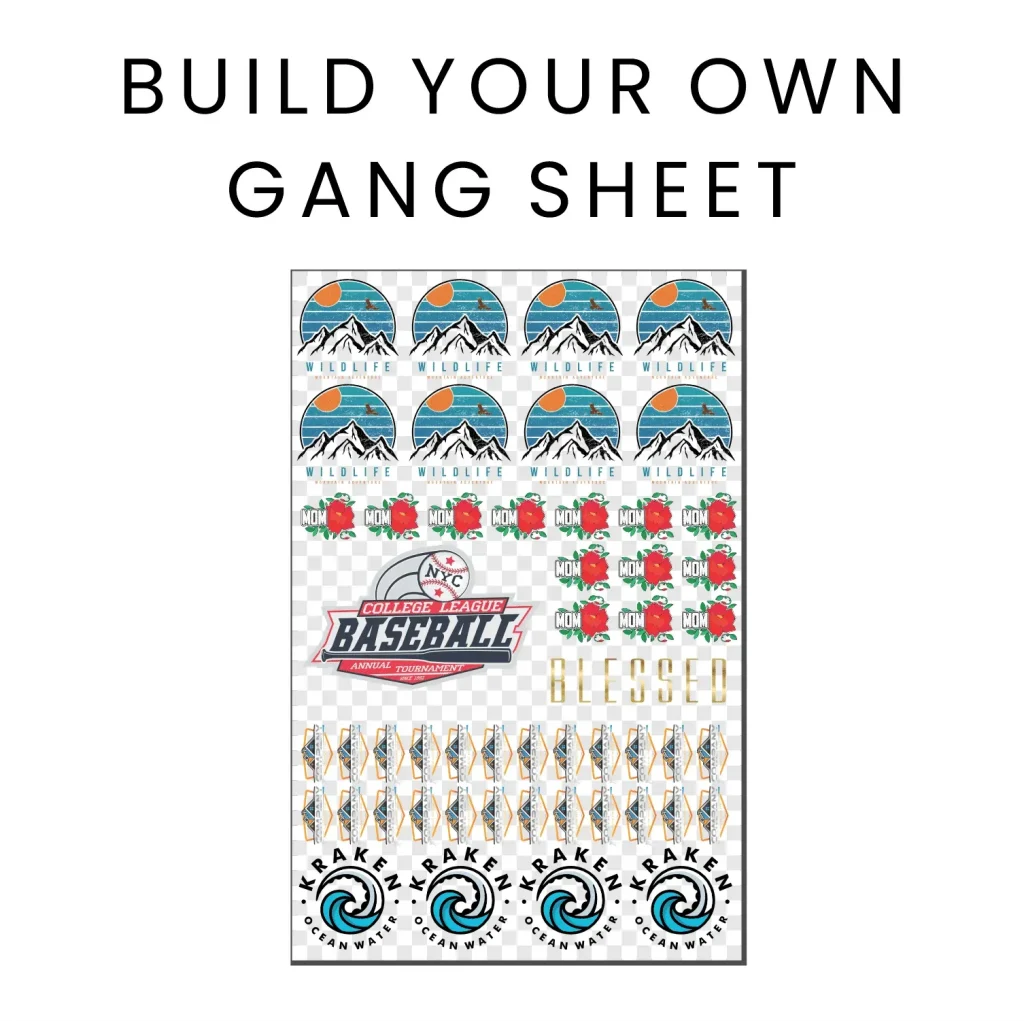

The DTF Gangsheet Builder is a game-changer in the screen printing industry, offering users an innovative solution to streamline their printing processes while maintaining superb print quality. This tool simplifies the gangsheet design layout, allowing for multiple designs to be printed on a single sheet, which not only maximizes efficiency but also cuts costs significantly. Moreover, by adhering to screen printing best practices and incorporating DTF printing tips, users can ensure flawless execution and stunning results. Quality assurance is paramount, and using a DTF Gangsheet Builder aligns perfectly with the latest techniques in print quality assurance, making it an indispensable asset for printers seeking to stay competitive. Dive into the realm of cost efficiency in printing with the DTF Gangsheet Builder and unlock new levels of productivity and creative possibilities.

The Direct to Film (DTF) Gangsheet Generator represents a significant advancement in the world of textile printing, enabling artists and manufacturers to enhance their output effectively. This tool is designed to optimize the organization and arrangement of multiple designs on a single print layout, ensuring that every inch of material is utilized efficiently. Those working in fabric printing can benefit from essential methods that promote the best printing practices, such as ensuring high standards for print resolution and color accuracy. By focusing on elements like material quality and equipment calibration, users can facilitate better adhesion and reduce the likelihood of printing errors. Embracing this innovative technique not only increases production capacity but also fosters a deeper understanding of cost management within the print industry.

Understanding DTF Gangsheet Benefits

Utilizing a DTF gangsheet builder is advantageous for a multitude of reasons, including material conservation and increased production efficiency. By coordinating several designs on a single sheet, screen printers can significantly minimize wasted resources, potentially leading to cost savings that can be passed on to customers. This efficient printing approach not only helps businesses enhance profitability but also contributes to a more sustainable printing practice, making it a win-win solution.

Moreover, the construction of gang sheets allows for a smoother workflow in the printing process. When designs are thoughtfully arranged, printers can achieve higher throughput, ultimately fulfilling more orders in less time. This method bolsters strategic planning in production schedules, enabling businesses to meet tight deadlines while maintaining quality, which is vital for client satisfaction and repeat business.

Key Practices for DTF Gangsheet Design Layout

Effective design layout is paramount when using a DTF gangsheet builder. A cluttered or poorly planned layout can lead to printing errors, with overlapping designs resulting in reduced print quality. Therefore, it’s crucial to allocate sufficient margins and spacing between elements to prevent ink bleed, which can degrade the overall appearance of the finished product. Screen printers should also critically assess the size of each design to ensure a harmonious final output that meets client expectations.

Additionally, aligning designs in a logical and visually appealing manner can enhance the aesthetic appeal of the gang sheet. Consideration should be given not only to the visual arrangement but also to the printing orientation required for each design. By effectively pre-visualizing the layout, printers can minimize adjustments during production, thus promoting a more efficient and streamlined operation.

Material Selection for Optimal DTF Printing

The choice of materials in DTF printing is critical in achieving the best results. Selecting high-quality films and inks can dramatically enhance the final product, impacting color vibrancy, durability, and adhesion. Not all films are created equal; ensuring compatibility with the specific printing equipment is essential for optimal performance. High-grade inks contribute greatly to long-lasting prints and should be chosen carefully to prevent issues like fading over time.

Moreover, investing in premium materials can substantially affect your business’s reputation. When clients receive high-quality products that stand the test of time, their satisfaction levels rise, leading to increased customer loyalty. Businesses must recognize that such investments typically result in higher returns, driven by excellent print quality that meets or exceeds client expectations.

Ensuring Print Quality Assurance

Implementing strict quality control measures is vital when utilizing a DTF gangsheet. Regularly checking samples and conducting thorough inspections throughout the production process helps identify issues such as ink smudging or color mismatches at an early stage. By keeping detailed records of these challenges, printers can develop a troubleshooting guide that mitigates future errors, ultimately enhancing the reliability of their output.

Additionally, beyond monitoring outputs, creating a quality assurance protocol ensures consistency in print results. Continuous calibration of printing equipment should be a priority, as it establishes a baseline for quality. This ongoing attention to detail helps sustain high standards in both the production process and the end results, positioning the business as a trusted provider in the competitive screen printing market.

Addressing Common Challenges in DTF Printing

DTF printing with gang sheets can present challenges that, if unaddressed, can negatively impact production quality. Ink smudging, for instance, often arises from inadequate design spacing or subpar material selection. By training operators on proper setup and conducting regular equipment checks, businesses can minimize these risks and improve overall print quality. Attention to detail during setup is key, as it leads to smoother production processes.

Another common challenge is poor adhesion, typically associated with inadequate temperature settings or incorrect film choices. Screen printers must diligently follow the manufacturer’s guidelines for ink and film compatibility, ensuring optimal configurations for the best results. By routinely reviewing and adjusting these parameters, businesses can alleviate many common issues and bolster the quality of their output.

Maximizing Cost Efficiency in Printing

Cost efficiency is a crucial consideration for businesses in the screen printing industry. The ability to create multiple designs on a single DTF gangsheet not only results in time savings but also reduces material consumption. By minimizing waste through effective planning and production practices, businesses can enhance their bottom line, allowing for more competitive pricing in a crowded marketplace.

Furthermore, increased production output contributes to greater revenue opportunities. Higher volumes of printed products can lead to decreased overhead costs per unit, enhancing profitability. This model encourages printers to optimize their operations continuously, ensuring they capitalize on every element of their workflow for improved financial performance.

Frequently Asked Questions

What are the best practices for using a DTF Gangsheet Builder in screen printing?

To achieve optimal results when using a DTF Gangsheet Builder, focus on proper design arrangement to prevent ink bleeding, choose high-quality materials for better adhesion, regularly calibrate your equipment for consistent print quality, and implement strict quality control measures to catch issues early.

How can I improve print quality assurance with DTF Gangsheet Builder?

Improving print quality assurance with a DTF Gangsheet Builder involves ensuring consistent ink distribution during printing, using premium inks and films, and regularly checking samples from each batch to detect problems like color mismatches or smudging.

What are effective DTF printing tips for maximizing efficiency?

Effective DTF printing tips to maximize efficiency include optimizing your gangsheet design layout to combine multiple images for a single print run, maintaining a well-calibrated printer, and selecting compatible materials that enhance print resolution and durability.

Why is material selection important when using a DTF Gangsheet Builder?

Material selection is crucial when using a DTF Gangsheet Builder because high-quality films and inks greatly influence the final print’s adhesion, color vibrancy, and overall durability, ensuring a superior product for your customers.

How does gangsheet design layout affect cost efficiency in printing?

A well-planned gangsheet design layout enhances cost efficiency in printing by reducing material waste and maximizing production volume, allowing multiple designs to be printed simultaneously, which leads to faster turnaround times and increased profitability.

What common challenges should I expect with DTF Gangsheet printing?

Common challenges in DTF Gangsheet printing include ink smudging due to improper spacing, poor adhesion linked to material selection, and color mismatches from outdated equipment. Addressing these issues requires careful attention to design, material choices, and regular printer maintenance.

| Key Point | Details |

|---|---|

| Understanding Gang Sheets | A collection of multiple designs printed on a single sheet that conserves material and expedites the printing process. |

| Design Arrangement | Proper spacing and orientation are crucial to avoid ink bleed and ensure quality prints. |

| Material Selection | Use high-quality films and premium inks to enhance adhesion and print resolution. |

| Equipment Calibration | Regularly calibrate printers for consistent ink distribution and image quality. |

| Quality Control | Implement strict quality checks for early detection of issues and maintain records of challenges. |

| Common Challenges | Be aware of issues like ink smudging, poor adhesion, and color mismatches and take preventive measures. |

| Enhancing Profitability | Streamlined workflow and cost reductions lead to higher production volumes and increased revenue. |

Summary

DTF Gangsheet Builder is a powerful tool that can dramatically transform the screen printing process. By mastering the key best practices outlined in this guide, such as proper design arrangement, careful material selection, equipment calibration, and stringent quality control, screen printers can significantly enhance the quality of their outputs. Understanding and overcoming common challenges like ink smudging and poor adhesion ensures a smoother production experience. Ultimately, these strategies not only improve efficiency but also boost profitability, allowing businesses to thrive in a competitive market. As technology evolves, continuous learning and adaptation in the use of DTF Gangsheet Builders will help operators stay ahead of the curve, leading to increased customer satisfaction and sustained success in the screen printing industry.