DTF transfers, or Direct-to-Film transfers, have emerged as a groundbreaking technique in the printing industry, revolutionizing the way we approach garment printing and custom creations. This advanced technology allows designs to be printed on a unique film before being transferred onto fabrics, resulting in vibrant colors and intricate details that wow consumers. As more businesses leverage DTF technology, they are discovering the immense potential it holds for efficiency and quality in custom printing solutions. The shift towards DTF transfers is not just a trend but a significant evolution within the printing sector, paving the way for innovative applications and improved product offerings. In this article, we will delve deeper into the myriad benefits of DTF transfers and explore how they are reshaping the landscape of the printing industry.

Also referred to as Direct-to-Film printing, the method of utilizing DTF technology has created a buzz in the realm of custom printing solutions, especially within the garment industry. This innovative approach involves printing designs onto a specialized film that is then used to apply stunning visuals onto a variety of fabrics. As traditional printing methods give way to these advancements, creators and businesses are increasingly turning to DTF transfers to achieve superior results. The versatility and efficiency of this technology not only simplify the production process but also enhance the quality of finished products, making it a game changer for those looking to make their mark in the printing domain. As we explore this topic further, it becomes evident how such innovations can lead to limitless possibilities in creative expression and production.

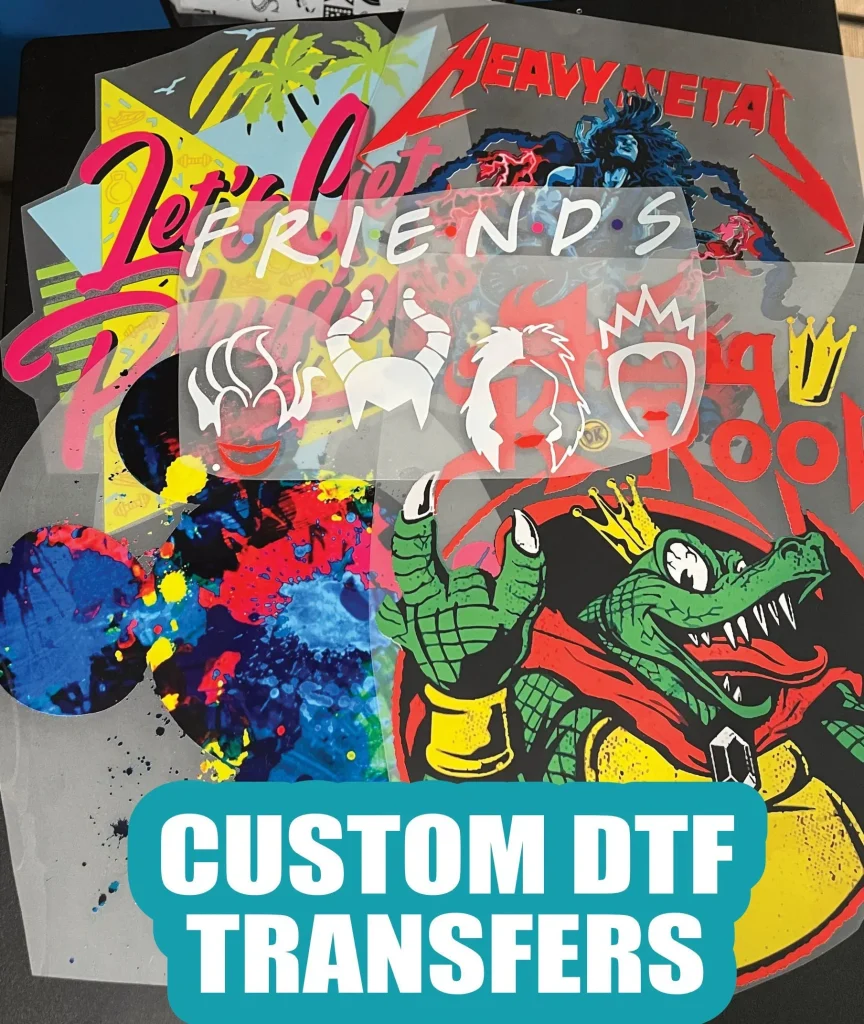

Understanding Direct-to-Film (DTF) Transfers

Direct-to-Film (DTF) transfers represent a significant advancement in the field of garment printing. This innovative technique utilizes a digital printing method combined with specialty films to create high-resolution, vibrant designs. It has become increasingly popular due to its ability to produce detailed artwork with minimal effort compared to traditional silk-screening or direct-to-garment (DTG) methods. DTF technology caters to a wide variety of fabrics, which makes it a versatile choice for both commercial and personal projects.

In essence, the DTF process begins with printing the design onto a film using a DTF printer, followed by applying adhesive and transferring it onto the chosen textile with heat. This method not only allows for more intricate designs but also facilitates the application of prints on fabrics that were previously difficult to work with, such as nylon and polyester blends. As such, DTF transfers are not only a practical solution but also expand the creative possibilities for designers and print businesses.

Key Advantages of DTF Printing Technology

The adoption of DTF printing technology comes with a multitude of benefits that appeal to businesses specializing in custom printing solutions. One of the most prominent advantages is the vivid color reproduction it offers. By using a combination of CMYK and white inks, DTF transfers achieve striking visuals that maintain their intensity even after multiple washes, thus ensuring longevity of prints. This durability makes DTF an economical choice for businesses looking to provide high-quality output without sacrificing cost-effectiveness.

Moreover, the versatility of DTF technology is another major draw for print service providers. Unlike traditional methods restricted to specific fabric types, DTF transfers can be successfully applied to a wide array of materials, including cotton, polyester, and blends. This characteristic broadens the market opportunities for businesses as they can cater to different customer needs, from clothing lines to promotional items.

Innovations Driving DTF Transfer Growth

Recent developments in the DTF printing sector have significantly contributed to its rapid growth. Innovations such as EazyDTF’s recent expansion with additional large-format printers demonstrate the increasing demand for high-capacity DTF services. With the ability to deliver same-day shipping across the nation, EazyDTF is not only optimizing production but also enhancing customer satisfaction by ensuring timely fulfillment of orders.

Similarly, companies like Snuggle have jumped on the DTF bandwagon by launching services capable of producing thousands of DTF transfers daily. Their emphasis on scalability reflects the changing landscape of the printing industry, as businesses look for solutions that can efficiently meet the increasing demand for customized apparel. These advancements underscore DTF technology’s role as a frontrunner in printing industry innovations.

Customized Solutions for Creators and Crafters

The rise of customized solutions in DTF printing has opened new avenues for individual creators and small businesses. Services such as those offered by DTFPrinter, which focus on tailoring DTF transfers for crafters, highlight the growing importance of personalization in the printing industry. By offering high-quality, customizable prints, DTFPrinter confirms its commitment to empowering creators with the tools they need to bring their unique visions to life.

This focus on customization is essential in today’s market, where consumers increasingly seek personalized products that stand out. DTF technology facilitates this demand by allowing for rapid production and easy alterations to designs, perfect for small-scale creators desiring flexibility in their work. Consequently, this aspect of DTF printing not only benefits individual entrepreneurs but also elevates customer engagement by providing tailored merchandise.

Educational Initiatives in the DTF Community

Knowledge sharing within the DTF community is crucial for fostering growth and innovation in this printing technique. Recent events like GJS’s webinar series aim to educate both emerging and experienced printers about the latest developments in DTF technology. By providing access to expert insights and practical demonstrations, these events help participants develop new skills and enhance their understanding of the capabilities of DTF transfers.

Moreover, such initiatives encourage collaboration among industry professionals, enabling them to exchange best practices and innovative techniques. As the DTF market expands, these educational opportunities play an essential role in ensuring that businesses can adapt to the evolving demands of their customers and maintain a competitive edge.

Future Trends in DTF Printing and Customization

As DTF technology evolves, future trends indicate an even greater focus on automation and integration within the printing process. Businesses are likely to invest in advanced machinery that enhances productivity while reducing labor costs, ultimately leading to more streamlined workflows. Automation presents a golden opportunity for print service providers to scale their operations efficiently, catering to the increasing market demand without compromising on quality.

Additionally, the move towards eco-friendly materials and sustainable practices is expected to make a significant impact on the DTF printing segment. As consumers become more environmentally conscious, businesses will need to adapt by utilizing sustainable inks and films that align with this green movement. This trend not only benefits the environment but also opens new marketing avenues for businesses looking to attract eco-aware customers.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film that is then heat-transferred onto fabrics. This method allows for vibrant colors and intricate details to be applied to various substrates, making DTF technology a gamechanger in garment printing.

What are the advantages of using DTF technology for garment printing?

DTF technology provides several key benefits for garment printing: it produces vibrant colors due to CMYK and white inks, offers long-lasting durability that withstands washes, and is versatile enough to work on many materials like cotton and polyester. Additionally, the ease of use in the DTF process speeds up production.

How does DTF technology compare to traditional printing methods?

Unlike traditional printing methods that often involve complex and time-consuming setups, DTF transfers simplify the printing process. DTF technology allows for quick and efficient production while delivering high-quality prints, making it a preferred choice among professionals in the printing industry.

Can DTF transfers be used on all types of fabrics?

Yes, DTF transfers are highly versatile and can be applied to a wide range of fabrics including cotton, polyester, and blends. This adaptability makes DTF technology suitable for various custom printing solutions and garment printing needs.

What recent innovations are driving the growth of DTF printing?

Recent innovations in DTF printing include EazyDTF’s expansion with more large-format printers for better service delivery, Snuggle’s high-capacity DTF transfer service for on-demand printing, and DTFPrinter’s tailored offerings for custom printing needs. These advancements are significantly impacting the printing industry’s landscape.

Where can I learn more about DTF technology and its applications?

To learn more about DTF technology and its applications, consider attending industry webinars like GJS’s “Discovering DTF,” which focuses on advancements through product demonstrations. Additionally, exploring resources and services from companies like EazyDTF and Snuggle can provide insights into the latest trends in DTF printing.

| Aspect | Details |

|---|---|

| Overview of DTF Transfers | DTF transfers involve printing designs on a special film and transferring it onto various substrates (mainly fabric) via heat. |

| Benefits | 1. Vibrant Colors: Offers detailed prints through CMYK and white inks. 2. Durability: Designs are long-lasting and withstand multiple washes. 3. Versatility: Compatible with various materials including cotton and polyester. 4. Ease of Use: Streamlined process allows for quicker production. |

| Recent Innovations | 1. EazyDTF’s expansion with new printers for nationwide delivery. 2. Snuggle’s trade service producing large volumes of DTF prints. 3. DTFPrinter’s custom services aimed at crafters. 4. GJS’s webinars promoting knowledge sharing. |

Summary

DTF transfers are at the forefront of technological advancements in the printing industry, offering innovative solutions for high-quality, customizable prints that cater to a wide array of applications. The unique ability of DTF transfers to produce vibrant colors and durable finishes has positioned them as a game-changing alternative to traditional printing methods. With continued investments from major players and the introduction of new services tailored to meet diverse business needs, DTF transfers is proving to be an essential technology for the future of garment printing and custom creations. As businesses adopt these advancements, they open up new opportunities for efficiency and creativity, ensuring that DTF transfers remain a pivotal part of the evolving landscape of the printing industry.