In the realm of custom apparel, achieving flawless designs is essential to standing out, and this is where DTF transfers shine. DTF, or Direct to Film printing, revolutionizes how designs are applied to fabrics, producing vibrant prints that captivate audiences. As this innovative technique gains traction among designers and businesses alike, it becomes increasingly clear how valuable DTF transfers are for creating eye-catching apparel. This blog post will guide you through the intricate process of utilizing DTF technology to achieve stunning and durable designs. Get ready to explore essential tips, ensuring that your creations not only look great but also stand the test of time.

When it comes to customizing clothing, direct-to-film technology, commonly referred to as DTF printing, offers remarkable possibilities for artists and entrepreneurs alike. This cutting-edge method utilizes special films to transfer intricately designed artwork onto a variety of fabric types, resulting in eye-popping colors and long-lasting images. Manufacturers and graphic designers embrace DTF transfers for their ability to facilitate vibrant prints, elevating custom apparel to new heights. In this discussion, we will delve into the nuances of the DTF printing process, unveiling design strategies and helpful tips for maximizing print quality. Whether you’re new to fabric printing or looking to refine your skills, understanding the art of DTF will empower you to create designs that truly shine.

Understanding DTF Transfers: The Future of Custom Apparel

Direct to Film (DTF) transfers represent a revolutionary advancement in the custom apparel sector. This innovative printing method allows designers to produce exceptionally vibrant prints that are not only visually appealing but also durable and long-lasting. Unlike traditional printing techniques, DTF utilizes a specialized film to transfer detailed images onto fabric, providing a solution that meets the needs of both small ventures and larger apparel manufacturing operations.

The DTF process showcases versatility across various fabric types, allowing designers to experiment with cotton, polyester, and blended materials. In doing so, they can achieve the optimal balance between comfort and print quality. This adaptability has made DTF printing increasingly popular among fashion designers looking to create unique, personalized clothing items that stand out in a crowded market.

Key Benefits of DTF Transfers for Designing Apparel

The DTF transfer process boasts numerous benefits that enhance the overall design experience for custom apparel creators. One primary advantage is the ability to achieve vibrant colors that vividly reproduce intricate designs, setting DTF apart from traditional printing methods. High-quality inks are specially formulated for DTF, resulting in eye-catching designs that remain true to the original artwork.

Moreover, DTF transfers excel in durability. When applied correctly, the prints resist fading, cracking, and peeling, making them a practical choice for garments that will undergo repeated washing and wear. This resilience enhances the lifetime value of the apparel, pleasing customers and allowing designers to offer products that retain their vibrancy and integrity over time.

Essential Design Preparation Tips for Flawless Transfers

Preparing your designs accurately is crucial for achieving flawless DTF transfers. Start by ensuring that all graphics are of high resolution—at least 300 DPI—to prevent pixelation during the transfer process. Using low-resolution images can lead to unsatisfactory print quality, undermining the vibrancy and detail that DTF is known for. Clever design work that incorporates higher resolutions helps showcase the potential of DTF printing.

Another critical factor in design preparation is color mode selection. Opting for CMYK color mode rather than RGB significantly enhances color accuracy for prints. This conversion ensures that colors appear consistent and true to the original design once transferred to fabric, securing a successful print outcome.

Selecting the Right Fabrics for DTF Transfers

Choosing appropriate fabrics is vital for ensuring the success of DTF transfers. Ideal materials include cotton and polyester, as these options yield stunning results with vibrant color reproduction and excellent fabric adherence. Cotton is a favorite due to its natural softness and breathability, while polyester enhances color brightness during the printing process.

Fabrics with incompatible characteristics, such as certain blends or nylon, should be avoided, as they can hinder adhesion and result in subpar prints. Therefore, understanding the properties of different materials allows designers to make informed choices, leading to higher-quality finished products.

Mastering the Printing and Transfer Process

The printing phase is where your design begins to take shape as a physical product. It’s essential to utilize high-quality inks that are tailored for DTF printing, as the right inks provide better adhesion and longevity for the design. Regular printer maintenance, including cleaning and calibration, guarantees consistent color output and minimizes potential printing errors.

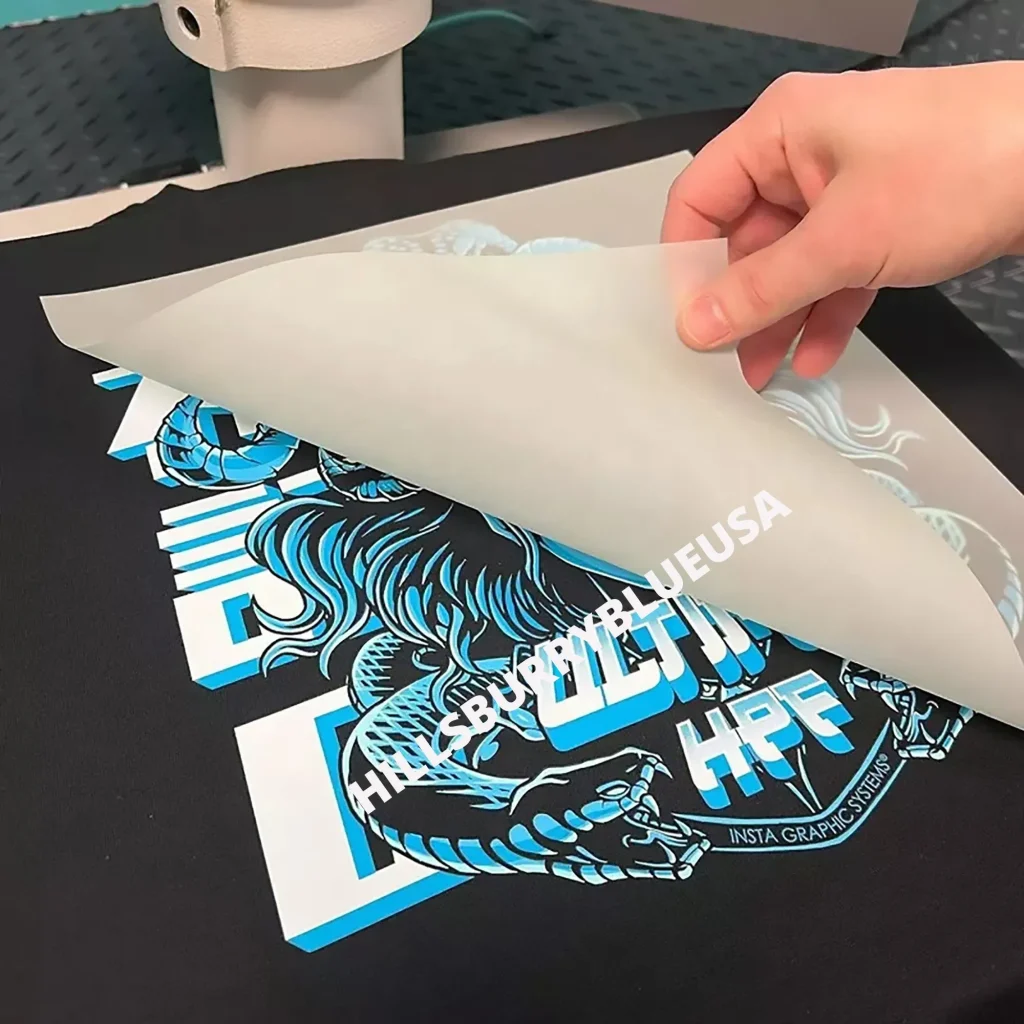

Once your design is printed on the film, the transfer process is the next critical step. Achieving the right temperature and pressure settings is key; ensuring these parameters are maintained according to manufacturer’s specifications leads to an effective bond between the design and the fabric. Proper technique during this phase will significantly enhance the quality of the final apparel.

Post-Application Care and Maintenance

After completing the transfer, proper care is vital for sustaining the high quality of your DTF design. Allowing the garment to cool before peeling off the transfer film enhances adhesion, ensuring the vibrant prints remain intact during washing. This crucial step can significantly affect the longevity of the design.

Additionally, adhering strictly to the washing and care instructions provided by the manufacturer helps maintain the appearance of the print throughout its lifespan. Implementing these guidelines will not only preserve the vibrancy of the colors but also prevent issues like fading or cracking, ensuring that your custom apparel remains as fresh as the day it was printed.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

DTF transfers, or Direct to Film transfers, are a printing method where designs are printed onto a special film that is then transferred to fabric using heat and pressure. This technique allows for the creation of vibrant prints and intricate designs on various apparel materials, making it a popular choice in the custom apparel industry.

What are some design tips for DTF transfers to achieve flawless designs?

To achieve flawless designs with DTF transfers, ensure your graphics are high-resolution (at least 300 DPI) and use the CMYK color mode for accurate color reproduction. It’s also beneficial to simplify complex images to ensure they transfer well and maintain their vibrancy.

Why are vibrant prints important in DTF transfer printing?

Vibrant prints are crucial in DTF transfer printing because they enhance the visual appeal of custom apparel. The quality of inks used in DTF printing produces bright, eye-catching designs that stand out, making them desirable for consumers seeking unique clothing options.

What materials are best suited for DTF transfers?

The best materials for DTF transfers include cotton, polyester, and cotton-polyester blends. These fabrics adhere well to the transfer and support high-quality prints, while materials like nylon may not hold the DTF transfer effectively.

How can I ensure durability in my DTF transfer prints?

To ensure the durability of DTF transfer prints, utilize high-quality inks designed for DTF applications, maintain printer calibration, and follow the correct temperature and pressure settings during the transfer process. Additionally, proper post-application care, such as following washing instructions, will help maintain the print’s vibrancy.

What are some common pitfalls to avoid when using DTF technology?

Common pitfalls when using DTF technology include using low-resolution images, neglecting printer maintenance, and failing to pre-heat the garment before transfer. Additionally, choose compatible fabrics and avoid complex designs for the best transfer results.

| Key Point | Description |

|---|---|

| DTF Transfers | Method for creating vibrant and durable prints on apparel. |

| Versatility | Can be applied to various fabrics like cotton and polyester. |

| Color Reproduction | Uses CMYK color mode for accurate results. |

| Durability | Produces long-lasting prints that resist fading. |

| Design Preparation | Emphasizes high-resolution graphics and compatibility. |

| Pre-Application Steps | Includes printer calibration and material selection. |

| Transfer Process | Involves applying heat and pressure correctly. |

| Post-Application Care | Encompasses cooling and appropriate washing instructions. |

Summary

DTF transfers are revolutionizing the custom apparel industry by allowing for the creation of high-quality, vibrant designs that stand the test of time. When mastering the DTF transfer process, it’s crucial to understand the importance of each step—from design preparation to post-application care. By utilizing top-notch materials, following the correct printing and transfer techniques, and providing proper care for your finished products, you can achieve stunning, long-lasting designs that will captivate your audience. Embrace DTF transfers in your printing projects to elevate your designs and enhance your brand’s presence.