In recent years, DTF transfers (Direct-to-Film transfers) have revolutionized the business printing solutions landscape, offering a modern approach to custom apparel printing. This innovative technique allows businesses to achieve high-quality, detailed prints that capture intricate designs with vibrant colors. One of the primary DTF printing advantages lies in its ability to cater to a diverse range of fabrics, making it an effective choice for various projects. However, as with any technology, it’s important to weigh the pros and cons of DTF, especially when considering factors like setup costs and durability. By exploring the unique benefits and challenges associated with DTF transfers, you’ll be better equipped to decide if this cutting-edge printing method is suitable for your brand in 2025.

Direct-to-Film printing, often referred to as DTF technology, represents a significant advancement in the realm of fabric printing. This method utilizes specialized films to seamlessly transfer designs onto textiles, catering to a growing demand for high-quality merchandise. With its versatility, businesses can explore various fabric options while benefiting from the quick production times that bypass traditional printing hardships. However, it’s essential to consider both the strengths and weaknesses associated with DTF printing, as this will equip business owners with the knowledge needed to navigate future printing projects effectively. By understanding the full scope of what DTF can offer, companies can determine how best to leverage this innovative printing solution.

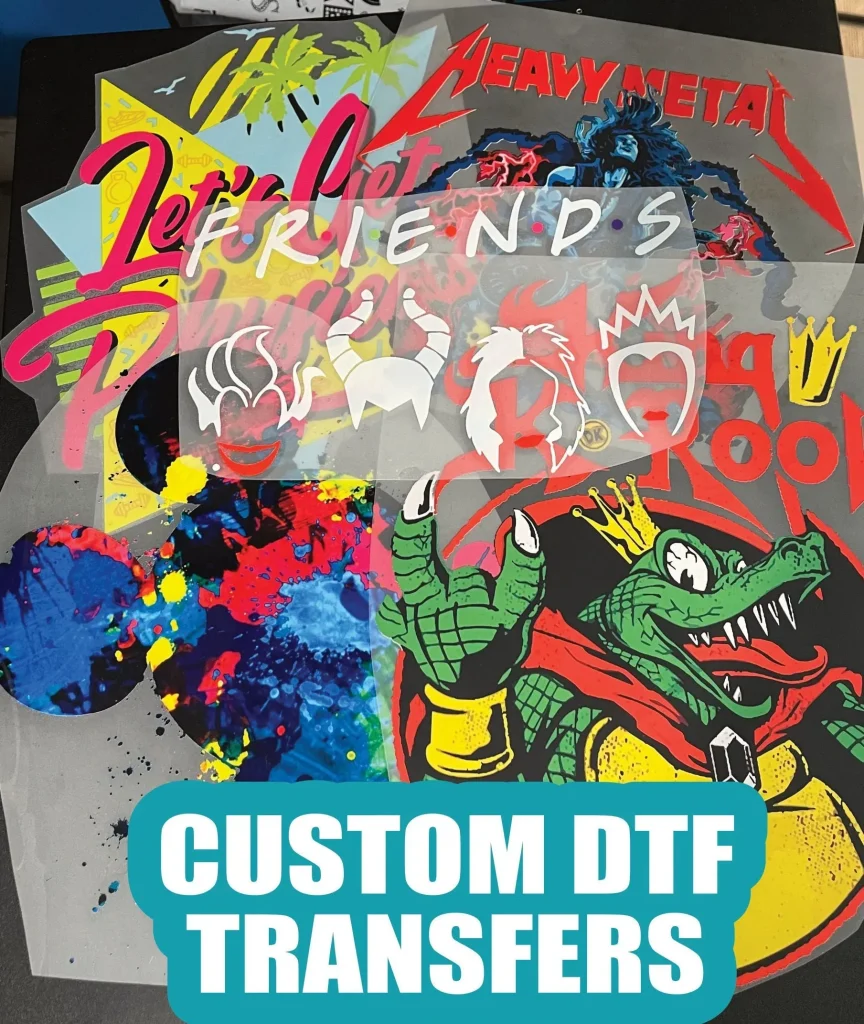

The Basics of DTF Transfers: A Comprehensive Overview

DTF transfers, short for Direct-to-Film printing, represent a revolutionary step forward in the world of custom merchandise production. Unlike traditional printing methods, which often require intricate setups and years of practice, DTF printing streamlines the entire process, making high-quality printing efficient and accessible. This technology uses a specialty film that accepts water-based inks to create vivid designs, suitable for a variety of fabrics, from cotton to polyester blends.

Due to its innovative approach, DTF printing not only allows businesses to produce eye-catching apparel but also ensures that the production method is eco-friendlier than many alternatives. Users benefit from reduced setup costs and minimal material waste, contributing to a more sustainable printing solution without compromising quality. As more entrepreneurs explore custom apparel printing, understanding DTF’s core principles becomes crucial for those aiming to thrive in a competitive market.

Pros and Cons of DTF Transfers Explained

When diving into the pros and cons of DTF transfers, businesses must weigh various factors. Among the most significant advantages is the printing quality. DTF printing offers an unparalleled ability to capture intricate designs and vibrant colors, making it particularly appealing for custom apparel. This high resolution means that logos, graphics, and even detailed illustrations come out looking crisp and professional, thus impressing customers and setting brands apart in a saturated marketplace.

Conversely, while DTF transfers have numerous upsides, there are also potential downsides to consider. For instance, the durability of prints can sometimes fall short, especially under heavy use, which means businesses must pay close attention to care instructions to maintain customer satisfaction. Additionally, the initial learning curve associated with mastering this printing method may pose challenges for those unfamiliar with the technology, necessitating some investment in training and experimentation.

Advantages of DTF Transfers for Your Business

DTF transfers stand out for their numerous advantages that can significantly benefit businesses in the apparel industry. One of the most attractive features is the overall printing quality. The technique delivers high-resolution prints with brilliant color saturation and detail, making it ideal for varied customizations. This is essential for businesses wanting to make a lasting visual impression with their merchandise, thereby driving customer engagement and sales.

Moreover, the versatility of DTF printing cannot be overstated. It’s compatible with a wide range of fabrics, which allows businesses to diversify their offerings without the constraints inherent in other printing methods. This enables brands to respond quickly to market trends and consumer demands, such as experimenting with different materials or fabric blends, ultimately leading to innovative product lines that can capture consumers’ attention and loyalty.

The Eco-Friendly Aspect of DTF Printing

As sustainability becomes increasingly important to consumers, DTF printing offers an eco-friendly alternative to traditional printing methods. Using water-based inks, this technique minimizes harmful environmental impacts commonly associated with solvent-based inks, making it attractive for brands looking to enhance their sustainability credentials. The shift towards greener practices is not only beneficial for the planet, but it could also improve a company’s brand image among environmentally conscious consumers.

Additionally, by reducing waste through streamlined printing processes and using less harmful materials, businesses engaging in DTF printing can appeal to a broad spectrum of customers. With growing demand for sustainable practices in business operations, adopting eco-friendly printing solutions like DTF can serve as a compelling selling point in marketing strategies, setting brands apart in an increasingly crowded marketplace.

Overcoming Challenges in DTF Printing

While DTF transfers present several advantages, there are inherent challenges that businesses must address to maximize their potential. One of these challenges is the durability of prints, as some users report fading or wear-and-tear after repeated washing. For brands focusing on custom apparel meant for everyday wear, ensuring that the durability of DTF prints aligns with customer expectations is critical to maintaining satisfaction and building a loyal customer base.

Furthermore, as with any new technology, the learning curve associated with DTF printing can prove daunting for some. Mastering the correct transfer temperatures and times for optimal results takes practice, making initial education crucial for businesses looking to implement this technology efficiently. Developing a robust training program or collaborating with experienced professionals in the field can help brands to overcome initial hurdles, ensuring they realize the full advantages of DTF printing without significant setbacks.

Choosing the Right Equipment for DTF Printing

Investing in the right equipment is essential for businesses aiming to leverage DTF printing effectively. Although the initial setup costs are generally lower than that of traditional printing methods, the required machinery and materials can carry a significant upfront expense. Understanding your specific needs, such as the volume of prints and the complexity of designs, can assist in making informed choices about the technology investments that will yield the best return.

Additionally, it’s vital to conduct thorough research on different DTF printers and supplies available in the market. This includes evaluating features, compatibility with various fabrics, and even customer support from manufacturers. Such diligence allows businesses to choose reliable equipment that not only meets current demands but is also scalable for future growth, thereby solidifying their position in the competitive business printing solutions landscape.

Frequently Asked Questions

What are DTF transfers in the context of custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing technology that allows for high-quality designs to be transferred onto textiles. This method utilizes specialized films printed with eco-friendly water-based inks, making it ideal for custom apparel printing due to its ability to produce vibrant and intricate designs.

What are the advantages of using DTF printing for business printing solutions?

DTF printing offers several advantages for business printing solutions, including high-resolution graphics, versatility across different fabric types, lower setup costs compared to traditional printing methods, no need for weeding, and an environmentally friendly approach through the use of water-based inks.

What are some disadvantages of DTF transfers I should be aware of?

Some disadvantages of DTF transfers include potential durability issues, particularly with fading after multiple washes, an initial learning curve for optimal printing techniques, higher upfront equipment costs, limited application suitability for specific projects, and risks of adhesion problems if not executed correctly.

How does DTF printing compare to screen printing in terms of quality?

DTF printing typically excels over screen printing when it comes to producing detailed, vibrant designs, especially for custom apparel. While screen printing can provide durable results for larger batches, DTF offers a quicker and more flexible alternative that retains high-quality outputs without the complexities of setup.

Are DTF transfers environmentally friendly?

Yes, DTF transfers are considered environmentally friendly because they use water-based inks instead of solvent-based inks commonly found in traditional printing methods. This aligns with increasing consumer demand for sustainable printing options, making DTF an attractive choice for eco-conscious businesses.

What kind of learning curve should I expect with DTF printing?

The learning curve for DTF printing mainly involves mastering the specific temperatures and transfer times necessary for successful prints. While DTF technology is generally user-friendly, businesses may need some initial experimentation to perfect the process and ensure high-quality results.

| Key Points | |

|---|---|

| Advantages of DTF Transfers | Disadvantages of DTF Transfers |

| 1. High Quality and Detail: Produces vibrant colors and intricate designs, ideal for custom products. | 1. Durability Concerns: Prints may fade after several washes if not cared for properly. |

| 2. Versatility: Can be used on various fabric types, including cotton and polyester. | 2. Initial Learning Curve: Requires understanding of optimal printing conditions. |

| 3. Lower Setup Costs: More affordable entry point compared to screen printing. | 3. Equipment Costs: Initial investment for printers and materials can be high. |

| 4. No Weeding Required: Speeds up production time, improving efficiency. | 4. Limited Specific Applications: Not suitable for every project; some methods may perform better. |

| 5. Eco-Friendliness: Uses water-based inks, making it a greener option. | 5. Potential for Adhesion Issues: Quality can vary based on process accuracy and settings. |

Summary

DTF transfers represent a modern and innovative approach for businesses looking to expand their printing capabilities, especially in the custom merchandise sector. Offering high-quality prints, versatility in fabric compatibility, and cost-effective setup options, DTF transfers are becoming increasingly popular among entrepreneurs and established companies alike. However, businesses must weigh potential durability issues, the cost of necessary equipment, and the learning curve associated with mastering this technology. By understanding both the advantages and challenges associated with DTF transfers, companies can make an informed decision about integrating this method into their operations in 2025 and continue to thrive in a competitive market.