In the competitive landscape of custom apparel printing, the DTF Gangsheet Builder emerges as a game-changing technology that revolutionizes the way designs are transferred onto fabric. Unlike traditional printing methods that often require multiple steps and extensive setup, DTF printing streamlines the process, allowing creators to efficiently produce high-quality prints on various materials with stunning vibrancy and detail. Whether you’re considering DTF vs screen printing, understanding the advantages of DTF printing can open up new avenues for your design projects. With its cost-effectiveness and versatility, the DTF Gangsheet Builder is quickly becoming the preferred choice for businesses aiming to meet the rising demand for customized apparel. As you explore your options, consider how this innovative approach can elevate your printing capabilities beyond what traditional methods can offer.

In the realm of personalized garment production, the Direct-to-Film (DTF) Gangsheet Builder stands out as a premier tool for creators and businesses alike. This advanced printing solution excels in delivering intricate designs and vibrant colors, streamlining the custom textile printing process compared to established methods such as screen printing. With the rise of innovative printing technologies, understanding the distinction between DTF and conventional techniques is crucial for any designer looking to enhance their offerings. The advantages of DTF printing—like its adaptability to various fabrics and efficient output—make it an attractive option for modern-day printing demands. As we delve deeper into this topic, we will uncover how the DTF Gangsheet Builder represents a significant shift in the custom apparel landscape, catering to both small-scale creators and large production needs.

Understanding DTF Printing Technology

DTF printing, or Direct-to-Film printing, introduces a transformative approach to the custom apparel industry. This method involves printing designs onto a specialized film, which is then transferred onto fabric using heat. The technology thrives on versatility and offers the ability to produce vivid colors and intricate details, making it suitable for a wide range of fabric types. As brands move towards more customized solutions, the demand for DTF printing continues to increase, particularly due to its efficiency in producing small batch runs with high-quality outputs.

One of the primary benefits of DTF printing is its adaptability to various materials, including cotton, polyester, and blends. Unlike traditional screen printing, which often has limitations on fabric compatibility, DTF can work seamlessly on both light and dark fabrics without requiring a base layer. This aspect allows for creative freedom and the ability to produce complex, multi-colored designs with less hassle. As businesses pivot towards personalized apparel, understanding the mechanics of DTF printing becomes crucial for leveraging its full potential.

Advantages of DTF Gangsheet Builder for Custom Apparel

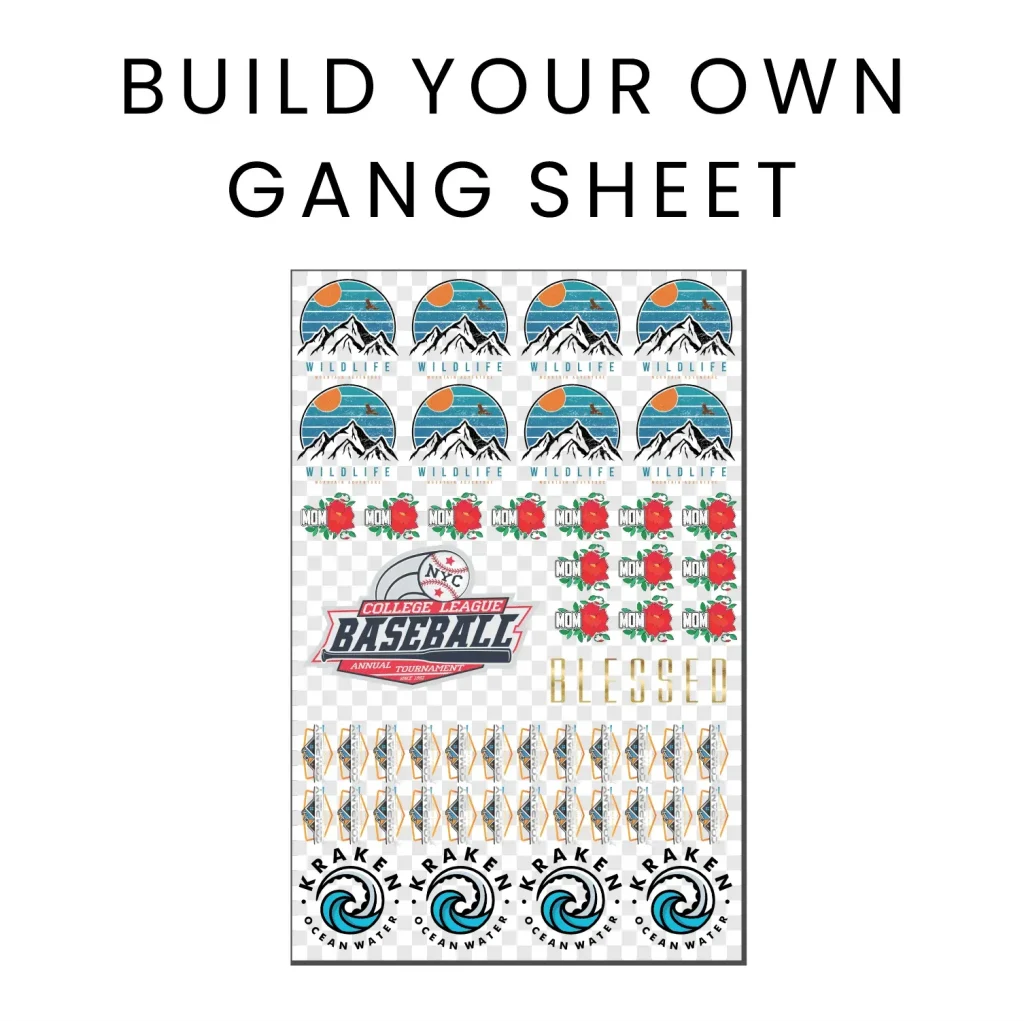

The DTF Gangsheet Builder is revolutionizing how businesses approach custom apparel production. This innovative tool enables users to print multiple designs on a single sheet, optimizing the use of materials while reducing waste. One of the standout features of this method is its ability to handle various designs in one go, which is a major advantage for small to mid-sized businesses aiming for efficiency without sacrificing quality. The reduced setup time compared to traditional printing methods is another significant benefit that streamlines the production process.

Moreover, the Gangsheet Builder caters to smaller orders effectively, making it easier for companies to experiment with new designs without the risk of significant loss. Unlike screen printing, where multiple setups can lead to increased costs and extended lead times, DTF printing offers a cost-effective solution that is particularly appealing for companies testing market response. As trends in custom apparel shift towards more personalized options, tools like the DTF Gangsheet Builder are essential for staying competitive.

Comparing DTF Printing and Screen Printing

When assessing DTF printing against traditional screen printing, it’s essential to consider factors such as print quality, cost-efficiency, and production time. DTF printing excels in delivering high-resolution prints that capture fine details and vibrant colors. This method eliminates the limitations of color separations often found in screen printing, allowing for full-color designs in a single pass. However, screen printing holds its ground with its robust, opaque inks that are particularly durable, making it a favored choice for bulk orders.

Cost-effectiveness varies significantly between the two methods, especially concerning order quantity. DTF is particularly beneficial for low to medium-sized batches where screen printing can become inefficient due to its setup requirements. Businesses should weigh these elements carefully; DTF can facilitate greater creative expression through diverse fabric compatibility, while screen printing may still prove beneficial for large-scale productions where longevity and material costs are key factors.

Material Compatibility and Versatility in DTF Printing

One of the hallmark features of DTF printing is its extensive material compatibility. This method can effectively print on a variety of fabrics, including cotton, polyester, and fabric blends, which is a significant advantage over traditional screen printing that often requires specific types of material. The ability to print on both dark and light fabrics without a base layer makes DTF both versatile and appealing to businesses looking to expand product offerings.

Additionally, DTF’s high-resolution print quality allows for complex designs that can include gradients and fine details that might be challenging to replicate through screen printing. As customer demands evolve towards more intricate and personalized designs, having a printing method capable of such versatility opens up numerous opportunities for innovation in custom apparel.

The Cost Dynamics of DTF vs. Screen Printing

When evaluating the financial aspects of DTF printing versus screen printing, it’s crucial to examine setup costs, production times, and waste management. DTF printing generally requires lower initial investment and can be more cost-effective for smaller runs due to its lower setup costs. This aspect allows businesses to experiment with designs and test the market without incurring heavy financial burdens typical with screen printing setups, especially for multi-color designs.

In contrast, screen printing tends to shine in larger production runs. The economies of scale significantly enhance its cost per unit, making it more suitable for massive orders where durability is paramount. However, businesses need to consider the additional resources and time required for setup and the increased waste during transitions between colors, which can negate some benefits. Understanding these cost dynamics is essential for making informed decisions in the custom apparel market.

Future Trends in Custom Apparel Printing

As the landscape of custom apparel continues to evolve, trends indicate a significant shift towards on-demand printing solutions that offer personalization and efficiency. Techniques like DTF printing are at the forefront of this change, capable of delivering high-quality outputs in reduced timeframes. The appeal of DTF lies not only in its production speed but also in its capacity to engage customers through individualized products, aligning with current consumer preferences for unique and tailored apparel.

Moreover, the integration of advanced printing technologies will likely further enhance the customization capabilities within the industry. As tools like the DTF Gangsheet Builder improve, businesses will find themselves equipped to handle more complex orders more efficiently than ever. This adaptability will be crucial as trends in custom apparel continue to shift towards sustainability and on-demand services, positioning DTF printing as a key player in the future of the printing landscape.

Frequently Asked Questions

What are the main advantages of using the DTF Gangsheet Builder for custom apparel printing?

The DTF Gangsheet Builder offers several key advantages for custom apparel printing, such as versatility across various fabric types, the ability to produce vibrant colors and detailed designs, and cost-effectiveness by reducing waste and setup costs. This method is especially beneficial for smaller production runs, allowing for high-quality outputs without the extensive setup times required by traditional methods.

How does DTF printing compare to traditional printing methods like screen printing?

DTF printing differs from traditional methods like screen printing in terms of setup efficiency, color versatility, and material compatibility. While DTF can produce full-color prints in a single pass without needing multiple screens, screen printing is more suited for high-volume orders and simpler designs due to its economies of scale.

What types of fabrics can the DTF Gangsheet Builder be used with?

The DTF Gangsheet Builder is highly versatile and can be used with a wide range of fabrics, including cotton, polyester, and fabric blends. It excels in printing on both light and dark materials, making it a preferred choice for diverse custom apparel projects.

Can DTF printing deliver high-quality results for detailed designs?

Yes, DTF printing is known for its ability to produce high-resolution prints with intricate details, making it ideal for complex designs. This capability allows for rich color variations and defined graphics, which can sometimes be challenging to achieve with traditional screen printing methods.

What are the cost implications of using the DTF Gangsheet Builder versus screen printing?

Using the DTF Gangsheet Builder generally incurs lower setup costs and reduces material waste compared to screen printing, making it a more economical choice for smaller jobs. In contrast, screen printing becomes cost-effective for larger production runs, as the cost per unit decreases significantly with volume.

Is DTF printing suitable for large production runs compared to traditional methods?

While DTF printing is excellent for small to mid-sized production runs due to its rapid turnaround time and flexibility, traditional methods like screen printing remain the superior choice for large-scale production due to their durability and lower cost per unit for bulk orders.

| Feature | DTF Gangsheet Builder | Traditional Methods (Screen Printing) |

|---|---|---|

| Versatility | Can be used on various fabrics including cotton and polyester. | Best for specific materials, might require preparation based on fabric type. |

| Color and Detail | High-resolution images with intricate details in full color. | Bold prints but may lack color variation without extensive setup. |

| Cost-Effectiveness | Lower setup costs, reduces waste, ideal for smaller runs. | Economical for large runs but higher costs per unit in smaller quantities. |

| Setup and Turnaround Time | Rapid design printing onto transfer film, speeding up production. | Labor-intensive setup, especially for multi-color designs, leading to longer times. |

| Durability | Good for detailed designs but may not withstand heavy washes as well. | Produces durable prints, especially suited for heavy use and washing. |

Summary

DTF Gangsheet Builder is a revolutionary printing solution that offers exceptional flexibility and quality for custom apparel production. This method stands out due to its ability to print vibrant, high-resolution designs on a variety of fabrics, making it a go-to choice for businesses looking to produce intricate artwork in smaller quantities. As the industry evolves, adopting the DTF Gangsheet Builder can enhance production efficiency while catering to diverse customer preferences. By combining cost-effectiveness with agility, the DTF method not only meets modern demands for customization but also positions your business for success in the competitive landscape of textile printing.