In the dynamic landscape of garment printing, the DTF Gangsheet Builder is revolutionizing how businesses approach Direct-to-Film (DTF) printing. This innovative gangsheet software facilitates the efficient arrangement of multiple designs on a single sheet, paving the way for enhanced print workflow optimization and cost-saving printing techniques. By utilizing the DTF Gangsheet Builder, printers can maximize material usage, significantly reduce waste, and streamline their operations. As the demand for high-quality garment printing rises, integrating this advanced technology is essential for businesses aiming to stay ahead of the curve. Join us as we delve deeper into the benefits and functionalities of this remarkable tool that is shaping the future of garment printing technology.

The DTF Gangsheet Builder, sometimes referred to as DTF layout software, plays a crucial role in modern printing solutions. This advanced tool not only supports Direct-to-Film printing but also enhances print workflow efficiency by ensuring that multiple designs are arranged optimally on one sheet. By leveraging this gangsheet creation technology, printing businesses can adopt smarter, cost-effective processes that eliminate unnecessary resource usage. With the increasing significance of garment printing technology in the industry, using such innovative software is essential for maintaining competitiveness. In this article, we will explore how these cutting-edge solutions can elevate your printing operations to new heights.

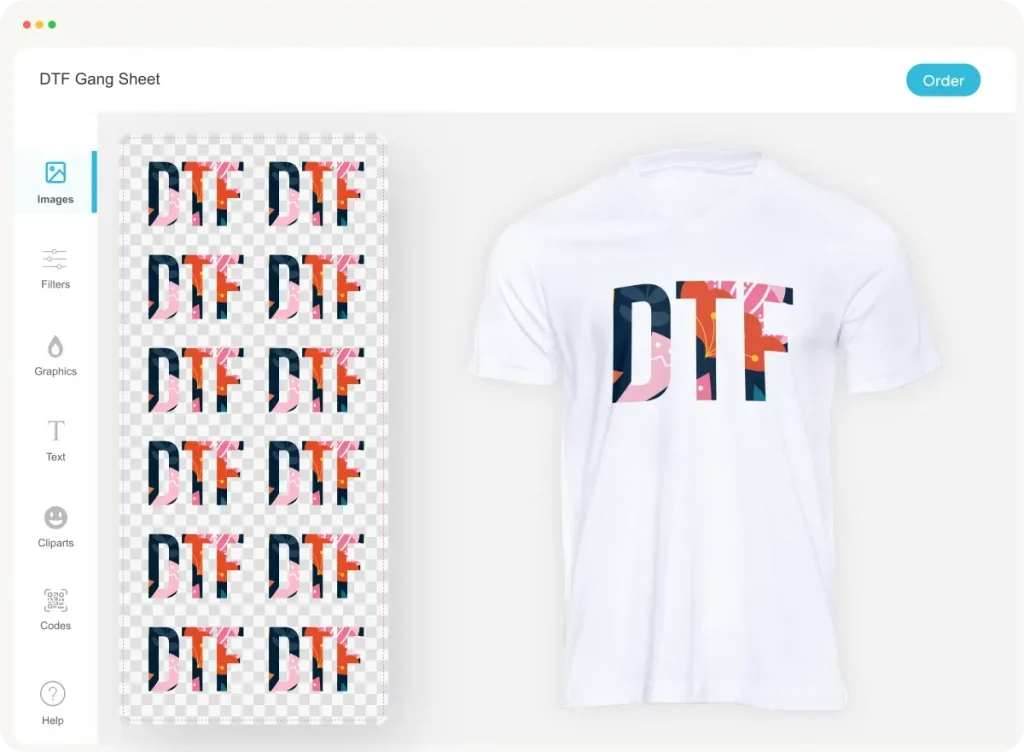

Understanding the DTF Gangsheet Builder’s Functionality

The DTF Gangsheet Builder is an innovative tool that streamlines the Direct-to-Film (DTF) printing process by efficiently arranging numerous designs on a single sheet of film. This software allows users to optimize material usage, significantly reducing waste. By maximizing the placement of various graphics on one sheet, businesses can lower the amount of film needed for each print run, leading to considerable savings over time.

In addition to material savings, the DTF Gangsheet Builder enhances productivity within the print workflow. By automating the layout of designs, printers can transition smoothly from design stage to printing. This not only shortens turnaround times but also fosters a more organized printing process, ultimately resulting in higher-quality outputs for customers.

The Benefits of Using Gangsheet Software in Garment Printing

Gangsheet software revolutionizes garment printing by allowing multiple designs to be printed simultaneously on a single sheet. This benefit leads to drastic reductions in production costs as many different designs can be printed in one operation, cutting down the time required for setup and minimizing labor costs. Furthermore, using gangsheet software helps in maximizing the utilization of printing resources, ultimately decreasing the overall operational costs.

Moreover, this software aids in optimizing print workflows. By simplifying tedious layout adjustments and automating placement of designs, gangsheet software integrates seamlessly into existing print processes, facilitating better resource management and improved error reduction. This technology represents a significant step toward efficiency in Direct-to-Film printing.

Cost-Saving Printing Techniques with DTF Technology

One of the most compelling advantages of DTF technology is the ability to implement cost-saving printing techniques effectively. By utilizing a DTF gangsheet builder, printing businesses can cut costs on both material and labor. The efficient arrangement of designs reduces the waste of film materials, while also allowing for more efficient machine usage across different print jobs.

In addition, adopting a DTF gangsheet builder can pave the way for better resource allocation. Since DTF printing technology yields higher quality graphics on various textiles, businesses can achieve excellent results without needing to invest heavily in a multitude of materials. This innovation in garment printing truly exemplifies how cost-saving techniques can coalesce with advanced printing technology.

Enhancing Print Workflow with DTF Advancements

Recent advancements in DTF gangsheet technology have vastly transformed print workflow optimization. The latest software updates include features that allow for real-time layout adjustments, streamline the printing process, and reduce the overall effort required in preparing print jobs. As printing demands evolve, incorporating these enhancements can elevate production capabilities and maintain competitiveness in the garment printing market.

Furthermore, the integration of DTF gangsheet builders with other printing systems improves productivity by providing a cohesive network of design and output workflows. This harmonization minimizes errors associated with manual interventions and assures the timely delivery of quality products. In a fiercely competitive market, these productivity and efficiency gains are essential for achieving long-term success.

Educational Resources for DTF Printing Success

To maximize the potential of a DTF gangsheet builder, access to quality educational resources is vital. Tutorials and guides can offer insights into best practices for using gangsheet software effectively. This includes tips on how to layout designs efficiently and manage printer settings, which are crucial for achieving optimal print quality and workflow efficiency.

Moreover, industry professionals and manufacturers provide case studies that showcase real-world applications of DTF printing technologies. These educational resources equip businesses with the knowledge necessary to implement DTF printing strategies confidently, thereby enhancing their production capabilities and fostering sustainable practices.

Exploring the Expanding Marketplace for DTF Solutions

As the DTF printing industry continues to grow, the marketplace has expanded to include a variety of dedicated software solutions designed specifically for DTF applications. Companies like Epson and Brother have launched versatile printers and software that cater to both small and large-scale businesses, ensuring that everyone has access to valuable resources that can enhance their printing operations.

With a broader array of options available, businesses can select the right combination of equipment and software to suit their unique needs. This enhanced accessibility fosters innovation and allows for improvements in garment printing techniques, ultimately pushing the boundaries of what’s possible in fashion and textile applications.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work?

The DTF Gangsheet Builder is a specialized software design tool that optimizes the arrangement of multiple designs on a single Direct-to-Film (DTF) sheet. It enables garment printers to maximize material usage by fitting as many graphics as possible onto the film, resulting in reduced waste and lower production costs.

How does a DTF Gangsheet Builder optimize print workflows?

A DTF Gangsheet Builder streamlines print workflows by automating layout adjustments, enhancing batch processing, and integrating design with production tasks. This ensures efficient use of materials, minimizes manual errors, and speeds up transition times from design to print.

What are the cost-saving benefits of using a DTF Gangsheet Builder?

Utilizing a DTF Gangsheet Builder allows printers to minimize waste and effectively plan design placements, leading to significant cost savings on film materials. Additionally, it reduces operational expenses through optimized workflows and decreased resource wastage.

Can a DTF Gangsheet Builder support various garment printing technologies?

Yes, a DTF Gangsheet Builder is designed to be compatible with various garment printing technologies, including direct-to-garment (DTG) and sublimation. This flexibility makes it a valuable addition to any print operation looking to improve efficiency and quality.

What recent advancements have been made in DTF Gangsheet Builder technology?

Recent advancements in DTF Gangsheet Builder technology include enhanced design software features such as smart design recognition and instant layout adjustments. These improvements make it easier for users to create optimized gangsheet layouts quickly and effectively.

Where can I find educational resources for using a DTF Gangsheet Builder?

Educational resources for using a DTF Gangsheet Builder can be found through manufacturers’ websites, industry tutorials, and online case studies. These materials provide best practices for layout optimization, printer settings management, and overall workflow enhancement.

| Key Feature | Description |

|---|---|

| Maximize Material Usage | Reduces waste by arranging multiple designs on a single sheet. |

| Lower Production Costs | Cuts down chances of overage and waste of resources through bulk printing. |

| Simplifying Workflow | Enhances the design-to-press transition for improved efficiency. |

| Automated Layout Adjustments | Intelligent layout adjustments ensure optimal design fit without quality loss. |

| Enhancing Batch Processing | Enables simultaneous management of multiple designs, reducing labor and errors. |

| Integrating Design and Production | Seamless transition from design to printing improves quality control and speed. |

Summary

The DTF Gangsheet Builder is a transformative tool that revolutionizes print workflows in the garment printing industry. By adopting this advanced software, businesses can unlock a plethora of benefits including enhanced efficiency, reduced material costs, and streamlined operations. With the latest innovations in design automation, cost-saving practices, and comprehensive educational resources, integrating a DTF Gangsheet Builder into your print operations not only positions your business for success but also fosters sustainable growth in an increasingly competitive market.