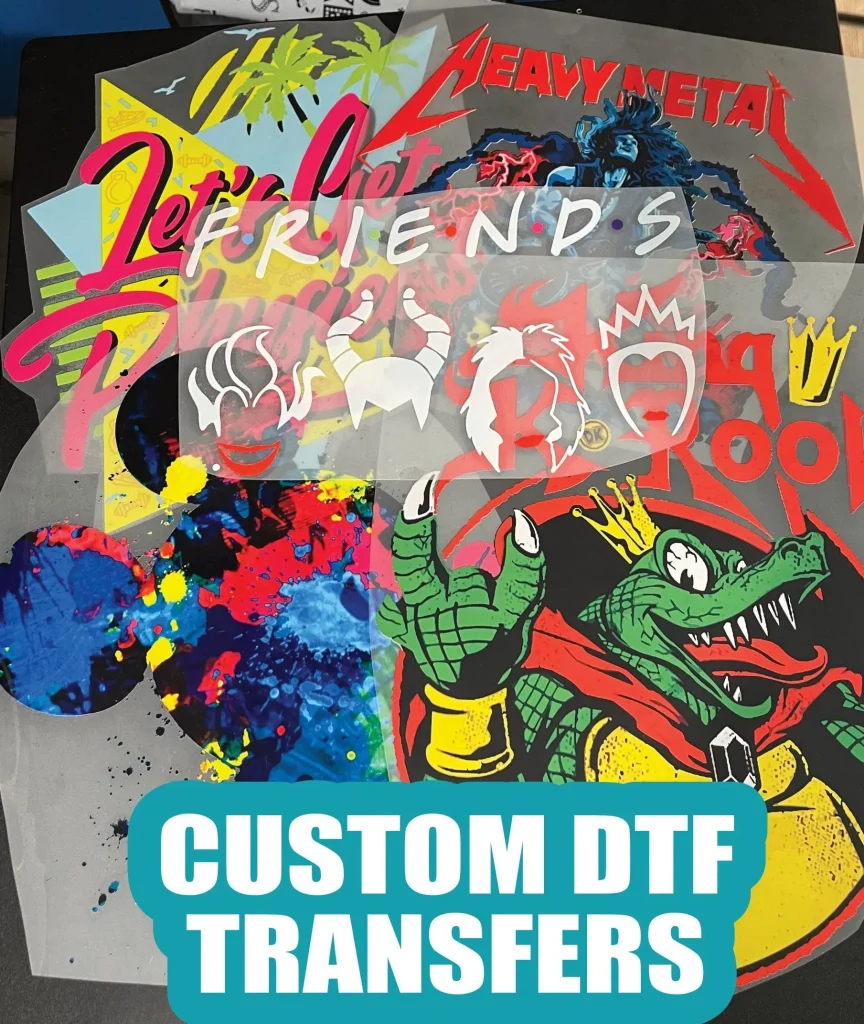

DTF transfers, or Direct-to-Film transfers, are rapidly gaining recognition as a game-changing technology in the world of garment printing. Unlike traditional methods such as screen printing and Direct-to-Garment (DTG) printing, DTF printing combines quality and efficiency while catering to the unique needs of custom apparel businesses. This innovative technique uses advanced printing on a film that seamlessly transfers vibrant images onto various fabrics, making it an ideal choice for both small runs and larger production needs. The benefits of DTF printing extend beyond just versatility; they also offer durability, ensuring that printed designs maintain their vibrancy after multiple washes. With its adaptability surpassing that of conventional sublimation printing, DTF transfers represent a compelling option for anyone looking to elevate their printing game.

Direct-to-Film printing, a cutting-edge method in textile customization, is revolutionizing how images are applied to fabrics. By utilizing specialized films to deliver stunning visuals, this technique stands out from other popular garment printing methods such as screen printing and sublimation. The flexibility inherent in DTF transfers allows for flawless application across a wide variety of materials, making it a favored choice for businesses focusing on unique, custom prints. As this technology evolves, many are discovering its efficiency and practicality compared to alternatives like Direct-to-Garment printing. With a focus on high-quality results and adaptable processes, many industry players are turning to this modern printing solution for their custom apparel needs.

Understanding DTF Transfers and Their Processes

Direct-to-Film (DTF) transfers are a modern innovation in the realm of garment printing, which allow for the creation of vivid and durable designs on various fabrics. This method involves the use of specialized films where designs are printed and then transferred onto garments using heat and pressure. One of the significant benefits of DTF is that it effectively combines qualities of traditional methods such as screen printing and Direct-to-Garment (DTG) printing, offering businesses a new, efficient way to produce custom apparel.

DTF printing’s process is relatively straightforward, making it accessible for businesses looking to fulfill custom printing orders without extensive overhead costs. Unlike the labor-intensive setup required for screen printing and the ink limitations seen in DTG, DTF printing streamlines the production phase, which allows for versatility in applications. This makes it an attractive choice for shops that need to offer a wide variety of designs quickly.

Comparing DTF Transfers and Screen Printing

When comparing DTF transfers with traditional screen printing, efficiency here is a leading differentiator. Screen printing shines in high-volume production due to its ability to create multiple copies quickly. However, it can be less efficient for smaller orders due to the necessity of screen setups and color separations. In contrast, DTF printing can handle small-scale orders economically, as it doesn’t require the same initial setup, making the cost per unit more favorable for multi-design jobs.

Additionally, DTF transfers present superior versatility when it comes to fabric compatibility. While screen printing relies on specific inks designed for certain materials, DTF can print on various fabrics, including cotton and polyester, without compromise on quality. This flexibility allows businesses to expand their range of product offerings without worrying about material restrictions commonly faced by screen printing.

Evaluating DTF Transfers vs. Direct-to-Garment Printing

Both DTF transfers and Direct-to-Garment (DTG) printing offer high-quality outputs, but they serve different needs within the custom garment industry. DTG printing is favored for its ability to reproduce full-color, intricate designs, making it ideal for detailed images. However, this method can be cost-prohibitive for larger quantities and may result in longer production times. In contrast, DTF printing offers a faster turnaround while maintaining similar print quality, which is vital for businesses that operate on tight deadlines.

Moreover, DTF printing excels in durability when compared to DTG. DTF prints are designed to withstand multiple washes while remaining vibrant, whereas DTG prints may fade more quickly over time. The extra layer of flexibility and longevity in DTF printing not only enhances the user experience but also adds value to the final product, making it a compelling choice for custom apparel.

DTF Printing Versus Sublimation: A Critical Comparison

The conversation surrounding DTF printing versus sublimation reveals key differences that affect materials and results. Sublimation is limited to synthetic fabrics, primarily polyester, and often requires additional treatments for cotton, which can add to production time and costs. DTF printing, however, is capable of transferring designs onto both synthetic and natural fibers without the need for pre-treatment, giving it a clear edge in versatility.

While sublimation can produce images of exceptional quality, its dependency on fabric color for vibrancy can be restrictive. DTF printing excels in producing bright, high-resolution designs that maintain their color across a wider range of fabric types. This ability to produce consistent results on varying materials enhances its application possibilities, making DTF a more adaptable solution for businesses that cater to diverse customer needs.

Latest Trends in DTF Technology Development

As the demand for DTF printing continues to rise, recent developments in technology are amplifying its capabilities. Innovations in ink formulations and printing machinery are enhancing print quality, which is critical for businesses that aim to produce professional-grade custom apparel. These advancements not only improve the end product but also streamline the production process, leading to higher efficiency and reduced turnaround times.

Furthermore, with the expansion of e-commerce and on-demand printing services, DTF technology positions itself perfectly to meet the growing market demands. Companies embracing this technology are discovering not just a increase in production capabilities but also significant cost savings, enabling them to remain competitive in an ever-evolving marketplace. The future looks bright for DTF printing, as it aligns with the needs of a dynamic retail landscape.

Why DTF Transfers Are Ideal for Custom Apparel Businesses

For custom apparel businesses, the choice of printing method can significantly impact both production costs and customer satisfaction. DTF transfers stand out as an optimal solution due to their ability to deliver high-quality results across a diverse range of products. Their affordability for small runs combined with the ease of use makes them particularly attractive for startups looking to establish themselves in the market.

Additionally, the flexibility to print on various fabric types without sacrificing quality ensures that businesses can meet the unique demands of their clientele. As the industry shifts towards personalized apparel, those using DTF printing can efficiently respond to custom requests while maintaining a high standard. This adaptability not only keeps companies operational but also broadens their potential customer base as they can cater to a wider array of fabric choices and styles.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a modern garment printing method that involves printing designs on a specialized film which are then transferred onto fabrics using heat and pressure. This technique allows for vibrant, high-quality prints suitable for a variety of materials.

How do DTF transfers compare to screen printing?

DTF transfers provide greater efficiency for small print runs compared to screen printing, which requires extensive setup and is more cost-effective for larger orders. Additionally, DTF can print on a wider range of fabrics without the limitations of specific inks required in screen printing.

Are DTF transfers better than Direct-to-Garment (DTG) printing?

While DTG printing excels in detailed full-color designs, DTF transfers offer quicker production times and often lower costs for larger batches. DTF prints are also known for their durability and softer finish, making them a strong competitor in garment printing.

What advantages do DTF printing benefits offer over sublimation printing?

DTF printing benefits include the ability to print on both synthetic and natural fabrics without pre-treatment, unlike sublimation that primarily works on polyester. Furthermore, DTF can produce bright designs on various fabric colors, showcasing more versatility than sublimation.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers are applicable to a diverse range of fabrics including cotton, polyester, and blends, offering versatility that is not common in traditional methods like screen printing which often require specific inks for certain materials.

What is driving the popularity of DTF transfers in the printing industry?

The rising demand for custom apparel, along with the efficiency, quality, and affordability of DTF transfers, is driving their popularity. As e-commerce and on-demand printing grow, DTF’s ability to handle small runs and produce quick turnarounds is becoming increasingly valuable for both small and large businesses.

| Comparison | DTF Transfers | Screen Printing | DTG Printing | Sublimation |

|---|---|---|---|---|

| Efficiency | Cost-effective for smaller orders with no extensive setup | Ideal for high-volume orders but less efficient for small runs | Higher costs per print, slower turnaround for smaller runs | Not applicable for natural fabrics, slower for high-quality results |

| Versatility | Adapts to various fabric types (cotton, polyester, blends) | Limited to specific inks for certain fabrics | Excels in full-color details but less versatile in fabric choices | Works best on synthetic fabrics, requires special treatments for cotton |

| Quality | Produces vibrant, detailed prints quickly | Excellent for larger runs, may lack detail in small designs | High-quality, detailed outputs, but more expensive | Amazing photo-quality, but limited by fabric color |

| Durability | Withstands multiple washes while retaining vibrancy | Durable, but detail can fade over time | Durable but can lack the softness of DTF prints | Generally less durable, dependent on fabric used |

| Recent Developments | Ongoing advancements, increasing popularity in custom apparel | Established method; evolution is slower | Technology improving, focus on larger markets | Stable but limited growth targeting specific materials |

Summary

DTF transfers represent a groundbreaking approach in garment printing, combining quality with versatility and cost-effectiveness. As an innovative method that outshines more traditional techniques like screen printing, DTG, and sublimation, DTF transfers are quickly becoming the preferred choice due to their ability to adapt to various fabrics and achieve vibrant prints without compromise. This emerging technology not only meets the demands of smaller orders but also positions itself as a vital tool for businesses aiming for efficiency in today’s fast-paced marketplace. As advancements continue, DTF printing is set to redefine the standards in the textile industry, making it essential for those looking to enhance their product offerings.