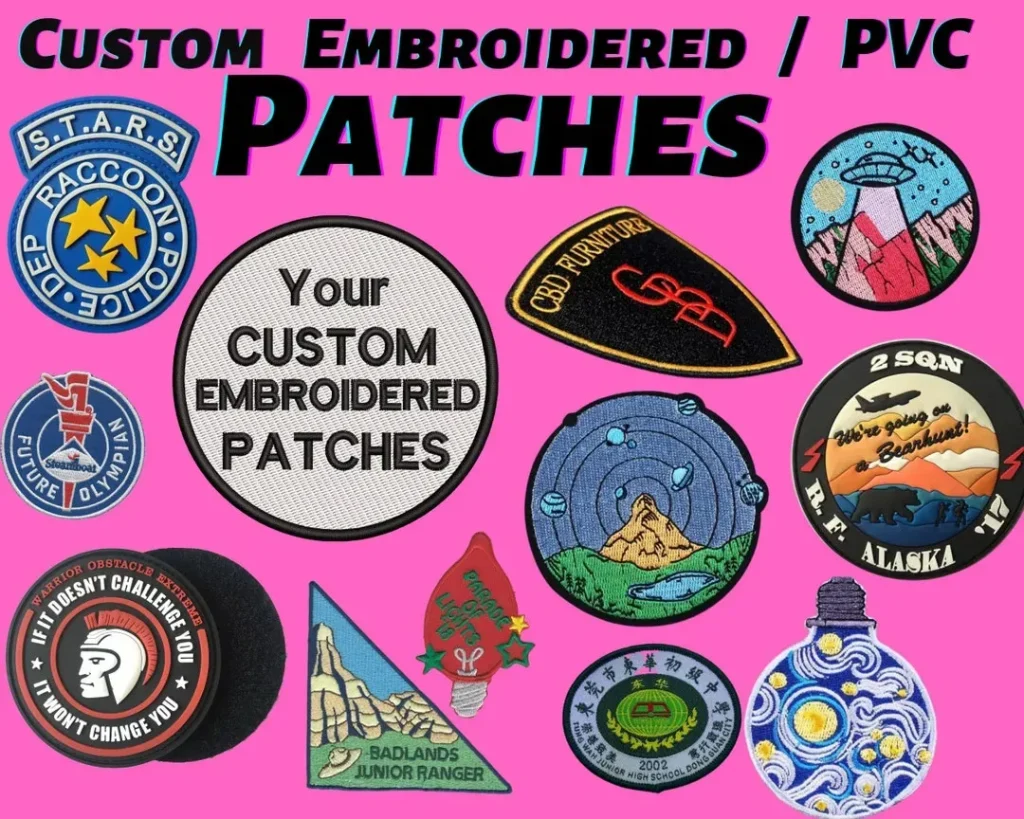

Custom embroidered patches are more than simple adornments; they function as durable branding tools. An effective embroidered patch design communicates identity at a glance and supports recognition across uniforms, merchandise, and events. The patch production process guides the journey from artwork to finished badge, ensuring color fidelity and durable construction. This approach strengthens brand consistency and customer loyalty by turning a garment into a portable message. Whether you favor sew-on patches or another attachment method, patches extend your logo into everyday wear.

Beyond simple naming, the concept translates to emblems, badges, and insignia that carry your brand into everyday life. As an SEO-friendly framing, this latent semantic approach connects ideas like branding with patches, patch design variations, and material choices into a cohesive narrative. For production realities, consider terms such as custom patch manufacturing and backing options that influence durability, care, and wear. Wearable branding becomes a storytelling tool that appears on uniforms, caps, bags, and event swag, building recognition across channels and moments.

Mastering Embroidered Patch Design for Brand Cohesion

Effective embroidered patch design starts with clarity and purpose. For brand cohesion, aim for bold silhouettes, clean borders, and high-contrast color choices that read instantly even at small sizes. When a patch communicates your logo at a glance, it becomes a portable billboard that reinforces recognition wherever your team travels.

Your design should align with brand guidelines across jackets, hats, bags, and event swag so every patch contributes to a consistent look. Consider classic shapes like rounds or shields, the Merrow edge for a clean finish, and strategic texture to convey depth without sacrificing legibility in production.

From Concept to Creation: The Patch Production Process

The patch production process begins with digitizing the artwork. A skilled digitizer maps out stitch types, density, color stops, and underlay stitches, translating a flat logo into a stitch-ready file.

After a proof is approved, a sample patch is produced to verify size, color fidelity, and texture before a full run. Color management relies on thread palettes from brands like Madeira, Mimaki, or RainBow to ensure consistent hues across lots, and choices about backing—iron-on, sew-on, or Velcro—shape how the patch will be applied and cared for.

Branding with Patches: Elevate Identity with Custom Embroidered Patches

Branding with patches extends your logo beyond screens and ads, turning apparel into mobile brand ambassadors. With custom embroidered patches, you can signal membership, achievement, or access in a tactile, durable format.

A cohesive patch program supports a uniform brand experience across lines, packaging, and promotions. When you design with branding with patches in mind, ensure the patch design and production standards align with your overall messaging so customers recognize your identity instantly.

Backing Options and Attachment Methods: Sew-On Patches in Focus

Sew-on patches offer durability and versatility on uniforms, outerwear, and gear used in active environments.

Backing options—iron-on for quick event application, Velcro for removable patches, or traditional sew-on—affect care, reusability, and garment compatibility. For rugged use, sew-on patches provide reliable hold through washes and wear.

Cost, Lead Times, and Custom Patch Manufacturing for Scale

Cost is driven by patch size, stitch count, backing type, shape complexity, and color variety. Lead times vary with order quantity and the complexity of the patch production, so plan ahead and request a pre-production sample for approval. In the realm of custom patch manufacturing, these factors matter for consistency and scalability.

Minimum order quantities (MOQs) and reordering potential influence forecasting and inventory planning. By partnering with a trusted supplier for custom patch manufacturing, brands can scale patches from pilots to full production while preserving color, detail, and durability.

Frequently Asked Questions

What are custom embroidered patches and how can they support branding with patches for teams and products?

Custom embroidered patches are durable fabric badges created with embroidery to display your logo or artwork. They act as scalable branding with patches, extending your brand to jackets, hats, bags, and event swag, while creating portable and recognizable brand touchpoints.

How does embroidered patch design influence the look and durability of your custom patch manufacturing?

Embroidered patch design requires clarity at small sizes, bold silhouettes, high contrast colors, and appropriate shape and border choices. These decisions affect color fidelity and stitch density in custom patch manufacturing, helping ensure the final patches look consistent across batches.

What is the patch production process for turning artwork into durable custom embroidered patches?

The process starts with digitizing the artwork, then proofing, creating a production sample, and finally full production. Color matching and backing selection are confirmed during sampling to ensure the patches meet branding standards.

Which backing options are best for sew-on patches when branding with patches?

Backing options include sew on, iron on, and Velcro. Sew on patches offer durability and long wear, iron on patches provide quick application, and Velcro backings allow removable patches. Border styles such as Merrow edges and satin borders influence edge finish.

How can I optimize cost lead times and order quantities when scaling branding with patches through custom patch manufacturing?

Plan early and define size, shape, and backing to control stitch counts and costs. Request a pre production sample to verify color and texture before a full run. Consider MOQs and ordering patterns to balance inventory and lead times.

| Key Point | Summary |

|---|---|

| Introduction | Custom embroidered patches are a versatile branding tool that elevate uniforms, merchandise, and ambassador programs; they act as a durable, portable wearable billboard that helps tell your brand story. |

| Value and Longevity | Patches provide longevity through sturdy backing and colorfast threads, extending your logo to jackets, hats, bags, and event swag while reinforcing recognition and belonging. |

| Scalability | A single patch design can be replicated across thousands of garments without losing fidelity, supporting consistency from prototypes to last-season merchandise. |

| Design Considerations | Prioritize clarity at small sizes with bold silhouettes, simple borders, and high-contrast colors. Key elements: shape, size, color, and border; consider outline styles like Merrow edges or satin borders; use texture sparingly for smaller patches. |

| Materials & Backing | Base fabrics include twill, felt, and cotton; backings include iron-on, Velcro, and sew-on. Choose backing based on wearer and care needs; each option has trade-offs for durability and replaceability. |

| Production Process & Color Management | Digitize artwork to define stitches, density, color stops, and underlay. Use thread palettes from Madeira, Mimaki, or Rainbow; perform proofs and color matching to ensure consistency across lots. |

| Border Styles | Outline options like Merrow edges provide a clean border and reduce fraying; satin stitch borders emphasize the edge for emphasis. |

| Production Tips | Follow a structured workflow: clear artwork and style guide; decide size/backing early; digitize and test with a small batch; approve a production-ready sample; implement quality control. |

| Branding & Strategy | Patches should align with your brand narrative, signal membership or achievement, and support merchandising. Ensure patch design reflects brand values and maintains consistency across product lines. |

| Cost, Lead Times & MOQs | Pricing depends on patch size, stitch count, backing, shape, and colors. Lead times vary by manufacturer and quantity; consider MOQs and plan ahead for demand. |

| Use Cases Across Industries | Patches fit sports, fashion, clubs, corporate events, and other contexts for membership, insignia, and promotional items, all benefiting from consistent design and manufacturing. |

| Maintenance & Care | Care guidance: minimize heat and abrasion; turn garments inside out for machine washing; avoid high heat drying; follow iron-on backing cautions to protect patches. |