In the ever-evolving realm of apparel design, DTF transfers are emerging as a game-changer for artists and entrepreneurs alike. These innovative Direct-to-Film (DTF) transfers enable the creation of stunning, custom apparel with vibrant prints that truly stand out. Harnessing the power of DTF technology, designers can effortlessly apply intricate designs onto fabric, opening a world of creative possibilities. This article delves into how DTF transfers can help you maximize your creative potential and elevate your apparel production. Whether you’re a seasoned professional or just starting, the versatility and quality offered by DTF printing will inspire you to express your unique style like never before.

Direct-to-Film (DTF) printing, often recognized for its cutting-edge approach to transferring designs, is revolutionizing how we personalize and create custom clothing. Often categorized with terms like film transfer printing, this technique employs advanced technology to deliver rich colors and detailed artwork directly onto various fabric types. By using this method, designers can achieve striking visual effects that captivate audiences, making the production of custom apparel more accessible than ever. This article will explore the unique advantages and creative applications of DTF technology, helping you uncover how it can transform your apparel design projects. As demand for personalized and vibrant products rises, DTF printing is set to play a pivotal role in shaping the future of fashion.

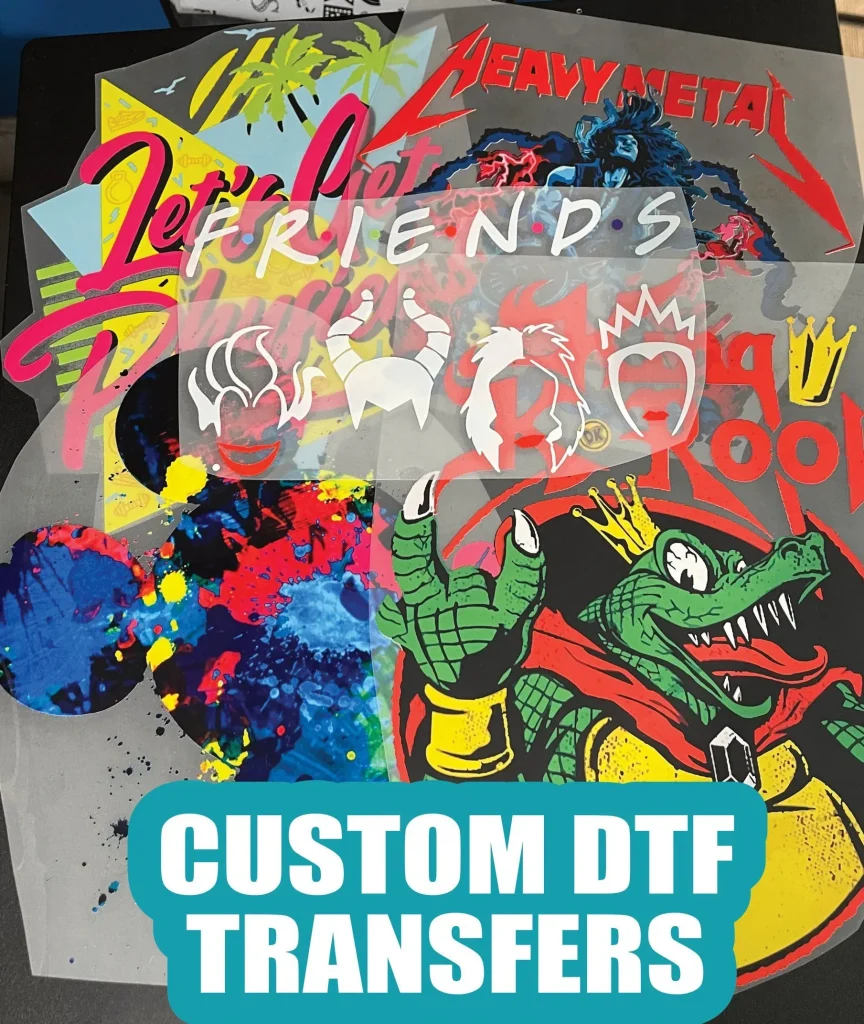

The Power of DTF Transfers in Custom Apparel

DTF transfers are revolutionizing custom apparel, allowing creators to turn their unique designs into wearable art. With this innovative printing technology, artists can produce vibrant prints that truly reflect their style. The ability to transfer intricate designs onto various fabric types means that shirts, hoodies, and other clothing items can be customized with ease, meeting the increasing consumer demand for personalized products. Additionally, DTF allows for larger designs to be printed with less risk of color changes or fading, making it ideal for fashion-forward businesses looking to stand out.

Moreover, DTF technology enhances the opportunity for small business owners and independent creators to enter the custom apparel market without the heavy financial burden associated with traditional early-in technology. They can experiment with a wide range of materials—from cotton to blends—easily adapting their creations for numerous applications. As the customization trend continues to rise, DTF transfers provide an accessible entry point for anyone looking to enhance their apparel production capabilities.

Innovative Techniques for Effective DTF Transfers

To maximize the impact of DTF technology, utilizing design software is essential for creating effective visual graphics. Programs like Adobe Illustrator or CorelDRAW help designers generate high-resolution images tailored for the DTF process. This leads to crisp, eye-catching prints that capture attention and allow for creativity to shine through. Coupling high-quality designs with the right materials, including premium transfer films and inks, ensures that final products are not only vibrant but also durable, standing the test of time against wear and tear.

Experimentation is key when mastering DTF transfers. Creators should feel encouraged to mix various colors, patterns, and materials to find their distinctive style. Each trial can bring valuable insights into what works best for their brand, as success often follows a process of continuous modification and improvement. Sharing these experiments within creative communities can also provide additional inspiration and feedback, fostering an environment for collective growth and innovation in apparel design.

Diverse Applications Beyond Apparel

While DTF transfers are well-known for their application in custom apparel, their versatility extends far into other product categories. The technology allows for the creation of bespoke home decor items, such as throw pillows and wall art, adding a personalized touch to living spaces. This can be particularly appealing for designers looking to branch out into lifestyle products that harmonize with modern consumer interests in unique home aesthetics.

Accessories represent another exciting frontier for DTF applications. Items like tote bags, caps, and phone cases can be adorned with custom prints that resonate with niche audiences. The market for accessories is increasingly driven by consumers seeking personalized and limited-edition products, making DTF technology a valuable tool for tapping into this demand. By expanding beyond traditional clothing, creators can leverage DTF to diversify their product offerings and connect with broader segments of the market.

Best Practices to Maximize DTF Printing Quality

To ensure the highest quality results from DTF printing, it is crucial to adopt certain best practices. Firstly, selecting top-tier materials is non-negotiable; high-quality films and inks directly impact the vibrancy and longevity of prints. Investing in excellent supplies can help prevent common printing issues such as cracking or fading, ultimately leading to more satisfactory outcomes for customers.

Another key consideration is the preparation of design files for printing. High-resolution images are vital for capturing intricate details and delivering professional results. Utilizing a suitable color profile that aligns with the DTF printing process can enhance the accuracy of prints, ensuring that the final product closely resembles the intended design. By adhering to these best practices, creators can confidently produce vibrant, high-quality prints that appeal to consumers in today’s competitive market.

Current Trends in the DTF Transfer Industry

The DTF transfer technology landscape is constantly evolving, with numerous trends shaping its future. Eco-friendly inks are gaining traction, catering to consumers’ desire for sustainable products within the fashion industry. As the demand for environmental responsibility in apparel production grows, businesses adopting eco-conscious inks will likely find an edge in attracting environmentally-minded customers.

Additionally, advancements in DTF printing equipment, such as faster printers and enhanced design capabilities, are streamlining the production process. These improvements not only increase efficiency but also allow creators to experiment with more complex designs and quicker turnaround times. Staying informed about the latest industry innovations and trends can help artists and entrepreneurs remain competitive and relevant in a rapidly shifting market.

Building Community Support for DTF Creators

Engaging with the DTF creator community is invaluable for artists looking to learn from others and share insights. Online forums, social media groups, and dedicated blogs provide platforms for creatives to share their experiences, troubleshoot pressing issues, and inspire each other in their journeys. By actively participating in these communities, artists can gain access to a wealth of knowledge and resources, greatly benefitting their craft and business.

Support networks also encourage collaboration and idea-sharing that help spark innovation. Whether someone is seeking advice on design software or best practices for printing, the camaraderie found within these communities fosters a culture of support that can elevate the quality of DTF printed products. Networking with like-minded individuals can also lead to potential partnerships, expanding creative horizons and opening new avenues for business development.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing method that involves printing high-quality designs onto a special film using vibrant inks. The printed film is then heat-pressed onto fabric, creating durable and vivid designs without the need for pretreating fabrics, unlike Direct-to-Garment printing.

What materials can I use for DTF transfer printing?

DTF transfer technology is highly versatile and can be used on various materials, including cotton, polyester, and blended fabrics. This flexibility allows artists and designers to create custom apparel and products that suit diverse applications, from t-shirts to home decor.

How can I maximize the quality of my DTF transfers?

To maximize the quality of your DTF transfers, use high-resolution design files, select premium quality films and inks, and ensure your printing equipment is properly calibrated. Investing in quality materials will reduce issues like fading, cracking, and peeling, ensuring long-lasting vibrant prints.

What are the creative applications of DTF transfers?

DTF transfers can be applied creatively across different products, including custom apparel like t-shirts and hoodies, home decor items such as throw pillows, and accessories like hats and bags. This versatility allows creators to express their unique style in various ways.

Are there any best practices I should follow for DTF printing?

Yes, some best practices for DTF printing include utilizing design software like Adobe Illustrator, choosing high-quality materials to ensure durability, and experimenting with diverse designs and fabrics. Trial and error can help refine your artistic style and optimize results.

How does DTF technology compare to other printing methods?

DTF technology offers several advantages over traditional printing methods like Direct-to-Garment and screen printing. It allows for vibrant color outputs, requires no fabric pretreatment, and can easily handle intricate designs, making it ideal for custom apparel and fostering creativity.

| Aspect | Details |

|---|---|

| Introduction | Explore DTF transfers as a medium for creative expression and product uniqueness. |

| Understanding DTF Transfers | DTF transfers involve printing designs onto film that can be transferred to fabric without pretreatment, allowing flexibility with different materials. |

| Benefits | DTF transfers allow intricate designs, cater to the growing customization demand, and are cost-effective for small businesses. |

| Creative Applications | Includes custom apparel, home decor, and accessories that express individual artistry. |

| Best Practices | Utilize high-quality design software, select premium materials, and engage in experimentation to refine designs. |

| Industry Insights | Emerging technologies and community resources are shaping DTF printing, leading to innovative designs and eco-friendly practices. |

Summary

DTF transfers serve as a groundbreaking solution for artists and entrepreneurs looking to make their mark in the design world. By leveraging DTF transfers, you can unlock new opportunities for creative expression, producing everything from custom apparel to unique home decor that reflects your style. This innovative printing technology not only enhances your artistic capabilities but also responds effectively to the rising demand for personalized products in the e-commerce market. Embracing DTF transfers means stepping into a future where creativity knows no bounds, empowering you to turn your visions into vivid realities.