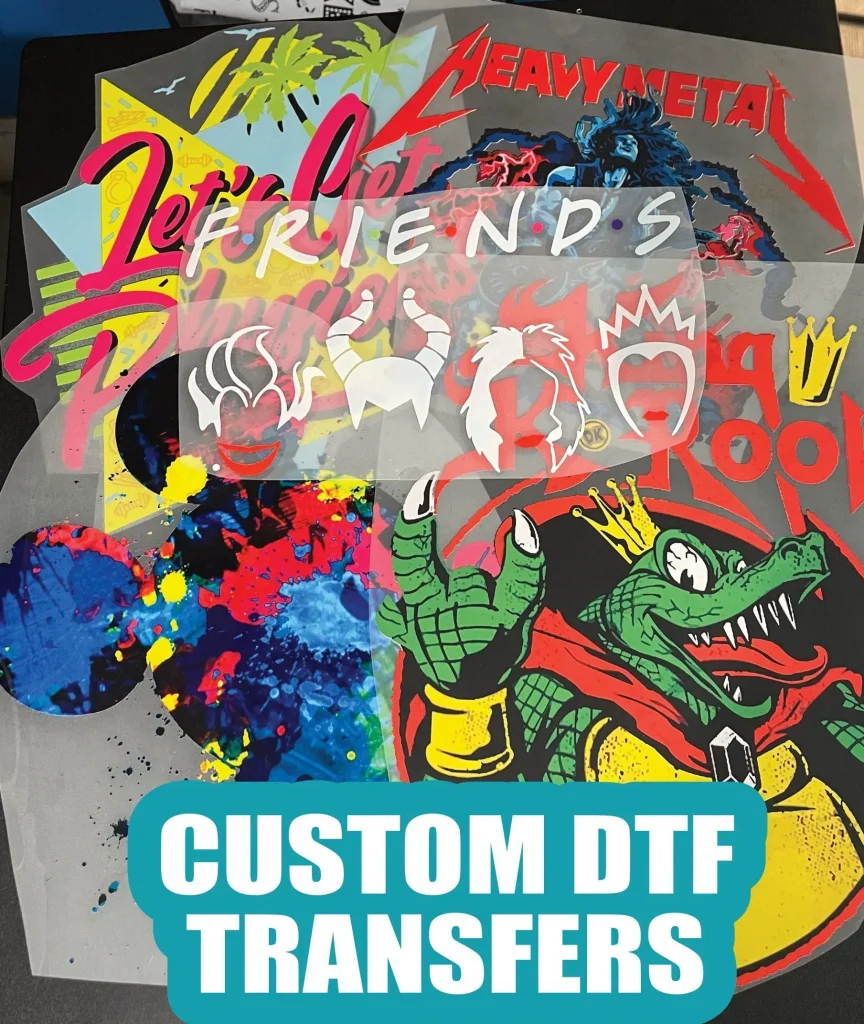

In the realm of custom printing, **DTF transfers** (Direct to Film) have emerged as a revolutionary technique that caters to the diverse needs of designers and businesses alike. This innovative method allows for high-quality prints on a wide variety of materials, from cotton to polyester, making it an ideal choice for apparel and promotional products. The durability of DTF transfers ensures that designs maintain their vibrancy and integrity even after repeated washes, setting a new standard in printing technology. As a cost-effective printing solution, DTF transfers enable small businesses to produce customized designs without the burden of high setup costs, fostering creativity and accessibility. In this article, we delve into the top five benefits of DTF transfers, showcasing why they have become a preferred choice in the printing industry.

Known for their efficiency and versatility, DTF (Direct to Film) printing offers an array of advantages for those looking to enhance their design projects. This approach allows for direct application of vibrant, intricate designs onto various fabrics, including both natural and synthetic options. The ease of use associated with this printing method simplifies production processes, making it an excellent fit for small and large businesses alike. Additionally, the long-lasting quality of DTF prints ensures that your creations stand the test of time, resisting fading and wear. As the demand for customization escalates, embracing DTF technology presents a fantastic opportunity for anyone in the custom printing market.

Understanding DTF Transfers and Their Advantages

DTF transfers, or Direct to Film transfers, represent a significant advancement in printing technology, particularly for apparel and fabric applications. Unlike traditional methods such as screen printing or heat transfer methods, DTF involves printing on a special film that is then applied to the fabric, ensuring vibrancy and detail. This process yields remarkable results across a variety of textile types, including cotton and polyester, enabling designers to achieve the exact look and feel they desire. As a result, businesses can diversify their product offerings without investing heavily in multiple printing technologies.

The advantages of DTF transfers extend beyond mere versatility. For instance, they offer the capability to create detailed designs with depth and color vibrancy that are often hard to replicate with other methods. This makes DTF an appealing choice for businesses targeting niche markets that demand high-quality, custom prints. Additionally, as fashion trends become more varied and personalized, the adaptability of DTF transfers allows companies to stay ahead of the competition, catering to specific client needs with ease.

DTF Printing Process Explained

The DTF printing process begins with creating a digital design that is printed onto a specialized film using high-quality, pigment-based inks that are known for their vibrancy. Once printed, a powder adhesive is applied and cured, allowing the ink to bond securely with the adhesive prior to transfer. Finally, the film is placed on the chosen fabric, and heat is applied using a heat press. This method not only ensures that the design is transferred cleanly and accurately but also provides excellent wash durability, making it ideal for everyday apparel.

Once the transfer is complete, the DTF print boasts an impressive lifespan while retaining its vivid colors and intricate details, even after multiple washes. This process is becoming increasingly popular amongst small businesses and creatives who require a reliable method for producing quality garments on demand. With less setup time than methods such as screen printing, DTF allows for rapid production cycles without compromising the level of detail that customers expect from custom garment design.

Durability of DTF Transfers: A Key Selling Point

Durability is paramount in the world of custom printing, and DTF transfers excel in this regard. Once applied, the ink forms a strong bond with the fabric, which not only enhances the vibrancy of the print but also ensures that it withstands frequent washing and wear. Unlike some other printing techniques, DTF transfers resist peeling, cracking, and fading, allowing them to maintain their aesthetic appeal even after many uses.

This durability not only contributes to customer satisfaction but also builds brand loyalty, as consumers increasingly seek products with lasting quality. For businesses, the durability of DTF transfers is a compelling reason to choose this printing method, ensuring that their products remain in excellent condition over time. This reliability in the face of daily use makes DTF a preferred choice for apparel manufacturers looking to provide their customers with lasting value.

The Versatility of DTF on Various Fabrics

One of the standout benefits of DTF transfers is their versatility on a wide array of fabrics. DTF is suitable for cotton, polyester, blends, and even specialty materials, providing designers with the flexibility they need to create stunning pieces across different mediums. This capability allows businesses to cater to a diverse clientele, producing custom designs for everything from casual wear to high-performance sports apparel.

Using DTF on cotton results in a soft feel that mimics traditional screen printing while also maintaining the vibrancy and detail expected in modern designs. On the other hand, DTF on polyester and synthetic blends offers incredible color retention and durability, particularly important for items that will experience frequent laundering or wear. This versatility not only helps to expand product lines but also allows for innovative designs that appeal to various market segments.

Ease of Use: Streamlining the Printing Process

DTF transfers are remarkably easy to use, making this method particularly attractive for businesses looking to maximize their production efficiency. With less complicated setup compared to traditional screen printing, operators can quickly learn how to manage the DTF printing system. This ease of use translates to shorter production times and a non-disruptive workflow, allowing companies to fulfill custom orders promptly and effectively.

Moreover, DTF technology can accommodate small production runs efficiently, which is invaluable for businesses that require flexibility in their order sizes. Unlike bulk printing methods that require substantial commitments upfront, DTF enables companies to produce batch quantities that align with customer demand without excessive waste. This efficiency in handling updates to designs or quickly addressing customer requests enhances a business’s agility and responsiveness in the marketplace.

Cost-Effective Solutions with DTF Transfers

In an era where cost efficiency is crucial for small businesses and startups, DTF transfers offer a financially viable alternative to traditional printing methods. The initial investment for DTF technology is lower than many other custom printing options, allowing entrepreneurs to dive into the market without prohibitive overhead costs. This affordable barrier to entry makes it perfect for new designers or small-scale fashion brands looking to explore their creative potential.

Additionally, DTF printing operates on a no-waste principle, aligning perfectly with the needs of those who require custom clothing less frequently. As a result, businesses can take advantage of DTF transfers to produce unique design samples or small runs without incurring significant expenses. This cost-effective printing solution not only encourages experimentation but also supports businesses in maximizing their profits while meeting customer demands.

Frequently Asked Questions

What are DTF transfers and how do they work in DTF printing?

DTF transfers, or Direct to Film transfers, are a printing technique that involves printing designs onto a special film using high-quality inks. The designs are then transferred onto fabrics, such as cotton and polyester, using heat. This method allows for vibrant colors and detailed imagery that adhere well to various materials, making DTF printing a versatile solution for custom apparel.

Can DTF transfers be used on cotton and polyester fabrics?

Yes, DTF transfers are highly versatile and can be applied to a wide range of materials, including DTF on cotton and DTF on polyester. This adaptability makes them suitable for various clothing items, from t-shirts to hoodies, allowing businesses to cater to different customer preferences effectively.

What is the durability of DTF transfers compared to other printing methods?

The durability of DTF transfers is one of their standout features. Once applied, DTF prints bond well with the fabric, allowing them to resist washing, fading, and abrasion. This ensures that garments maintain their quality over time, making DTF transfers a reliable choice for apparel that endures regular use.

How does the cost-effectiveness of DTF printing benefit small businesses?

DTF printing offers cost-effective printing solutions, particularly for small production runs. Unlike traditional methods that may require high setup costs, DTF transfers allow small businesses to produce customized items without significant upfront investment, enabling them to test designs and meet customer demand efficiently.

Is DTF printing a complex process to learn, and what are its advantages?

DTF printing is user-friendly and requires minimal setup compared to methods like screen printing. This simple DTF printing technique allows businesses to execute designs quickly, making it accessible for beginners and facilitating swift turnaround times for custom orders.

What makes DTF transfers a preferred choice over traditional printing methods?

DTF transfers provide numerous benefits, including versatility across various fabrics, high-quality color vibrancy, durability, ease of use, and cost-effectiveness for small runs. These advantages position DTF printing as a modern solution that meets the evolving needs of designers and businesses in the custom printing industry.

| Benefit | Description | Related Keywords |

|---|---|---|

| Versatility in Material | DTF transfers can be applied to a wide range of materials, including cotton, polyester, and blends. | DTF printing, dtf on cotton, dtf on polyester |

| High-Quality Output | Produces vibrant colors and intricate details, suitable for custom designs with fine lines. | DTF printing quality, color vibrancy in DTF |

| Durability | Forms a robust bond with fabrics, resisting washing, fading, and abrasion. | Durability of DTF transfers, DTF prints wash resistance |

| Ease of Use | Requires less setup time and has a short learning curve, enabling quick production. | Simple DTF printing technique, advantages of DTF printing |

| Cost-Effective for Small Runs | Reduces upfront investments and setup costs, beneficial for small businesses and startups. | Cost-effective printing solutions, small batch DTF transfers |

Summary

DTF transfers are revolutionizing the world of custom printing by offering a unique combination of versatility, quality, and cost-effectiveness. From their ability to adhere to various materials to producing high-quality prints that endure through multiple washes, DTF transfers cater to the diverse needs of designers and small businesses. Their simple application process and reduced costs per print, especially for small runs, make them a great choice for entrepreneurs experimenting with design. As the demand for personalized products continues to soar, adopting DTF transfers allows creative individuals to not only meet customer expectations but also to innovate without the burden of excessive costs. Whether you’re looking to start a new project or enhance your current offerings, DTF transfers present a timely solution to elevate your design workflow.