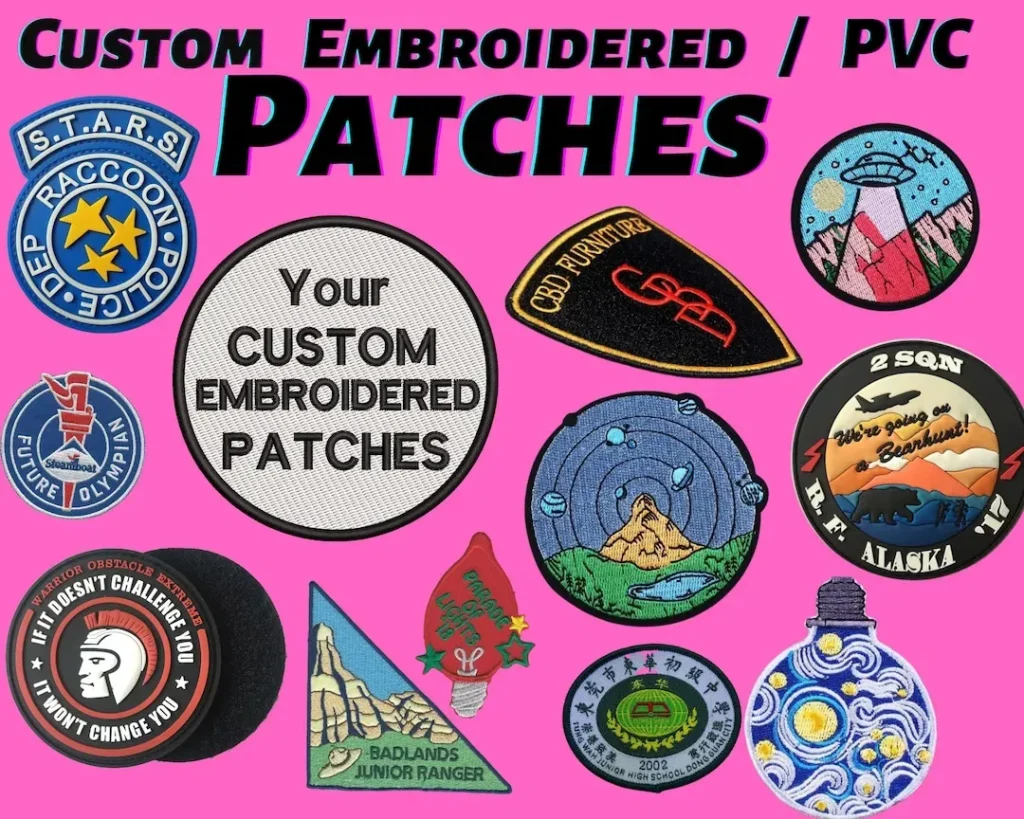

Custom embroidered patches have exploded from small accessories into powerful tools for personal expression and brand storytelling. They’re flexible, durable, and visually striking, making them ideal for upgrading a jacket, backpack, or bag. For those seeking inspiration, custom embroidered patches ideas can range from bold, high-contrast logos to playful, narrative motifs. This guide explores how patches for jackets, DIY embroidered patches, and patch design ideas work together to elevate clothing embellishments with patches across many surfaces. Read on to learn practical tips for sizing, backing options, and placement that help you tell a distinct story with every stitch.

Think of these items as fabric badges, embroidered emblems, or appliqués that carry meaning and style. LSI-friendly terms like embroidered insignias, garment patches, and wearable embellishments help search engines connect related ideas such as patch design ideas and clothing accents. With flexible backing and versatile placement, they unlock opportunities for personal expression across jackets, hats, bags, and more.

Custom embroidered patches: A versatile canvas for personal branding

Custom embroidered patches offer a flexible, durable, and highly visible way to express brand identity, personal history, or club affiliation. When you choose custom embroidered patches, you gain a reusable design language that can travel across jackets, hats, bags, and other accessories, turning ordinary fabrics into a cohesive story. For ideas, explore custom embroidered patches ideas that pair bold motifs with clean outlines to maximize legibility from afar while maintaining a tactile texture that prints can’t match.

Applied to jackets, hats, or bags, these patches act as portable branding or personal flair, enabling you to build a signature look across multiple items. Using clothing embellishments with patches can extend product lines, support limited editions, and encourage customers to collect or trade pieces, especially when backed by strong color stories and storytelling. Patches for jackets, in particular, benefit from bold placement and contrasting edges to ensure visibility even on busy fabrics.

Patch design ideas that make jackets pop and hats readable

Effective patch design ideas balance legibility, scale, and narrative. For patches for jackets, opt for bold shapes, high-contrast color palettes, and simple silhouettes that stay readable on denim or leather at a distance. Consider framing the focal image with a clean border and minimal internal detail to preserve clarity when scaled down.

Explore motifs that tell a story, from club emblems to travel-inspired symbols. Use color harmonies that align with the garment’s base tones, and plan backing and size early so the design fits on caps or sleeves without crowding. This thoughtful approach makes patches both collectible and versatile across outfits, aligning with broader ideas in patch design ideas and clothing embellishments with patches.

DIY embroidered patches: hands-on creativity and cost-efficient customization

DIY embroidered patches empower hobbyists and small businesses to prototype, iterate, and personalize with tangible control over every stitch. Whether experimenting with patch design ideas or testing colorways, DIY embroidered patches offer immediate feedback on how a motif reads on fabric and how backing choices perform during wear. This aligns with the broader trend of DIY embroidered patches and supports rapid, low-risk exploration.

With DIY, you can tailor patches for jackets, hats, and bags without minimums or long lead times. Start with a simple concept, then refine stitch density, satin stitch borders, and backing tension until the result feels durable and ready for everyday use. When you’re ready to scale, you can transition to professional patch production while carrying forward your DIY experiments as a blueprint for success.

Clothing embellishments with patches: color, texture, and durability

Clothing embellishments with patches add texture, dimension, and a tactile element that sets garments apart. The best designs combine dense satin stitches with open fill work to create contrast and movement while staying comfortable against skin and inside the garment. For jackets and bags, think about how patch density interacts with the fabric weave to avoid puckering.

Choose color palettes that reinforce the garment’s mood and audience. For durability, select high-quality threads and backing that withstand repeated washing. This approach makes patches durable fashion accents, useful for uniforms, clubs, or everyday wear, and it ties into the broader trend of using patches as a design language in clothing embellishments with patches and custom embroidered patches ideas.

Backing, application, and care to maximize patch longevity

Backing selection and proper application determine how long patches stay in place. Iron-on backs are quick for prototypes, sew-on backs offer the strongest attachment for frequent washing, and Velcro-backed patches provide quick reversibility for interchangeable looks. Each option affects how you plan patches for jackets, hats, and bags within a collection.

Care and maintenance extend patch life. Follow garment care instructions, avoid high heat, and inspect edges for fraying to re-sew or re-stabilize as needed. If you’ve used simple, legible designs and consistent color schemes, the patches remain readable and visually appealing wash after wash, turning your patch-focused project into a durable wardrobe staple.

Frequently Asked Questions

What are some custom embroidered patches ideas for jackets and other clothing?

Some custom embroidered patches ideas for jackets include a bold focal patch in high-contrast colors and a few smaller patches to tell a story. Choose shapes that stay legible from a distance and coordinate with fabrics like denim or leather. For patches on hats or bags, adapt the design to a smaller footprint and simpler outlines to maintain readability.

How do I apply patches for jackets to ensure longevity and easy maintenance?

Backing options—iron-on for quick customization on cotton blends, sew-on for the strongest hold, or Velcro for removable patches—affect installation and updates. To apply, preheat the fabric, position the patch, place a protective cloth, and press firmly for 15–30 seconds, then cool and test the adhesion. For longevity, sew around the edge or follow the backing manufacturer’s guidance and wash garment inside out on a gentle cycle to protect the patch.

What is the difference between DIY embroidered patches and professional patch production?

DIY embroidered patches are cost-effective for small runs and offer hands-on control over design and materials. Professional patch production provides consistent stitching, color accuracy, rapid turnaround, and a broader catalog of backing options, which is ideal for scaling. When considering custom embroidered patches ideas for a business, weigh tooling costs, minimums, and lead times against potential revenue and branding impact.

Which patch design ideas work best on hats or caps for custom embroidered patches?

For hats or caps, opt for patch design ideas that fit the curved front panel: simple shapes, bold outlines, and satin-fill embroidery for clear visibility from a distance. Keep focal patches compact (about 2–3 inches) and choose high-contrast colors to maximize legibility. Consider backing options like iron-on or sew-on to ensure a secure fit on headwear.

How can custom embroidered patches act as clothing embellishments with patches for branding or personal style?

Clothing embellishments with patches let you convey brand identity or personal style through cohesive layouts and color schemes. Plan a balanced arrangement across jackets, bags, and accessories, using a consistent color palette to reinforce recognition. A rotating patch lineup can boost engagement for clubs or brands by inviting customers to mix and match and tell new stories with each release.

| Topic | Key Points | Notes/Examples |

|---|---|---|

| Why custom patches matter |

|

Think of patches as a durable branding element that travels across jackets, bags, and accessories. |

| Patch design ideas and planning |

|

Consider narrative (club, team, milestone) to guide style and production. |

| Where to use Custom embroidered patches: jackets, hats, bags, and accessories |

|

Example usage guidelines by item type to maximize visibility and cohesion. |

| Backing options and application methods |

|

Follow manufacturer guidelines and consider item wash‑frequency when choosing backing. |

| Materials, color, and durability considerations |

|

Match patch material with garment fabric and plan for color consistency across product lines. |

| DIY embroidery vs. professional patch production |

|

Choose DIY for small runs or explorations; choose a professional partner for scalable programs. |

| Layout, sizing, and placement best practices |

|

Test layouts on mockups to ensure balance and readability. |

| Care, maintenance, and longevity |

|

Follow care labels; re‑application may be needed after heavy washing. |

| Sourcing and budgeting tips |

|

Budget planning should factor tooling, minimums, and lead times with expected revenue impact. |

| Inspiration and practical project ideas for everyday wear |

|

Use patches to build a narrative-driven collection that complements current fashion trends. |

Summary

Custom embroidered patches offer a versatile, durable, and visually compelling way to elevate jackets, hats, bags, and accessories. They transform plain garments into wearable storytelling canvases, conveying identity, values, and belonging through texture and color. When planning a patch program, consider design clarity, fabric compatibility, backing choice, placement, and care requirements to maximize longevity and impact. For hobbyists, clubs, or brands, patches deliver scalable branding that can be updated, rearranged, or refreshed to keep audiences engaged. Start imagining a small capsule of patches today and watch how custom embroidered patches turn everyday items into meaningful, durable fashion statements.