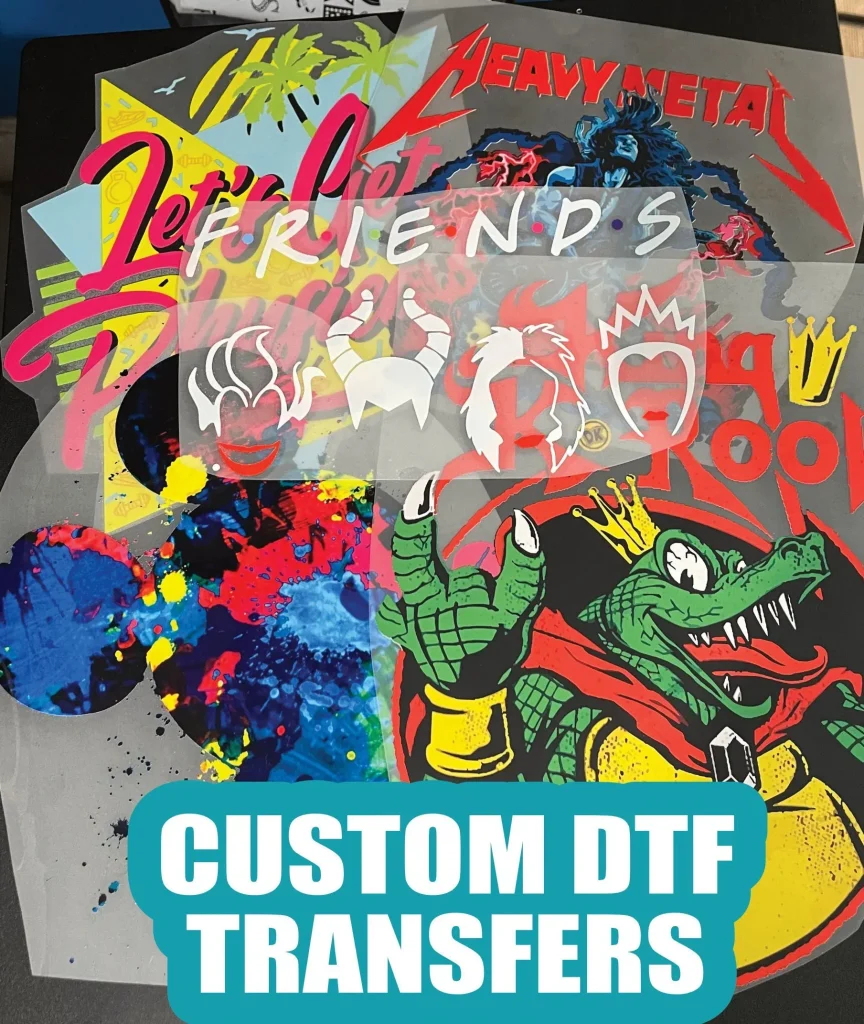

DTF transfers, or Direct to Film printing, have emerged as a revolutionary method in custom apparel printing, captivating businesses with their unmatched versatility and vibrant results. This innovative printing technique simplifies the creation of high-quality designs while ensuring durability that meets customers’ demands. With the DTF printing process, designers can transfer intricate graphics to a variety of fabrics, making it an attractive solution for promotional items and custom garments alike. The advantages of DTF transfers extend beyond just aesthetics; they offer easy production capabilities, allowing small businesses to thrive in a competitive market. As we explore this cutting-edge printing technology, you’ll discover how DTF is setting new standards in the industry.

Direct to Film printing is rapidly changing the landscape of garment decoration, making it a popular choice for those seeking efficient and vibrant printing solutions. Often referred to as DTF, this process involves printing images onto a unique film, which is then transferred to various textiles, including cotton and polyester. DTF transfers provide a plethora of advantages, including durability and versatile application, that appeal to both designers and small business owners in the custom apparel sector. By understanding the DTF printing process, you can appreciate how it stands out compared to traditional methods like DTG (Direct to Garment) printing. As consumer demand for custom designs continues to rise, exploring the nuances of DTF can reveal exciting opportunities for growth in the printing industry.

Understanding the DTF Printing Process

The Direct to Film (DTF) printing process is a revolutionary technique that allows for high-quality designs to be printed onto special transfer films. This method utilizes eco-solvent inks that produce vibrant prints while maintaining flexibility on a variety of fabric types. Designers begin by creating their artwork using sophisticated graphic design tools, ensuring that the design aligns perfectly with the dimensions of the chosen film. This attention to detail is crucial for achieving a stunning final product that resonates with customers.

Once the design is created, it is printed onto the transfer film via specialized DTF printers. This is where the magic of DTF begins; after the print is made, a layer of adhesive powder is applied to the still-wet ink, preparing it for the heat transfer process. The entire operation is streamlined, allowing businesses to produce intricate and colorful designs quickly and efficiently. The result is a product that not only looks good but is also ready for a wide range of applications, from custom apparel to promotional merchandise.

The Versatility of DTF Transfers

One of the standout features of DTF transfers is their unparalleled versatility across various fabric types. Unlike traditional methods that may be limited to specific materials, DTF printing can effectively apply to cotton, polyester, blended fabrics, and more. This adaptability makes it an ideal solution for custom apparel printing, enabling creators to offer a wider range of products, from t-shirts and hoodies to bags and hats. As trends in fashion evolve, businesses can easily pivot their designs to meet customer demands without investing in different printing setups.

Moreover, this versatility extends beyond just fabric types; DTF transfers can manage intricate designs and vibrant color schemes. This capability allows graphic designers to push the boundaries of creativity without worrying about the potential limitations of other printing methods like screen printing or DTG. As a result, the ability to produce bold and complex visual designs not only satisfies customer preferences but also stands out in a competitive marketplace.

Advantages of DTF Transfers Over Other Printing Methods

DTF transfers present several advantages compared to other printing methods such as Direct to Garment (DTG) and screen printing. For starters, DTF printing offers a more cost-effective solution, especially when dealing with smaller production runs. Businesses no longer need to invest significantly in high-cost equipment traditionally required for screen printing. The lower initial investment makes it accessible for small startups and businesses looking to enter the custom printing market.

Another critical advantage is the exceptional durability of DTF prints. Once transferred to the fabric, DTF prints maintain their integrity even after multiple washes, making them an ideal choice for products that see regular use. This stands in contrast to some DTG prints, which may fade or crack under similar circumstances. The combination of vibrant colors, sharp details, and long-lasting results means that customers can count on quality, ideal for building repeat business in the competitive custom apparel market.

The Evolution of DTF Printing Technology

Recent innovations in DTF printing technology have significantly enhanced its efficiency and output quality. With advancements in machinery, manufacturers have improved printing speeds, allowing businesses to produce customized orders at a much faster pace. For companies dealing with high-demand situations or fast fashion, these enhancements to production timelines deliver a strategic advantage.

Additionally, the shift towards eco-friendly practices has led to the development of sustainable inks and improved adhesive formulas, making DTF an even more appealing choice for eco-conscious brands. These innovations not only align with current environmental standards but also offer high-quality results that companies and consumers can trust. DTF printing is paving the way for a future where quality and sustainability go hand in hand.

Comparison: DTF vs. DTG

When comparing DTF printing to Direct to Garment (DTG) printing, the choice often hinges on specific needs such as print volume and design complexity. DTG excels in printing full-color graphics directly on garments, which appeals to businesses focusing solely on fabric applications. However, DTF’s flexibility allows it to be utilized on a broader spectrum of materials, encompassing not just textiles but also promotional items. This capability makes it an invaluable tool for businesses looking to diversify their product offerings.

Furthermore, the startup costs associated with DTF printing tend to be lower than those required for DTG. Businesses can often start with minimal investments and not face the steep learning curves typically seen with DTG printers. This accessibility opens doors for entrepreneurs and small businesses aiming to enter the custom printing industry, making DTF a much more practical choice for many.

Challenges Faced in DTF Printing

While DTF printing offers numerous benefits, it is essential to acknowledge the challenges that come with it. One significant hurdle is the requirement for regular maintenance of the specialized equipment. Like any advanced printing technology, a commitment to routine care is necessary to ensure consistent quality and performance. Businesses need to be prepared for the technical demands of running a DTF printer, which may involve a learning curve particularly for those new to the industry.

In addition to maintenance concerns, achieving consistent print quality can sometimes be a challenge. Factors such as ink settings, printing speed, and heat temperature all play crucial roles in the quality of the final print. Mastery over these variables requires practice and knowledge, as even minor adjustments can lead to variations in output. Therefore, it’s vital that operators invest time in honing their skills to achieve the best results possible.

Frequently Asked Questions

What is DTF Transfers and how does it work?

DTF Transfers, or Direct to Film Transfers, involve a printing process where high-quality images are printed onto a special film using eco-solvent inks. The printed film then has an adhesive powder applied to it, which is heat pressed to bond the design to various fabrics, resulting in vibrant and durable custom apparel.

What are the advantages of using DTF Transfers for custom apparel?

The advantages of DTF Transfers include versatility across fabric types, vibrant color reproduction, durability against washing, and ease of production. This method is particularly beneficial for custom apparel as it allows for detailed designs that last longer than traditional printing methods.

How does DTF Transfers compare to DTG printing?

DTF Transfers differ from DTG (Direct to Garment) printing primarily in cost and versatility. DTF is often more economical, especially for small runs, and can be applied to a wider range of fabrics, including dark textiles, whereas DTG focuses on direct fabric application.

Can DTF Transfers be used on all fabric types?

Yes, DTF Transfers can be applied to a variety of fabric types, including cotton, polyester, and blends. This versatility makes them suitable for diverse applications in custom apparel and promotional items.

What innovations are currently shaping the future of DTF Transfers?

Recent innovations in DTF Transfers include advancements in printing speeds, eco-friendly ink formulations, and improved adhesive technologies that enhance print durability and application on various fabric types.

What challenges do businesses face when using DTF Transfers?

While DTF Transfers offer many benefits, challenges include the need for regular equipment maintenance and a learning curve associated with mastering the printing process. Ensuring consistent quality also requires practice and thorough understanding of materials and settings.

| Key Point | Description |

|---|---|

| Introduction to DTF Transfers | DTF printing revolutionizes garment decoration with vibrant and durable prints. |

| What is DTF Printing? | DTF stands for Direct to Film printing, which uses eco-solvent inks to print designs on a special film. |

| How DTF Works | Involves design creation, printing on film, applying adhesive, and heat transfer to fabric. |

| Advantages of DTF Transfers | Versatile, vibrant colors, durable, and easy production process. |

| DTF vs. DTG | DTF is cost-effective for versatility, while DTG prints directly onto fabric. |

| DTF vs. Screen Printing | DTF requires less setup and is ideal for small runs and intricate designs. |

| Innovations in DTF | Advancements include faster speeds, eco-friendly inks, and improved adhesives. |

| Challenges | Equipment maintenance and mastering the transfer process can be challenging. |

| Future of DTF Transfers | Growing demand for personalization and sustainability will drive DTF printing forward. |

Summary

DTF transfers have emerged as a revolutionary solution for custom garment printing, offering numerous advantages that elevate them above traditional printing methods. With their versatility and ability to produce vibrant, long-lasting designs, DTF Printing not only meets the growing consumer demand for personalized apparel but also stands as a cost-effective option for businesses. As innovations continue to shape this field, we expect DTF transfers to play a pivotal role in the future of the printing industry, promoting both creativity and sustainability in custom apparel decoration.