DTF transfers, or Direct to Film transfers, have rapidly become a game-changer in the realm of custom apparel printing. As newcomers and seasoned designers alike explore this innovative method, it’s essential to understand how DTF transfers work and what sets them apart. This cutting-edge technology not only provides stunning visuals but also offers impressive durability and versatility for various fabric types. Dive into our comprehensive DTF printing guide to discover the many benefits, equipment requirements, and best practices that will elevate your printing projects. Whether you’re comparing DTF vs DTG printing or seeking insights into custom apparel printing, this guide is your one-stop resource for mastering the art of DTF transfers.

In the world of fabric customization, Direct to Film technology has emerged as a highly efficient method for achieving striking prints on garments. Often dubbed as the go-to solution for beginners in the creative sector, DTF printing enables users to seamlessly transfer intricate designs onto a wide array of textiles. This versatility makes it an appealing choice for businesses and hobbyists alike, particularly those interested in customized clothing options. By exploring how this transfer technique operates and its widespread benefits, creators can find new opportunities for crafting eye-catching apparel. Ultimately, understanding the nuances between different printing methods, such as DTF and traditional approaches, sets the foundation for successful and engaging product offerings.

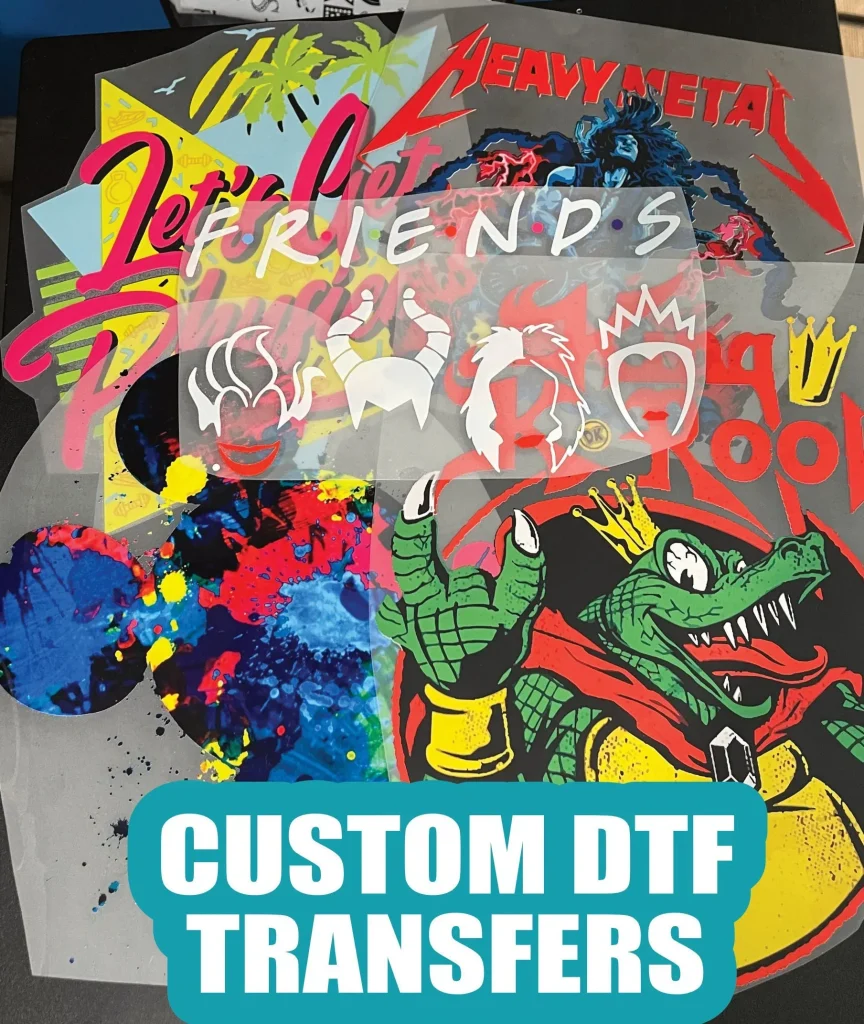

Understanding the Mechanics of DTF Transfers

DTF transfers utilize a unique mechanism that involves several key steps to create beautiful and durable fabric designs. First, a digital image is rendered on a DTF printer using high-quality DTF ink. The image is printed onto a special film, which serves as the medium for the transfer. Once the print is dry, an adhesive powder is dispersed over the image, bonding with the wet ink. This combination is then cured under heat, allowing for a robust adherence between the adhesive and the dye. Following this, the application of heat via a heat press allows the design to transfer seamlessly onto the desired fabric, producing vibrant colors and detailed images.

This multilayer process allows for significant versatility in the types of materials DTF transfers can be applied to, including various fabrics such as cotton, polyester, and blends. Unlike traditional methods such as screen printing or direct-to-garment (DTG) printing, DTF transfers do not require the fabric to be pre-treated, which simplifies the workflow for both amateurs and professionals alike. This additional layer of convenience and quality makes DTF printing an appealing choice within the custom apparel printing industry.

Benefits of Using DTF Transfers for Custom Apparel

The advantages of DTF transfers are numerous, making them an attractive option for businesses and hobbyists alike. One of the most compelling benefits is their unmatched versatility. DTF transfers can adhere to a wide range of fabrics, including cotton, silk, and even neoprene, providing opportunities to create an extensive variety of custom products. This adaptability makes DTF a favorable choice for small businesses aiming to offer diverse and unique items without the restrictions present in other printing techniques.

Another key benefit lies in the durability of the prints produced through DTF technology. Users can expect prints that withstand frequent wash cycles without fading, cracking, or peeling, which is vital for maintaining the quality of apparel over time. This longevity appeals to consumers seeking high-quality, long-lasting custom products, solidifying the interest in DTF printing as a sustainable and reliable method within the competitive landscape of custom apparel.

DTF Compared to DTG Printing: A Side-by-Side Analysis

When considering printing technologies, both DTF and Direct-to-Garment (DTG) techniques offer unique advantages. However, a side-by-side analysis reveals distinct differences that often sway production choices among custom apparel printers. DTF transfers generally allow for more vibrant colors and finer details, as the films used capture intricate designs better than the ink absorption process typical of DTG printing. Additionally, the no-pre-treatment requirement for DTF makes it accessible for beginners who may find DTG’s longer preparation process daunting.

In terms of efficiency, DTF printing can often be faster than DTG, especially in batch orders. The entire printing and application process can be streamlined to fit within a shorter timeframe, which is beneficial for businesses that thrive on quick turnarounds. Thus, while both methods have unique strengths, DTF printing’s combination of speed, quality, and ease of use positions it as a strong contender against DTG for custom apparel printing.

Essential Equipment for Successful DTF Transfer Printing

To master the art of DTF transfers, having the right equipment is non-negotiable. A dedicated DTF printer is crucial; these are specially designed to handle the inks and films used in the process. When selecting a printer, look for models with positive reviews for print quality and reliability. Additionally, don’t underestimate the importance of a high-quality heat press. A premium heat press ensures even distribution of heat and pressure, which is essential for achieving the best adhesion of your designs onto various fabric types.

Furthermore, the adhesive and transfer film play a pivotal role in the DTF process. It’s essential to choose products that are compatible with your printer and inks to guarantee successful transfers. Investing in quality supplies can significantly impact the overall print’s longevity and appearance, allowing users to produce impressive results consistently. In a competitive market where quality matters, equipping yourself correctly is the first step toward DTF transfer success.

Recent Innovations in DTF Technology

Innovation in DTF transfer technology is reshaping the future of custom apparel printing. Recent advancements have introduced printers that not only operate faster but also utilize eco-friendly inks, aligning with the global push towards sustainability. These innovations help reduce the environmental impact associated with traditional printing methods while still maintaining high-quality results. Many new models boast enhanced precision, allowing for greater detail and vibrancy in prints, catering to designer needs seeking intricate and appealing designs.

Moreover, the DTF market has seen significant growth, particularly among small businesses focusing on customization. As technology continues to improve, the demand for DTF transfers is expected to rise, presenting opportunities for those looking to establish or expand their printing ventures. By staying informed on the latest advancements, printers can ensure they are competitive and well-equipped to meet evolving customer needs.

Best Practices for Beginners in DTF Printing

For beginners venturing into DTF transfers, adhering to best practices ensures a smoother learning curve and better results. A solid foundation begins with regular maintenance of your DTF printer. Keeping the print head clean and monitoring ink levels prevents common printing issues that can arise from neglect. Additionally, conducting test prints on various fabrics can aid in understanding how different materials react to the DTF process. Experimentation can uncover which fabrics yield the best results for projects.

Moreover, utilizing the right settings on your DTF printer is crucial to achieving optimal print quality. Familiarize yourself with the software that drives your printer to make necessary adjustments for various designs. Engaging with community forums, online resources, and tutorials can significantly enhance your understanding and proficiency. Through consistent practice and learning, beginners can thrive in the exciting world of DTF transfers and elevate their custom apparel creations.

Frequently Asked Questions

How do DTF transfers work in custom apparel printing?

DTF transfers work by printing a design onto a specialized film using a DTF printer. Once the ink dries, adhesive powder is applied and heat is used to bond the ink to the fabric. This process allows for high-quality, vibrant prints on various materials.

What are the benefits of DTF transfers compared to other printing methods?

DTF transfers offer numerous benefits including versatility across different fabrics, durability against fading and cracking, and ease of use. Unlike DTG printing, DTF does not require pretreatment of fabrics, making it a more accessible option for beginners.

What equipment is required for successful DTF transfers?

To successfully execute DTF transfers, you will need a DTF printer, compatible transfer film and adhesive, and a reliable heat press machine to ensure proper adhesion of the designs to the fabric.

What is the difference between DTF transfers and DTG printing?

The primary difference between DTF transfers and DTG (Direct to Garment) printing lies in their application methods. DTF transfers involve printing designs on film and transferring them with heat, while DTG printing directly prints onto fabric, often requiring pretreatment. DTF is generally more versatile and user-friendly.

How can beginners ensure success with DTF transfers?

Beginners can ensure success with DTF transfers by following best practices such as maintaining their DTF printer, conducting test prints on various fabrics, and utilizing recommended resources like tutorials to refine their techniques.

What recent advancements are being made in DTF transfer technology?

Recent advancements in DTF transfer technology include more efficient printers with enhanced precision and faster printing speeds, as well as the introduction of eco-friendly inks that reduce the environmental impact, making DTF printing a sustainable choice.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | DTF transfers involve printing designs onto a specialized film, applying adhesive, and using heat to bond ink to fabric. This allows for high-quality prints on various materials. |

| Advantages of DTF Transfers | Include versatility, durability, and ease of use, making them perfect for custom apparel printing. |

| Equipment Needed | DTF printers, compatible film, adhesives, and a reliable heat press are essential for DTF printing. |

| Recent Developments | Advancements in technology are leading to enhanced precision, eco-friendly inks, and growing market demand. |

| Best Practices for Beginners | Regular maintenance of printers and conducting test prints on various materials helps ensure quality outcomes. |

Summary

DTF transfers are revolutionizing the world of custom apparel printing, bringing forth a method that is both creative and accessible, particularly for beginners. The process of DTF transfer allows users to produce vibrant, durable prints onto a variety of fabrics, illustrating its versatility and suitability for diverse products. Through the use of specific equipment and adherence to best practices, anyone can successfully create custom designs for personal or professional use. As technology continues to evolve, embracing DTF transfers means entering an exciting realm of possibilities in personalized apparel.