In the ever-evolving landscape of custom apparel design, DTF transfers are revolutionizing how designs come to life on fabric. By utilizing Direct-to-Film (DTF) technology, artists and designers can achieve vibrant, detailed prints that previously seemed unattainable. When compared to traditional screen printing, DTF stands out by offering flexibility, cost-effectiveness for small runs, and a sustainable printing option that aligns with current eco-conscious trends. This innovative method has quickly gained popularity among businesses aiming to create unique and personalized designs efficiently. As we explore the dynamic world of DTF versus screen printing, it becomes essential to understand the profound impact of these advancements on the future of custom design.

When discussing advanced garment printing techniques, many professionals refer to Direct-to-Film (DTF) transfers, a method that offers unparalleled customization in textile printing. Recent shifts towards eco-friendly practices have made DTF an appealing option, particularly as it allows for intricate designs without the waste associated with some traditional methods. Compared to classic methods like screen printing, which can be labor-intensive and limited in color, DTF provides a vibrant, quick, and efficient approach to custom fabric printing. As industries look for the best printing methods to meet consumer demand, sustainable printing options like DTF are becoming integral to the conversation around modern custom apparel solutions.

Understanding DTF Transfers in Custom Apparel

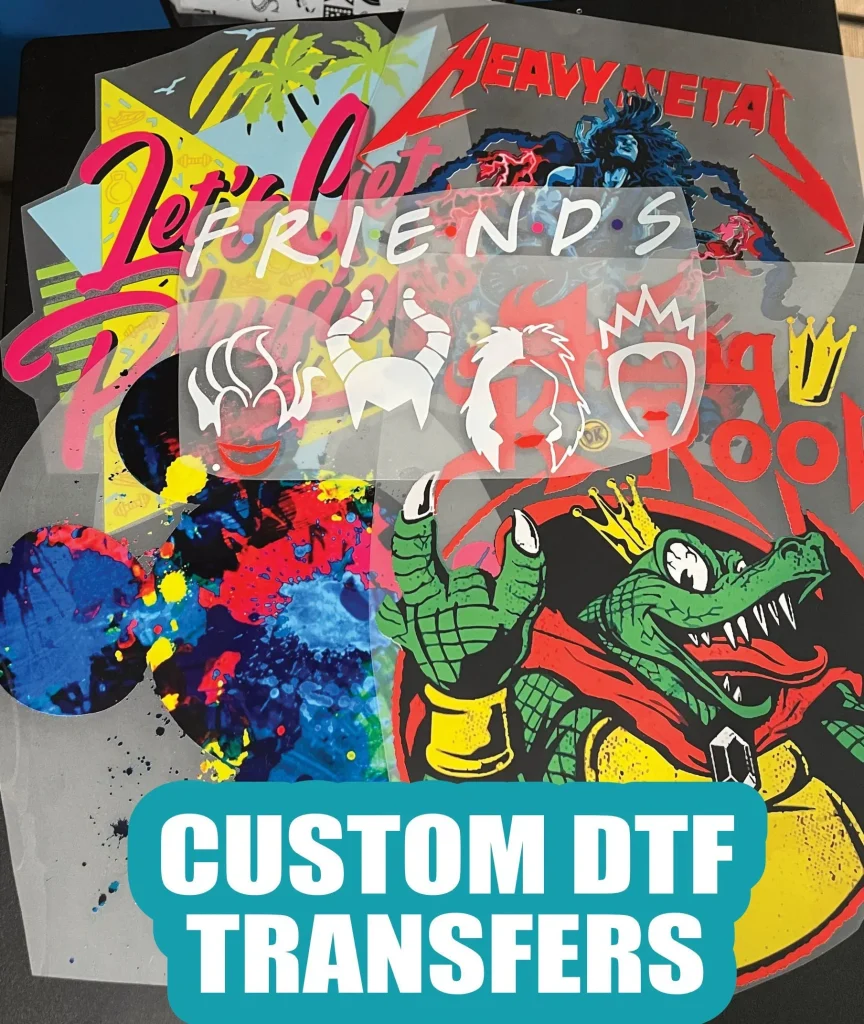

Direct-to-Film (DTF) transfers are revolutionizing the custom apparel design scene by offering an impressive blend of detail and color that traditional screen printing often struggles to match. DTF utilizes advanced printing technology that allows for high-resolution images to be printed directly onto a special film, which can then be transferred onto garments. This method not only enhances the vibrancy of colors but also allows for intricate designs that can captivate consumers. By tapping into this sophisticated technology, designers can easily produce customized apparel that stands out in a crowded marketplace.

In contrast to screen printing, which is notorious for its limitations regarding color and design complexity, DTF transfers break these barriers by providing access to an extensive color palette. Brands seeking to create unique, vivid designs find DTF printing to be a game-changer, allowing them to explore their creativity without compromising on quality. As the demand for personalized apparel rises, understanding DTF technology becomes essential for any designer looking to innovate and stand out.

DTF vs Screen Printing: A Comparative Analysis

When comparing DTF transfers with screen printing, one must consider factors such as setup costs, production times, and the quality of prints. DTF transfers are particularly advantageous for smaller production runs, as they require minimal setup compared to screen printing, which often incurs more costs and labor, especially when color separations and screens must be prepared for each design. This efficiency makes DTF an appealing choice for small businesses and individual designers who are looking to enter the market without the financial burden associated with traditional methods.

Additionally, DTF technology boasts superior image resolution and color matching capabilities, further enhancing its competitive edge against screen printing. As the landscape of custom apparel design shifts toward demand for swift turnaround on smaller quantities, DTF presents a viable alternative, allowing businesses to respond agilely to consumer trends without being hampered by the constraints of screen printing.

Economic Advantages of DTF Transfers for Small Businesses

One of the primary economic advantages of DTF transfers is their cost-effectiveness, especially for small runs and personalized orders. DTF allows for more flexible pricing structures because it eliminates the need for large quantities commonly associated with screen printing. This flexibility directly supports entrepreneurs and small business owners seeking to test the waters of custom apparel design without overcommitting resources to inventory.

In the context of evolving market demands, DTF’s ability to streamline costs can help small businesses maintain healthy margins while delivering high-quality custom designs. This makes DTF an attractive option for startups or businesses focused on niche markets that require unique and personalized products without incurring exorbitant costs.

Sustainability in DTF Printing

Sustainability is more than just a trend; it has become a requirement in modern manufacturing processes, including the custom apparel industry. DTF transfers contribute to this sustainability movement by minimizing waste during production. Unlike traditional screen printing, which often generates significant waste, DTF utilizes a precise application process, ensuring that only the necessary materials are used in the creation of each design.

Moreover, as more consumers prioritize sustainable products, brands that adopt DTF printing can enhance their marketability. Transitioning to eco-friendlier options allows businesses to align themselves with conscientious consumer values, thus attracting a broader customer base and securing a competitive advantage in an increasingly ethical market landscape.

The Role of Technology in Advancing DTF Printing

Recent advancements in DTF technology have significantly impacted the quality and efficiency of custom garment printing. The integration of high-resolution printers and inks formulated specifically for DTF has enhanced the vibrancy and durability of color applications on fabrics. This not only allows for intricate designs but also ensures longevity in product wear, thereby meeting customer expectations for quality.

Moreover, as DTF printing technology continues to evolve, it opens doors for innovative applications that were once thought unattainable. The scalability of DTF printers means that small creators and crafting enthusiasts can explore professional-grade outputs without investing heavily in cumbersome equipment, thus bridging the gap between professional and DIY production.

Future Trends in Custom Printing: The Rise of DTF

Looking ahead, DTF transfers are set to lead the charge in custom apparel design as technology continues to advance and consumer preferences shift toward personalized and sustainable options. With a growing demand for unique, high-quality prints, brands that embrace DTF are likely to thrive in an increasingly competitive market. This trend reflects a broader movement where creativity and eco-consciousness intersect.

As businesses begin to harness the full potential of DTF printing, collaborations with local artists and designers can emerge, further enriching the tapestry of custom apparel offerings. This not only supports local economies but also encourages a diverse range of creative expression within the apparel sector. Ultimately, those who adopt DTF technology will not only stand out creatively but will also reinforce their commitment to sustainable practices.

Frequently Asked Questions

What are DTF Transfers and how do they compare to traditional screen printing?

DTF Transfers, or Direct-to-Film Transfers, are a modern printing technique used for custom apparel design. Unlike traditional screen printing, which relies on stencils and ink layers, DTF printing allows for unlimited color use and high detail in designs. This method also minimizes waste, making it a more sustainable option compared to screen printing.

Why are DTF Transfers considered more cost-effective for small runs than screen printing?

DTF Transfers are cost-effective for small runs because they have lower setup costs and faster processing times. Unlike screen printing, which can be expensive and time-consuming for small quantities, DTF allows businesses to save money and achieve quicker turnarounds on customized orders.

What advantages do DTF Transfers offer in terms of sustainability compared to screen printing?

DTF Transfers are recognized for their sustainable printing options, as they produce less textile waste than traditional screen printing methods. This eco-friendly approach aligns with the growing demand for environmentally responsible practices in the custom apparel industry, making DTF a preferred choice for brands focusing on sustainability.

How does DTF vs screen printing differ in terms of color variety and design detail?

DTF Transfers significantly outperform screen printing when it comes to color variety and design detail. DTF printing allows for an unlimited color palette and maintains vibrant, intricate designs, whereas screen printing is limited to a set number of colors per print run, which can restrict creative expression.

What makes DTF Transfers accessible for small businesses and individual designers?

The accessibility of DTF Transfers stems from the emergence of user-friendly printers designed for at-home crafters and small business owners. This democratization of custom printing technology lowers the barriers to entry for budding designers and encourages creativity within the market.

What future trends can we expect for DTF Transfers in the custom apparel design industry?

The future of DTF Transfers in the custom apparel design industry looks promising, with anticipated advancements in technology and increasing market adoption. As more businesses recognize the benefits of sustainability, detail, and efficiency that DTF printing provides, we can expect an upward trend in its use over traditional screen printing.

| Key Features | DTF Transfers | Screen Printing |

|---|---|---|

| Detail and Color Variety | Unlimited color palette, high vibrancy, and detail are achievable. | Limited color options based on setup; can be less detailed. |

| Cost-Effectiveness | Lower setup costs and faster processing times for small runs. | More suitable for larger production runs; higher costs for small orders. |

| Accessibility | User-friendly DTF printers available for home use; easy entry for new designers. | Requires more equipment and setup; less accessible for beginners. |

| Sustainability | Eco-friendly; reduces textile waste and environmental impact. | Potentially higher waste production due to setup processes. |

Summary

DTF Transfers are revolutionizing the world of custom printing by providing an innovative approach that meets modern ecological and creative demands. With their impressive ability to create highly detailed and colorful designs without significant waste, DTF technology stands out as not only cost-effective but also sustainable. As more designers and businesses realize the efficiency and accessibility of DTF transfers, it is clear that this method is not just a trend but a foundational shift in how custom apparel will be produced in the future. Embracing DTF printing opens up new avenues for creativity, allowing for a broader range of designs and services that align with the growing market for personalized apparel.