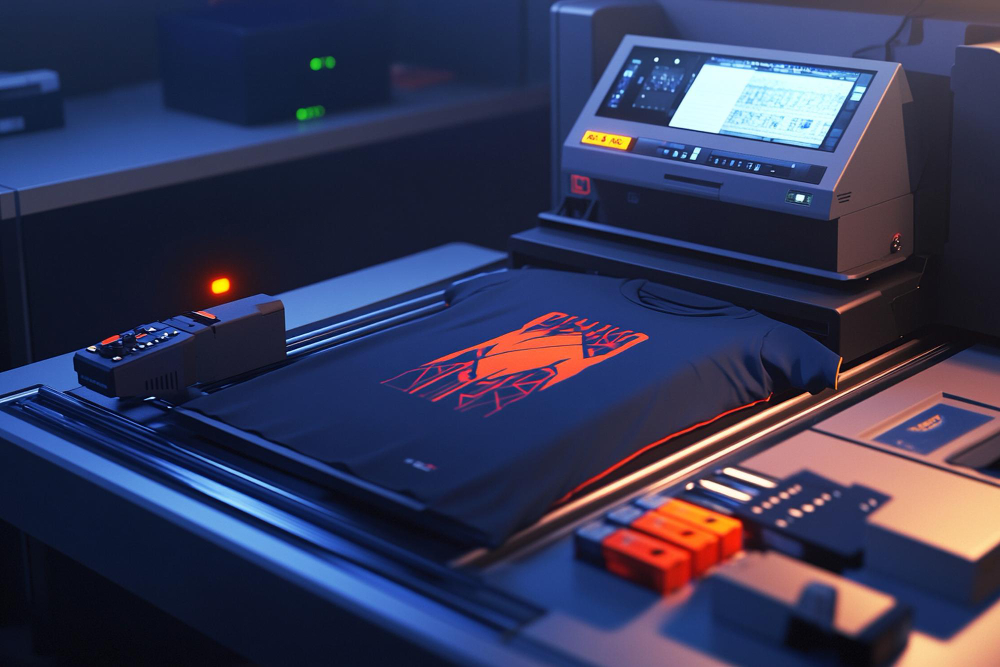

In the world of printing technology, UV DTF (Direct to Film) technology is revolutionizing the industry with its remarkable capabilities and numerous benefits. This innovative approach not only ensures high-quality prints but also provides sustainable printing solutions that are environmentally friendly. With its versatility in printing on various substrates, such as textiles and plastics, UV DTF technology enables businesses to create customizable printing options that meet diverse consumer needs. Furthermore, the UV printing advantages, such as durability and resistance to wear, ensure that printed materials maintain their vibrant appearance over time. As more companies recognize these benefits of UV printing, the demand for this cutting-edge technology continues to grow, solidifying its place in the future of the printing sector.

UV DTF printing technology, also known as ultraviolet direct-to-film printing, represents a significant shift in how prints are produced, merging efficiency with eco-conscious methods. This technique combines the elements of traditional UV printing and direct-to-film processes, allowing for the creation of intricate, high-resolution designs on a variety of materials. By employing ultraviolet light for curing inks, this method offers a robust solution that maximizes durability while minimizing environmental impact. Enhanced by its customizable nature, UV DTF serves as a flexible solution for businesses looking to adapt to evolving market demands. As we delve deeper into the specifics of this innovative technology, we uncover its numerous advantages that position it as a leader in modern printing practices.

Understanding the Advantages of UV Printing

UV printing technology boasts numerous benefits that make it a favorite among businesses seeking efficient and high-quality printing solutions. One of the main advantages is its ability to create vibrant prints with sharp detail and clarity. This is achieved through the use of ultraviolet light, which cures inks immediately upon contact with suitable surfaces. As a result, businesses can produce eye-catching graphics that capture attention and enhance brand visibility, effectively leading to increased customer engagement.

Additionally, UV printing is incredibly versatile, catering to a wide variety of materials, including plastics, wood, metal, and textiles. This adaptability allows for endless creative possibilities, enabling companies to expand their product lines and offer customized solutions. Furthermore, UV printing technology is typically faster than traditional methods, making it an ideal choice for businesses with tight deadlines or those looking to keep pace with the demands of modern consumers.

Exploring UV DTF Technology

UV DTF (Direct to Film) technology represents a fusion of the advantages found in both UV printing and the DTF approach, maximizing the strengths of each. Through this innovative method, intricate designs can be printed on an extensive range of surfaces while maintaining the durability that UV prints are known for. The unique curing process allows prints to adhere firmly to various materials, ensuring that vibrant colors remain intact over time, even with regular use.

Moreover, this technology simplifies the printing process, reducing the need for excessive setup time typically associated with other printing methods. As businesses strive to meet demand quickly, UV DTF technology stands out by offering rapid production capabilities that enhance overall efficiency and output. This technology not only allows for high-quality prints but also ensures that operational costs are kept in check, benefiting businesses in competitive markets.

Sustainable Printing with UV DTF

Sustainability has become a crucial factor in consumer decision-making, and UV DTF technology is well-suited to meet these eco-friendly demands. Utilizing UV inks results in lower emissions of volatile organic compounds (VOCs) compared to traditional printing methods. This means that organizations adopting UV DTF practices can significantly reduce their environmental footprint, appealing to eco-conscious customers while complying with increasingly stringent environmental regulations.

Investing in sustainable printing solutions isn’t just about meeting consumer preferences; it is also a smart business strategy. As customers become more aware of environmental issues, companies that prioritize eco-friendly practices are more likely to build customer loyalty and trust. By incorporating UV DTF technology into their operations, businesses not only contribute to environmental sustainability but can also position themselves favorably against competitors who may lag in this essential area.

Quality and Durability with UV DTF

Quality is paramount in the printing industry, and UV DTF technology excels in delivering high-quality prints that stand the test of time. The curing process involved in UV DTF ensures that inks adhere better and are less prone to fading, even in adverse conditions. This means that products printed with UV DTF technology are not only visually appealing but also reliable and durable, making them suitable for both indoor and outdoor applications.

Furthermore, the ability of UV DTF to withstand everyday wear and tear enhances its appeal to businesses looking to provide lasting products to their customers. For instance, printed materials used in outdoor signage or promotional items need to endure various environmental conditions without degrading in quality. By leveraging the strength of UV DTF, companies can reassure their clients that their purchases will maintain their integrity longer, thereby reinforcing brand loyalty and trust.

Enhanced Efficiency Through UV DTF

The efficiency of UV DTF technology plays a critical role in modern printing operations, greatly influencing how businesses manage production timelines. Unlike traditional printing techniques that often require significant setup and drying times, UV DTF allows for instant drying due to ultraviolet curing. This not only speeds up the turnaround time for projects but also increases overall workflow efficiency, enabling businesses to produce more output within shorter timeframes.

Additionally, UV DTF technology minimizes downtime, which is essential for companies looking to optimize their output. By streamlining the printing process, organizations can quickly transition from one project to another, facilitating rapid production cycles that can adapt to fluctuating market demands. This level of efficiency might be the difference between fulfilling large orders promptly or falling behind competitors in a fast-paced industry.

Customizable Printing Solutions with UV DTF

Customization is key in today’s market, where consumer preference leans heavily toward personalized products. UV DTF technology allows businesses to offer customizable printing solutions that can cater to individual customer needs, whether it’s for name and number printing on apparel or bespoke designs for promotional materials. This versatility in customization not only attracts a wider customer base but also enhances the perceived value of products offered.

Furthermore, the ability to change designs quickly and efficiently makes UV DTF technology an invaluable tool for businesses aiming to differentiate themselves in a saturated market. By leveraging the benefits of UV DTF, companies can experiment with various designs and ideas, leading to innovative product lines that resonate with consumers’ tastes and preferences, ultimately driving sales and boosting brand image.

Frequently Asked Questions

What are the key benefits of UV DTF technology in modern printing?

UV DTF technology offers several key benefits, including high quality prints that exhibit vibrant colors and intricate details. Additionally, its versatility allows it to print on various substrates like textiles, plastics, and metals, making it ideal for customizable printing solutions. Furthermore, this technology is eco-friendly, utilizing UV inks that emit fewer VOCs, aligning with sustainable printing solutions.

How does UV DTF technology enhance print durability compared to traditional methods?

The durability of prints using UV DTF technology is significantly enhanced thanks to the UV curing process, which solidifies inks for strong adhesion. This makes UV DTF prints resistant to fading, moisture, and physical wear, ensuring that products maintain high quality over time, especially for outdoor or frequently used items.

Is UV DTF technology a sustainable printing solution?

Yes, UV DTF technology is considered sustainable due to its use of eco-friendly UV inks that produce fewer volatile organic compounds (VOCs) than traditional solvent-based inks. This aspect reduces the environmental impact of the printing process, making it suitable for businesses that prioritize sustainable printing solutions.

What are the customization capabilities of UV DTF technology?

UV DTF technology excels in customization, offering the ability to produce intricate designs and vibrant colors across various substrates. This flexibility allows businesses to cater to diverse consumer preferences, which is essential in today’s market, where personalized products are in high demand.

How does UV DTF technology improve operational efficiency for businesses?

Operational efficiency improves with UV DTF technology through its rapid production cycles and minimized downtime, allowing businesses to fulfill large orders quickly. Compared to traditional methods like screen printing, UV DTF requires less setup time, thus enhancing workflow and ultimately contributing to improved customer satisfaction.

What advancements are expected in UV DTF technology in the coming years?

In the coming years, UV DTF technology is expected to see advancements such as enhanced automation and improvements in UV LED curing technology. These innovations will likely streamline production processes, enhance energy efficiency, and make UV DTF more accessible for various businesses, solidifying its position as a leading technology in the printing industry.

| Key Feature | Description |

|---|---|

| Versatility in Substrates | Able to print on textiles, plastics, metals, glass, and more. |

| Durability and Quality | Inks are UV cured making them resistant to fading, moisture, and wear. |

| Eco-Friendly Options | Utilizes UV inks with lower VOC emissions, reducing environmental impact. |

| Efficiency and Speed | Faster production cycles compared to traditional printing methods. |

| Reduced Waste | Minimal material waste due to precise printing and efficient use of transfer film. |

Summary

UV DTF Technology is revolutionizing the printing industry by offering remarkable advantages in quality, sustainability, and efficiency. This advanced printing method showcases versatility, allowing the production of high-quality prints on a variety of substrates such as textiles and plastics. As businesses increasingly seek eco-friendly solutions, UV DTF Technology stands out with its lower VOC emissions and durability, appealing to both manufacturers and consumers alike. Furthermore, its rapid production capabilities help fulfill market demands swiftly. Companies adopting UV DTF Technology will not only enhance their product offerings but also position themselves favorably in a competitive landscape, making it an essential investment for future growth.