DTF transfers are rapidly gaining recognition for their revolutionary impact on the world of custom printing. This versatile transfer technology simplifies the process of creating high-quality designs for a wide array of applications, from custom apparel to innovative home decor printing. Enthusiasts and businesses alike are embracing DTF printing applications due to their ease of use, vibrant colors, and durability, making them perfect for DIY projects with DTF. The ability to apply intricate designs with precision opens up new creative avenues, allowing users to personalize their styles effortlessly. As DTF transfers continue to evolve, they are undoubtedly redefining how we approach customization in today’s market.

Direct to Film (DTF) transfer technology stands out as a cutting-edge solution for those wishing to enhance their creative projects. Through this innovative printing approach, individuals can produce not only bespoke apparel items but also striking designs for home decor purposes. The appeal of DTF goes beyond mere functionality; it presents an exciting opportunity for DIY fans to experiment with various materials and artistic expressions. This advanced transfer method is reshaping the landscape of personalized printing, making it accessible to a wide range of users. As the popularity of DTF continues to soar, we can expect to see a growing number of inventive applications and unique design creations.

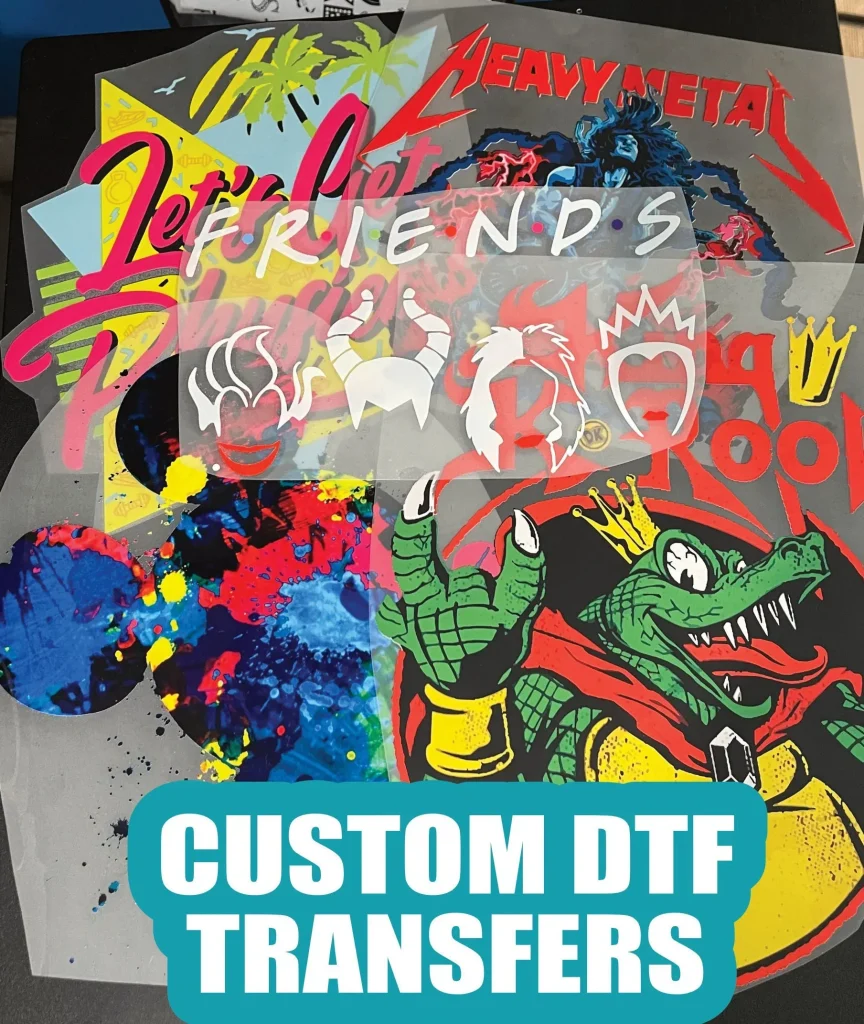

Understanding the Basics of DTF Transfers

DTF transfers, or Direct to Film transfers, are a specialized printing technology designed to produce high-quality, vibrant prints on various materials. This process involves printing designs onto a film using eco-solvent ink, which is then transferred onto the target substrate using heat and pressure. The unique capability of DTF transfers allows for intricate designs to be printed with remarkable detail, making them ideal for both personal and commercial use. As the popularity of custom printing increases, DTF technology stands out for its efficiency and versatility.

The appeal of DTF transfers extends beyond just the printing process. They provide users with the ability to create custom apparel, home decor items, and even personalized gifts. This technology has become an excellent choice for DIY projects, allowing hobbyists to express their creativity while ensuring high-quality results. The ease of use and affordability have contributed to the growing trend of utilizing DTF transfers for various applications.

Diverse Applications of DTF Transfers

DTF transfers have transformed the landscape of custom printing, particularly in the realm of apparel. The ability to print vivid designs on fabrics means that individuals can create personalized clothing that reflects their unique style. From T-shirts to jackets, DTF transfers enable users to design everything from trendy graphic tees to intricate artistic styles. This versatility makes DTF an attractive option for small business owners and entrepreneurs looking to enter the custom apparel market.

In addition to clothing, DTF transfers have found significant applications in home decor. Craft enthusiasts use this technology to create wall art, decorative pillows, and other personalized items that bring a unique touch to their living spaces. With DTF, the only limit is the imagination, allowing for a broad spectrum of creativity in home decor projects. This capability to print on various surfaces, including wood and canvas, enhances the potential for unique, customizable home decorations.

The Rise of DTF in Custom Apparel

As more consumers seek personalized clothing, DTF transfers have become a go-to solution for custom apparel printing. This technology allows for rapid production without the constraints of minimum order requirements, making it accessible to both individual creators and larger brands. Businesses can offer unique designs that cater to niche markets, further solidifying DTF transfers as a viable option in the competitive custom apparel landscape.

Moreover, DTF transfers’ ability to produce high-quality prints ensures that the final products not only look good but also withstand the test of time. This durability appeals to customers who desire clothing that maintains its vibrant colors and intricate designs even after multiple washes. By leveraging DTF technology, custom apparel businesses can provide quality products that satisfy consumer demands.

DIY Projects Using DTF Transfers

The DTF transfer technology has ignited a wave of interest among DIY enthusiasts looking to elevate their projects. The simplicity of the DTF process makes it perfect for crafting personalized items at home, whether it’s a stylish T-shirt for a family gathering or custom artwork for a loved one’s birthday. Instructions and materials are readily available, making it an accessible choice for anyone interested in crafting unique pieces.

Crafting with DTF transfers allows for endless creativity, letting users experiment with various designs and substrates. For instance, crafters can create custom tote bags, hats, and even seasonal decorations, effectively giving them an outlet to showcase their creativity. This versatility in design possibilities is one of the key reasons why DTF printing has become so popular among hobbyists and makers.

Environmental Benefits of DTF Transfers

As sustainability grows in importance, DTF transfers are being recognized for their environmentally friendly qualities. Unlike traditional printing methods that may rely on harmful chemicals or produce wasteful by-products, DTF technology promotes a more sustainable approach. With the ability to create temporary designs that can be easily removed or replaced, users can refresh their printed items without generating unnecessary waste.

This temporary application is particularly relevant in today’s eco-conscious climate, as consumers look for ways to reduce their environmental impact. By opting for DTF transfers in their projects, individuals can maintain a stylish, updated look while minimizing waste—an appealing proposition for those who are mindful of their ecological footprint.

Future Trends in DTF Printing

The future of DTF printing is bright, with ongoing innovations ensuring that this technology remains at the forefront of custom printing solutions. As more companies invest in advancements, we can expect improvements in print quality, durability, and overall efficiency. Emerging trends may include new eco-friendly inks and improved printing machines that expand the capabilities of DTF transfers, making them even more versatile.

As the demand for personalized products continues to rise, creative entrepreneurs and established businesses alike are rushing to adopt DTF technology. This trend leads to a competitive marketplace, stimulating creativity and inspiring new applications in both custom apparel and decor. With a promising trajectory ahead, DTF transfers are likely to become an essential tool for creators across various industries.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, work by printing high-quality designs onto a special film that is then heat-pressed onto various substrates. This versatile transfer technology allows custom prints on fabrics, wood, and other surfaces, making it ideal for both apparel and home decor.

Can DTF transfers be used for DIY projects?

Absolutely! DTF transfers are perfect for DIY projects, allowing you to create personalized items such as custom apparel, wall art, or decorative pillows. Their versatility makes them a popular choice for craft enthusiasts looking to explore their creativity.

How durable are DTF transfers compared to traditional printing methods?

DTF transfers are known for their durability, often outperforming traditional printing methods like screen printing. They can withstand multiple washes and regular wear, ensuring that your custom apparel and home decor designs remain vibrant and intact over time.

What materials can I use DTF transfers on?

DTF transfers can be applied to a wide range of materials, including cotton, polyester, canvas, and wood. This versatility makes DTF technology a favorite for both custom apparel and home decor printing projects.

Are DTF prints easy to remove if I want to change designs?

Yes, one of the benefits of DTF prints is their removability. Users can easily peel off the transfers without damaging the underlying material, allowing for updates or changes without the commitment associated with traditional printing methods.

What advantages do DTF transfers offer for custom apparel businesses?

DTF transfers provide custom apparel businesses with several advantages, including high-resolution prints, vibrant colors, quick turnaround times, and no minimum order requirements. This flexibility helps businesses cater to diverse customer needs while maintaining quality.

| Key Point | Details |

|---|---|

| What is DTF Transfer? | DTF transfer technology enables high-quality prints on various substrates, offering advantages like vibrant colors and detailed designs. |

| Emergence of Premium Services | Companies like Sam’s DTF Transfers provide fast, no-minimum printing, catering to both small businesses and larger brands. |

| Innovative Products | Insta Graphic Systems launched the Insta DTF heat transfer for superior durability and vibrancy in prints. |

| Versatility in Applications | DTF transfers are effective for various applications beyond apparel, including home decor and DIY crafts. |

| Durability | DTF prints are resistant to wear and washing, with removable options that promote sustainability. |

Summary

DTF transfers are transforming the custom printing industry with their unmatched versatility. From creating custom t-shirts to personalizing home decor items, DTF technology offers users a wide range of applications. Companies at the forefront, like Sam’s DTF Transfers and Insta Graphic Systems, are pushing the limits of what’s possible with premium services and innovative products. This adaptability, combined with durability and ease of use, makes DTF transfers a standout choice for both individuals and businesses seeking creative expression. As interest continues to grow, we can expect to see even more exciting developments in the future of custom printing.