The DTF printing process, or Direct-to-Film printing, has emerged as a revolutionary technique in the realm of custom apparel and textile printing. This sophisticated method bridges the gap between vibrant digital designs and high-quality textile results, ensuring that even the most intricate designs can be transferred seamlessly onto fabrics. DTF printing not only allows for exceptional color fidelity but also supports sustainable printing methods, using eco-friendly inks and adhesives. As it evolves, this technique reshapes industry standards, making it easier for businesses to meet consumer demand for personalized products. Join us as we delve into the five simple steps of the DTF printing process, from the initial design creation to the final touch-ups that ensure a stunning product.

Understanding the intricacies of the DTF printing method opens up a world of possibilities for artists and businesses alike. Often referred to as Direct-to-Film technology, this innovative approach to textile printing enhances the ability to produce custom apparel with vivid detail and style. By utilizing specialized DTF transfer film, printers can achieve high-quality results that cater to a range of fabric types and designs. Moreover, this printing method is gaining traction due to its compatibility with sustainable printing practices, which are increasingly in demand. Let’s explore how this transformative printing technique operates, step by step, revealing its potential for creativity and efficiency in the apparel industry.

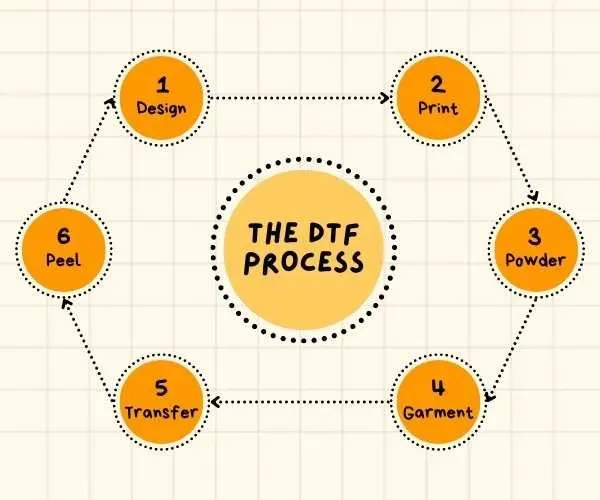

The Essential Steps of the DTF Printing Process

The DTF printing process encompasses several key stages that ensure high-quality and durable outcomes for custom apparel. From initial design creation to the final touches, each phase is integral to the overall success of the print job. Designers must create intricate graphics that can transfer seamlessly onto fabrics, requiring high-resolution artwork and compatible graphic software. Following this, the meticulous preparation and application of DTF transfer film come into play, setting the foundation for vibrant and lasting prints.

Once the film is prepared and the adhesive is cured effectively, the application to fabric marks a significant turning point in the DTF printing journey. During this step, precise temperature and pressure control during the transfer process are crucial to achieving adhesion without compromising print quality. Each detail throughout this process—from design to transfer—plays a crucial role in ensuring that the final product meets the expectations of both businesses and customers, showcasing the versatility and effectiveness of DTF technology.

Understanding Direct-to-Film Printing

Direct-to-Film (DTF) printing is revolutionizing how businesses approach textile printing. Unlike traditional methods that might limit designs or materials, DTF allows for intricate graphics and a broad fabric spectrum. This flexibility not only attracts designers but also appeals to retailers looking for unique custom apparel that stands out in the market. By utilizing specialized DTF printers, companies can efficiently deliver quality prints that cater to current fashion trends, addressing the growing demand for personalization in clothing.

Furthermore, DTF printing showcases the capability of producing detailed designs with vivid colors, enhancing the aesthetic appeal of clothing items. As businesses strive for versatility and quality, adopting methods like DTF printing aligns perfectly with consumer preferences, making it a preferred choice for modern apparel businesses. The focus on delivering high-quality products through advanced techniques positions DTF printing as a forward-thinking solution in the competitive landscape of textile printing.

Advantages of DTF Transfer Film

The use of DTF transfer film presents numerous advantages for both print providers and customers. One notable benefit is the high level of detail and color vibrancy achievable with this method. DTF transfer film can capture the nuances of designs, making them pop on various fabrics without losing quality over time. Furthermore, the ability to apply these transfers to dark or colorful textiles without concerns about underbase printing provides decorators with endless creative possibilities, promoting innovation in the custom apparel market.

Additionally, DTF transfer film supports sustainable printing methods by using eco-friendly inks and adhesives. Many companies are now prioritizing environmental responsibility in their operations, and opting for DTF printing represents a shift towards more sustainable practices. As businesses continue to embrace green technologies, understanding and utilizing DTF transfer film can lead to not just aesthetic improvements but also increased environmental consciousness in textile production.

Textile Printing Techniques: Comparing DTF with Other Methods

When it comes to textile printing, various techniques are available, and each has its strengths and weaknesses. DTF printing stands out in comparison to traditional methods such as screen printing or heat transfer, thanks to its versatility and ease of use. While screen printing may require extensive setups and color separations, DTF simplifies the process by allowing for full-color prints directly from design files without multiple screens. This efficiency significantly reduces turnaround times while maintaining high-quality results.

Moreover, unlike methods that may only adhere to cotton or polyester, DTF can be applied to a wider range of fabrics, expanding its usability for creators. The ability to print on both light and dark materials enhances its appeal for custom apparel printing, offering options that meet diverse market demands. Ultimately, businesses looking to stay competitive find that embracing innovative techniques like DTF printing can yield substantial benefits compared to more traditional textile printing methods.

Sustainable Printing Methods in DTF

As the printing industry shifts focus toward sustainability, DTF printing adopts several eco-friendly practices that resonate with today’s environmentally conscious consumers. One of the primary elements is the use of water-based inks, which minimize harmful environmental impacts compared to solvent-based alternatives. This not only enhances the appeal of DTF printing for businesses committed to sustainability but also aligns with consumer preferences for responsible brands.

Additionally, DTF’s technique of using an adhesive powder can be controlled to reduce waste, making it a more efficient option for high-volume orders. This approach helps companies meet production demands without generating excess byproducts, which is often seen in traditional printing methods. By integrating sustainability into the DTF printing process, businesses can effectively respond to market trends while contributing positively to environmental protection.

The Future of DTF Printing Technology

The future of DTF printing technology looks promising as continuous advancements in digital image processing and material science evolve the industry. With the rapid growth of e-commerce and personalized products, DTF’s capability to produce intricate designs at scale aligns perfectly with market demands. Future improvements may include enhanced printers that utilize even more sustainable resources, enabling print providers to offer high-quality results while adhering to eco-friendly practices.

Moreover, as techniques develop, we may see DTF printing gain even wider acceptance across different sectors, from fashion to promotional products. The continuous exploration of new substrates and inks can lead to innovative applications that expand the boundaries of textile printing. By staying ahead of technological advancements and customer expectations, businesses that invest in DTF technology can remain at the forefront of the ever-evolving print landscape.

Frequently Asked Questions

What is the DTF Printing Process and how does it work?

The DTF (Direct-to-Film) printing process involves several key steps: first, designers create vibrant artwork using software. Next, this design is printed onto a specialized DTF transfer film using eco-friendly inks. The adhesive powder is applied and cured, followed by transferring the design onto the chosen fabric through a heat press. This method allows for high-quality, detailed prints, making it ideal for custom apparel.

What makes DTF Printing suitable for custom apparel printing?

DTF printing is highly suitable for custom apparel printing due to its ability to produce vibrant, full-color designs that can be applied to various fabrics. The process is flexible and supports intricate designs, which is perfect for fashion trends. Additionally, the environmentally friendly inks and reliable adhesive contribute to the sustainability of this textile printing technique.

What types of fabrics can be used with the DTF Printing process?

The DTF printing process is versatile and can be applied to a wide range of fabrics, including cotton, polyester, and blends. This capability allows businesses to offer custom apparel across different material choices, catering to diverse consumer needs while ensuring high-quality and durable prints.

How does the DTF Transfer Film contribute to print quality?

DTF transfer film plays a crucial role in determining print quality by providing a smooth surface for the eco-solvent or water-based inks to adhere to. The film is designed to hold the adhesive properly during the curing process, ensuring a strong bond with the fabric. This results in vibrant images that maintain their integrity even after multiple washes.

Are there sustainable printing methods associated with DTF Printing?

Yes, DTF printing incorporates sustainable printing methods by using eco-solvent and water-based inks, which are less harmful to the environment compared to traditional inks. The adhesive powders used are also formulated to minimize waste and ensure a more environmentally friendly printing process, making DTF a forefront technology in sustainable textile printing.

What are the main advantages of using DTF Printing over other textile printing techniques?

DTF printing offers several advantages over other textile printing techniques, including the ability to produce high-resolution, complex designs with vivid colors. It allows for a broad fabric compatibility and provides excellent washability. Additionally, the process is faster than traditional screen printing, making it more efficient for small to medium runs of custom apparel.

| Step | Description |

|---|---|

| 1. Design Creation | The initial step where designers create artwork using software tools like Adobe Illustrator, ensuring vibrant colors and high resolution for better transfer quality. |

| 2. Film Preparation | Printing the design onto specialized DTF transfer film using eco-solvent or water-based inks, followed by even application of adhesive powder. |

| 3. Curing the Adhesive | Melting and bonding the adhesive to the ink using a curing oven or heat press, crucial for enhancing the print’s durability. |

| 4. Application to Fabric | Transferring the design onto the fabric with a heat press, requiring precise temperature and pressure settings for best results. |

| 5. Final Touches | Cooling the transferred fabric and possibly re-pressing with protective layers to ensure quality and integrity of the print. |

Summary

The DTF printing process stands at the forefront of modern textile printing, transforming digital designs into tangible products through a structured five-step method. This innovative approach begins with design creation, where high-resolution artwork is crafted, followed by meticulous film preparation and adhesive curing. The actual transfer to fabric is executed with precision, ensuring durability and washability of the designs. Finally, quality assurance measures are applied to solidify the print’s integrity. As trends evolve, focusing on sustainability and versatility, the DTF printing process is not only showcasing its potential in producing stunning visual effects but is also pioneering paths towards eco-friendliness. Thus, understanding and adopting the DTF printing process can empower businesses to thrive in a competitive landscape.