UV DTF transfers are redefining how designers bring vibrant graphics to fabrics. They combine the flexibility of DTF transfers on fabrics with the durability of durable UV transfers, producing graphics that stay bold through repeated wear. With crisp DTF prints on textiles and UV printed transfers on clothing, you can achieve smooth gradients, sharp edges, and reliable adhesion. Following DTF printing best practices—proper substrate prep, calibrated presses, and correct curing—ensures long-lasting results. For brands seeking fast, cost-effective decoration with excellent wash durability, UV DTF transfers provide a scalable solution.

Beyond the exact name, this technology is often described as UV-curable fabric decals or digital textile transfers. These terms highlight how UV-curing inks and heat-activated adhesives work to bind graphics to a wide range of textiles. Other related expressions include UV-activated transfers, fabric decals, and graphic transfer films, all pointing to similar workflows and end results. Using these LSI-aligned terms in your content helps search engines understand the topic while guiding readers to related techniques and best practices.

UV DTF Transfers: Achieving Crisp, Durable Prints on Fabrics

UV DTF transfers offer the best of both worlds: the sharp edges and color depth of UV-curable inks with the flexibility of printed textile graphics. When applied with care, they deliver durable UV transfers that resist washing and daily wear, while still feeling soft to the touch. Following established DTF printing best practices helps ensure consistent results across fabrics, substrates, and garment types.

This guide focuses on turning the potential of UV DTF transfers into repeatable outcomes. By treating the workflow as an integrated process—from substrate selection and surface preparation to precise transfer parameters and thoughtful post-care—you can consistently achieve crisp DTF prints on textiles that stand up to repeated laundering and daily use.

DTF Transfers on Fabrics: Choosing the Right Substrates for Longevity

Fabric choice is foundational for DTF transfers on fabrics. Natural fibers like cotton and cotton blends typically yield vibrant color and good elasticity, while blends containing polyester can work reliably with adjusted heat and pressing times. Understanding fabric properties helps you target durability and colorfastness from the start.

Testing swatches before committing to a full batch is essential. Avoid fabrics with high moisture content or heavy coatings that can hinder ink transfer or produce a raised print surface. A small sample run lets you gauge adhesion, texture, and edge definition before scaling up.

Pre-Press Conditioning for Consistent UV DTF Results

Pre-press conditioning eliminates variables that compromise adhesion and longevity. Begin with a clean, dry surface, removing dust and lint with a soft brush or lint roller. If your workflow includes pre-pressing, a brief warm-up helps stabilize the fabric and reduces sheen variation across the print area.

A light preliminary press with parchment paper can flatten wrinkles and ensure a uniform transfer area. The goal is consistent pressure and temperature across the entire print zone, preventing hot spots, glazing, or misregistration that could weaken durability over time.

Optimizing Ink, Film, and Color Profiles for Crisp DTF Prints on Textiles

Selecting inks and films formulated for heat transfer and UV-curing is critical for crisp DTF prints on textiles. Calibrate color profiles to the fabric type and viewing conditions, and run tests to verify edge definition, color density, and alignment. Proper ink chemistry and film choices lay the groundwork for durable, vibrant results.

A stable print setup minimizes misregistration and maintains color fidelity across multiple transfers. When you apply a well-tuned workflow to UV printed transfers on clothing, you’ll notice consistent texture, reduced edge bleed, and a durable finish that stays true wash after wash.

Transfer Parameters and Press Settings for Durable UV DTF Transfers

Durable UV DTF transfers hinge on precise press settings. A common starting point is a medium-to-high temperature around 320–340°F (160–171°C) with medium to firm pressure and a dwell time of 8–12 seconds, followed by a cool-down and optional protective finish. For delicate fabrics or lower melt-point materials, adjust to shorter times or lower temperatures to prevent scorching.

Always place a protective barrier, such as parchment or kraft paper, between the transfer and the press to avoid ghosting and edge imperfections. Tailor the parameters to the fabric and ink system, and document results to support ongoing optimization—this is where DTF printing best practices pay off in repeatability and long-term durability.

Post-Press Care and Protection: Extending Life of UV DTF Transfers

Post-press care is a critical, often overlooked, factor in durability. Let the print cool completely before handling and avoid aggressive friction on the print area for the first 24–48 hours. Wash garments inside-out in cold to warm water using mild detergents to preserve color fidelity and adhesion.

If compatible with your ink system, consider a protective topcoat or sealing layer to boost abrasion resistance and UV stability. Adherence to fabric care guidelines—avoiding extreme heat and harsh cleaners—helps maintain color brightness and texture, extending the life of durable UV transfers and crisp DTF prints on textiles.

Frequently Asked Questions

What are UV DTF transfers and how do they help achieve crisp DTF prints on textiles?

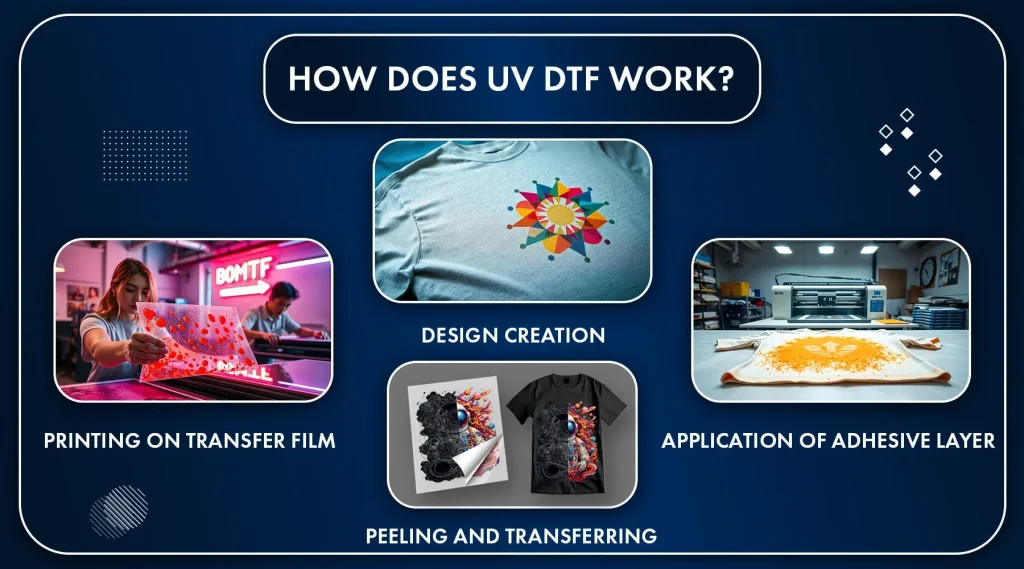

UV DTF transfers use UV-curable inks on a transfer film that is heat-pressed to fabric. The UV cure provides a quick, complete set, delivering sharp edges and vibrant color to achieve crisp DTF prints on textiles, while maintaining reliable adhesion through the fabric. This approach aligns with the goals of DTF transfers on fabrics for durable, high-quality results.

Which fabrics are best for UV DTF transfers to ensure durable UV transfers on clothing?

Natural fibers like cotton and cotton blends generally respond best for DTF transfers on fabrics, delivering strong color and flexibility. Polyester blends can work as well, with adjustments to heat and pressing time to maintain durable UV transfers. Always test a small swatch before full runs to confirm results for UV printed transfers on clothing.

What are the essential pre-press steps in DTF printing best practices for UV DTF transfers on fabrics?

Pre-press steps are a key part of DTF printing best practices: start with a clean, dry surface; remove lint; pre-press to flatten wrinkles and stabilize the fabric; use parchment paper to protect and ensure even pressure and temperature across the print area for durability.

What press settings are recommended for UV DTF transfers to produce crisp DTF prints on textiles?

Begin with around 320–340°F (160–171°C) at medium to firm pressure for 8–12 seconds, followed by a cool-down and optional protective finish. Adjust downward for delicate fabrics or shorter dwell times to prevent scorching, and always use a barrier like parchment to prevent ghosting and keep edges clean for crisp DTF prints on textiles.

How should I care for UV printed transfers on clothing to maximize durability and color retention?

Care for UV printed transfers on clothing by turning garments inside-out, washing in cold to warm water with a mild detergent, and avoiding bleach and fabric softeners. Air-dry or use low heat, and iron on the reverse side or with a protective sheet. Proper care helps sustain durable UV transfers and color fidelity over time.

What are common issues with UV DTF transfers and how can I troubleshoot to maintain crisp DTF prints on textiles?

Common issues include poor adhesion (revisit fabric choice and cure parameters), cracking or peeling (check cooling and avoid over-pressing), fading after washing (verify cure and consider a protective topcoat), edge bleed (tighten edge definition and ensure even pressure), and misregistration (confirm platen alignment and run test prints). Following DTF printing best practices helps prevent these issues and maintain crisp DTF prints on textiles.

| Key Point | Summary | Impact on UV DTF transfers |

|---|---|---|

| Definition | UV-curable inks yield sharp edges, rich color, and good wash durability with a soft hand and broad fabric compatibility. | Sets expectations for print quality and longevity. |

| Fundamentals | Prints rely on a heat-activated bond via transfer sheet and heat press; settings vary by fabric, ink, and film; surface prep and post-press care are critical. | Core workflow components that affect adhesion and lasting performance. |

| Fabrics | Cotton and cotton blends work well; polyester blends can work with adjusted heat/time; avoid high moisture or heavy coatings; test with swatches. | Fabric choice directly influences adhesion and color outcomes. |

| Pre-press | Start with a clean, dry surface; remove dust; pre-press warm-up; flatten wrinkles with parchment; maintain uniform pressure/temperature. | Pre-press quality prevents defects and improves durability. |

| Printing considerations | Use inks/films designed for heat transfer and UV-curing; calibrate color profiles; run tests; higher color density boosts vibrancy but may require longer cure or different pressure. | Color accuracy and edge crispness rely on proper ink/press calibration. |

| Transfer parameters | Typical: 320–340°F (160–171°C), medium–firm pressure, 8–12 seconds; cool-down and optional protective finish; adjust for delicate fabrics; use barrier sheet to prevent ghosting. | Precise settings drive adhesion and edge definition; tailoring to fabric reduces scorching. |

| Post-press care | Cool completely; wash inside-out; use cold-to-warm water and mild detergents; avoid fabric softeners; low-heat drying; consider a protective topcoat for longevity. | Post-care preserves color, adhesion, and finish over time. |

| Troubleshooting | Common issues: poor adhesion, cracking/peeling, fading, or edge bleed; fix by adjusting fabric selection, cleaning, cure, pressure, and alignment. | Offers practical fixes to prevent and resolve issues. |

| Durability comparison | UV DTF transfers typically offer durable, flexible results versus traditional screen printing or HTV when workflow is followed; color retention after multiple washes and good abrasion resistance are common. | Positions UV DTF as a strong option for small runs and prototyping. |

Summary

Conclusion: UV DTF transfers provide a robust pathway to high-quality, durable prints on fabrics when you respect the full workflow—from substrate selection and pre-press conditioning through precise transfer parameters and responsible post-care. By treating DTF transfers on fabrics as a connected process rather than a single step, designers and brands can consistently achieve crisp, vibrant results that hold up to washing, wearing, and daily use. Whether you’re decorating a small line of tees or prototyping a new textile print, applying these best practices will help maximize performance and appeal of your UV DTF transfers, delivering durable UV transfers and crisp DTF prints on textiles every time.