform consistently across cotton, blends, and synthetics.

Durability also encompasses resistance to curling, cracking, edge lifting, and residue on platens during removal. Evaluating these aspects through simulated wear tests helps you predict performance in real-world use and informs choices about coatings, adhesives, and curing parameters that support long-term results.

How to Choose DTF Film: Practical Guidelines for Shops

Choosing the right DTF film involves practical criteria like printer and RIP compatibility, end-use fabric considerations, and color management planning. This is where the question of how to choose DTF film becomes central: select films that align with your printer model, ink chemistry, and color workflow to minimize the need for repeated re-profiling.

Also weigh batch consistency, supplier support, and total cost of ownership. A film with robust documentation, clear curing guidance, and reliable technical support tends to yield fewer adjustments and more predictable results, especially when handling varied fabrics and complex designs.

Maximizing UV DTF Film Quality: Tips, Testing, and Best Practices

Storage and handling are foundational: keep films in a cool, dry place, use liners properly, and avoid bending edges to prevent creasing. Calibrate your UV lamp or LED cure system for consistent power to avoid tacky surfaces or over-cure that can dull color. These practices align with the UV DTF film characteristics that influence how well colors reproduce and how durable the print becomes.

Regular maintenance and test prints are essential for staying in spec. Clean printer heads and platens to prevent ink deposition issues, and run small test batches when introducing new film to your workflow. This approach helps you catch curing variances, time-pressure mismatches, and substrate interactions before they affect customers.

Frequently Asked Questions

What factors define UV DTF film quality and how can a DTF film quality comparison help you choose the right film?

UV DTF film quality is driven by film base and thickness, coating formulation, adhesive, release liner, optical properties, and UV curing compatibility. A DTF film quality comparison helps by letting you compare caliper, coating types, curing needs, and substrate compatibility; review datasheets, run side-by-side tests, perform adhesion and wash durability checks, and look for consistent batch performance.

What is UV curing DTF film and how does UV DTF film quality differ from non-UV films?

UV curing DTF film uses a UV light source to cure the coating, delivering fast set, strong color fidelity, and improved wash durability when quality is high. Non-UV films rely on heat and pressure, which can affect cure speed, gloss, and color stability. To compare, examine curing uniformity, lamp wavelength and intensity, and edge definition in side-by-side tests.

How should you choose DTF film with regard to UV DTF film quality and the guidance in how to choose DTF film?

Choose based on printer compatibility, end-use fabrics, color management, batch consistency, and supplier support. For UV DTF film quality, ensure the coating, adhesive, and curing requirements align with your printer, inks, and substrates. Use datasheets, recommended workflows, and practical side-by-side tests as outlined in how to choose DTF film guidelines.

What factors drive DTF printing film durability in relation to UV DTF film quality?

Key durability factors include wash resistance, edge integrity, curling resistance, and adhesive performance on substrates. High-quality UV DTF film should resist color fading and delamination after washing, maintain dimensional stability under heat, and minimize residue on the garment or platen.

What are the UV DTF film characteristics to evaluate to judge UV DTF film quality?

Evaluate color reproduction, white ink performance, opacity, edge definition, ink adhesion, substrate adhesion, laminating compatibility, wash and abrasion resistance, dimensional stability, and UV stability. Strong UV DTF film characteristics lead to vibrant colors, crisp edges, durable prints, and reliable performance over time.

What tests should you run to compare UV DTF film quality and perform a DTF film quality comparison effectively?

Review technical datasheets; run side-by-side prints; conduct adhesion and wash tests; check batch-to-batch consistency; verify printer compatibility; and consult supplier notes and curing guidelines. This structured DTF film quality comparison helps identify the best film for your workflow.

| Key Point | Description |

|---|---|

| Film base and thickness | Substrate rigidity, caliper, and dimensional stability affect transfer consistency; a film too flexible may stretch during lamination, while a very thick film can hinder feed and curing. |

| Coating formulation | Surface coating affects ink adhesion, color reproduction, white ink opacity, and edge definition. High-quality coatings help vibrant colors and smooth gradients without bleeding. |

| Adhesive layer | Adhesive must bond to the garment or substrate, release cleanly during transfer, and resist washing without residue or color shifts. |

| Release liner | A clean, stable liner minimizes dust and handling issues; liner compatibility with coating impacts ease of use and performance. |

| Optical properties | Gloss, opacity, and reflectivity influence perceived color accuracy and detail in the final image. |

| UV curing compatibility | For UV DTF films, the film must cure consistently under your lamp or LED system; improper curing can cause sticking, poor durability, or color shifts. |

| UV curing DTF film vs. non-UV films | UV curing DTF film requires a UV light source with the correct wavelength and intensity; when cured properly, it yields rapid set, strong color fidelity, and improved wash durability. Non-UV films rely on heat/pressure and may differ in cure speed, gloss, and color stability. |

| Color reproduction | Accurate color matching, stable skin tones, and clean whites; smooth gradients without banding. |

| White ink performance | Whitest white opacity and coverage are critical for vibrant prints on dark fabrics; the film should support robust white ink laydown. |

| Opacity and translucency | Depending on design needs, you may require strong opacity or specific translucency for layered effects. |

| Edge definition | Clear, sharp edges without feathering or bleed demonstrate good coating consistency and adhesion. |

| Ink adhesion and durability | Ink must adhere well and survive handling, washing, and wear without cracking or peeling. |

| Adhesion to substrates | Adhesive should bond securely to a variety of fabrics and surfaces while releasing cleanly during transfer. |

| Laminating compatibility | The film should bond with heat-press laminates and not delaminate under heat or steam. |

| Wash and abrasion resistance | Durable transfers resist cracking, peeling, or color fade after multiple wash cycles. |

| Dimensional stability | The film should maintain its shape under heat and pressure to avoid misregistration or warping. |

| UV stability and colorfastness | For UV DTF films, the cured image should resist yellowing or fading when exposed to light over time. |

| Quality evaluation approach | Review technical datasheets, run side-by-side tests, perform adhesion and wash tests, assess batch consistency, printer compatibility, and supplier support. |

| Durability and long-term performance | Consistent color over many washes, minimal color shifts, stable performance across fabrics, and resistance to curling or edge lifting. |

| Choosing the right film | Printer compatibility, end-use fabrics, color management, batch reliability, cost vs value, supplier support, and safety considerations. |

| Practical tips | Store films properly, calibrate curing, maintain stable temperature/press settings, clean printer heads, and run test prints when introducing new films. |

| Common pitfalls | Over-inking, substrate variability, skipping cure calibration, and assuming all UV films are equal. |

Summary

UV DTF film quality defines how well transfers look and endure across fabrics. Choosing the right UV DTF film is a pivotal decision that affects image quality, durability, and customer satisfaction. By focusing on UV DTF film quality factors such as film base, coating, adhesion, and curing compatibility, you can make informed decisions, perform effective DTF film quality comparisons, and select a film that aligns with your printer, substrates, and design goals. Remember to consider the full spectrum of related keywords—DTF film quality comparison, UV curing DTF film, how to choose DTF film, DTF printing film durability, and UV DTF film characteristics—as you evaluate options and implement your workflow for consistent, high-quality transfers.