Direct-to-Film Printing (DTF) is redefining garment decoration for 2025, opening new workflows for designers and print shops. As the ecosystem of DTF supplies expands, equipment, films, and inks empower vibrant transfers with less setup than traditional screen printing. Advanced printing techniques balance color density and texture, delivering a soft hand on a wide range of fabrics. In practice, print teams benefit from reliable printers, accurate color management, and simple post-processing. This guide helps you plan for quality DTF workflows, including reliable films and inks and scalable garment transfers.

Viewed through an alternative lens, this is a film-transfer workflow, sometimes called ink-on-film technology or printer-to-fabric transfer. The method uses a carrier film, a bonding powder, and heat to apply vibrant imagery to textiles, combining digital design with durable results. As a modern textile decoration option, it sits alongside other digital garment decoration approaches, emphasizing color fidelity, texture, and wash durability. In 2025, growing demand has pushed DTF printers 2025 models toward greater reliability, lower running costs, and broader material compatibility. Manufacturers and studios can optimize by selecting compatible films and inks, testing on common fabrics, and documenting best practices for consistent transfers.

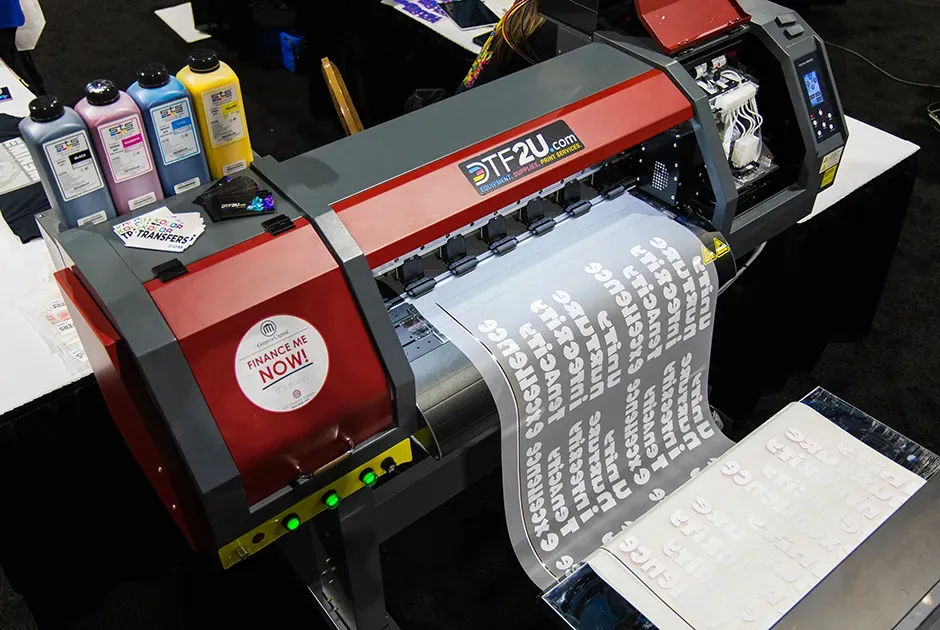

Direct-to-Film Printing (DTF): A Modern Overview for 2025

Direct-to-Film Printing (DTF) is redefining garment decoration in 2025, delivering a soft hand, vivid color, and durable transfers across a wide range of fabrics. As the DTF supplies ecosystem matures—films, inks, powders, and alignment tools—designers and print shops can achieve professional results with lower setup costs than traditional screen printing.

This approach relies on Direct-to-Film printing techniques that separate the film transfer step from the garment print, enabling better color density, sharper details, and easier workflow management. For both small studios and larger production houses, understanding DTF garment printing workflows helps you select the right DTF printers 2025 models, films, and inks to scale projects efficiently.

DTF Supplies and How to Build a Reliable Workflow

DTF supplies power a reliable workflow from design to finish. Start with the core categories—DTF printers, DTF films, and DTF inks—and plan for bonding powders, curing equipment, and routine maintenance to keep production moving.

When choosing DTF films and inks, look for compatibility with your printer, predictability of color, easy release from the sheet, and reliable bonding with the powder. Also consider coating compatibility, film thickness, and a workflow-friendly curing process to minimize setup time.

Choosing the Right DTF Printer in 2025

In 2025, the market offers a range of DTF printers 2025 with varying print heads, speeds, and ink sets (CMYK plus white). Critical considerations include print quality, uptime, support, and total cost of ownership.

Evaluate after-sales service, spare parts availability, and firmware updates, because a well-supported printer reduces downtime and helps maintain consistent results for DTF garment printing in busy periods.

DTF Films and Inks: Color, Compatibility, and Durability

A strong pairing of DTF films and inks yields vibrant transfers with sharp edges and robust wash durability. Choose film thickness and coating that align with your bonding powder and the fabrics you most often print on.

Test different ink sets for color density and white underbase performance, ensuring the white layer remains bright on dark garments. Proper synergy between DTF films and inks minimizes misregistration and color shifts across lots.

Techniques for High-Quality Direct-to-Film Printing (DTF)

Color management begins with a solid white underbase on dark fabrics and reliable ICC profiles to preserve brightness. Use proper halftone settings to maintain edge definition on fine lines.

Layering and texture can emerge from the powder as a design element; experiment with powder thickness and curing times to achieve the desired surface feel while keeping transfers flat and durable. Document an SOP to ensure repeatable results across batches and fabrics.

Embedding DTF into Your Business: Pricing, Turnaround, and Quality

Integrating DTF into your business means thoughtful pricing, fast turnaround, and quality assurance. Build pricing that covers material costs (DTF films and inks, bonding powders), equipment depreciation, maintenance, and energy use, with tiered options by fabric type.

Marketing and operations should highlight the advantages of DTF garment printing—color vibrancy, fabric versatility, and everyday care for customers. Consider eco-friendly inks and responsible waste management to appeal to sustainability-minded buyers and to support scalable growth.

Frequently Asked Questions

What is Direct-to-Film Printing (DTF) and how does it work?

Direct-to-Film Printing (DTF) is a coating-to-transfer process in which ink is deposited onto a PET film, then coated with a bonding powder and heat-transferred to fabric. This yields a soft hand, vivid color, and durable results across many fabrics. The workflow relies on reliable DTF supplies (films, inks, powders) and a well‑controlled heat transfer step to ensure consistent results.

What Direct-to-Film printing techniques can boost color density and detail?

Key Direct-to-Film printing techniques include planning a strong white underbase for dark fabrics, high-resolution printing, and precise halftone settings to preserve edge definition. Use color management with ICC profiles and adjust powder thickness to fine-tune texture and durability across different fabrics.

How should I evaluate DTF printers 2025 for a small shop?

When selecting DTF printers 2025 models, look for reliable print heads, support for CMYK plus white ink, fast yet accurate output, easy maintenance, and solid after-sales service. Consider total cost of ownership, ink yield, and vendor support to ensure a practical fit for a small shop.

What should I know about DTF films and inks for best transfers?

DTF films and inks should be chosen as a compatible pair designed to work together. Consider film thickness and coating compatibility with bonding powder, plus inks (water-based or pigmented) that deliver strong color, good opacity, and wash durability for long-lasting transfers.

What are the best practices for DTF garment printing to ensure durability?

Best practices include calibrating the heat press for consistent temperature and pressure, applying bonding powder evenly, and properly curing the film before transfer. Regular printer maintenance and testing on common fabrics help maintain transfer quality and durability.

What common issues occur in DTF garment printing and how can I troubleshoot them?

Common issues include fading colors after wash, white underbase inconsistencies, powder clumping, film not releasing cleanly, and color shifts between batches. Troubleshoot by verifying curing temperatures, adjusting white ink layering, ensuring fresh bonding powder, cleaning surfaces, and recalibrating ICC profiles and film/ink compatibility.

| Topic | Key Points |

|---|---|

| What Direct-to-Film Printing (DTF) is | Coating-to-transfer process: inkjet-like printer deposits ink on PET film, which is then coated with bonding powder and heat transferred to fabric. Result is a soft feel, vibrant color, and durable finish suitable for apparel and accessories. |

| How it differs from alternatives | DTF uses a separate film transfer step, often yielding better color density on a wider range of fabrics. Compared with traditional heat transfers, DTF can offer easier color adjustments, sharper details, and enhanced wash durability. |

| Why it’s popular in 2025 | The DTF supplies market has matured—films, inks, powders, and alignment tools are more reliable, printers are more affordable, and workflows are streamlined for higher throughput and lower labor costs. This makes Direct-to-Film printing a practical choice for small shops and larger production houses alike. |

| Choosing the Right DTF Equipment and Supplies | DTF printers: Look for machines with reliable head technology, good support for multiple ink types (CMYK plus white), and robust maintenance options. DTF films: sharp image quality, easy release, compatibility with your ink set; consider film thickness and coating compatibility with bonding powder. DTF inks: water-based or pigmented inks; bonding powders: fine, uniform powders; curing/heat transfer equipment: reliable heat press or conveyor dryer; post-processing and maintenance: cleaning kits and routines. |

| Direct-to-Film Printing: How the Process Works | Design and color management; printing onto the PET film; applying bonding powder; curing the film; transferring to fabric; finishing and care. |

| DTF Supplies in 2025: Best Practices | DTF films and inks synergy; powder quality and application; printer maintenance; heat press settings; fabrics and substrates; testing and documentation. |

| Techniques for High-Quality Direct-to-Film Printing (DTF) | Color management and white underbase; halftone and detail control; layering and texture with the powder; SOPs for consistent results; color consistency across fabrics. |

| Integrating DTF into Your Business or Studio | Pricing strategy; turnaround times; quality assurance; marketing and education; environmental considerations and responsible disposal. |

| Troubleshooting Common Direct-to-Film Printing (DTF) Issues | Fading colors after wash; white underbase inconsistencies; powder clumping or poor adhesion; film not releasing cleanly; color shifting between batches. Solutions involve curing parameters, ink compatibility, powder handling, and ICC profile recalibration. |

| The Future of Direct-to-Film Printing (DTF) in 2025 and Beyond | Expect improvements in printer reliability, diverse film formulations, and better integration with automated workflows. Faster curing, smarter color management tools, and more cost-effective options for small businesses. |

Summary

Direct-to-Film Printing (DTF) represents a flexible, durable, and scalable approach to modern garment decoration. With a growing lineup of DTF printers 2025 models, improved DTF films and inks, and dependable bonding powders, you can build a robust workflow that delivers vibrant results on a wide range of fabrics. By planning thoughtfully, investing in quality DTF supplies, and refining your techniques, you’ll be well-positioned to meet customer demand and stand out in a competitive market. Whether you’re creating custom apparel, accessories, or home decor, Direct-to-Film printing offers a compelling blend of quality, efficiency, and versatility for this year and beyond.